Rotational flow pulverized coal burner

A technology for burners and swirl generators, which is applied in the direction of burners, burners for burning powder fuel, combustion methods, etc., which can solve the problems of high energy consumption, reduced effect of thick-thin separation, large resistance, etc., and achieve nitrogen oxide emissions The effect of low consumption, good combustion stability and high swirl intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

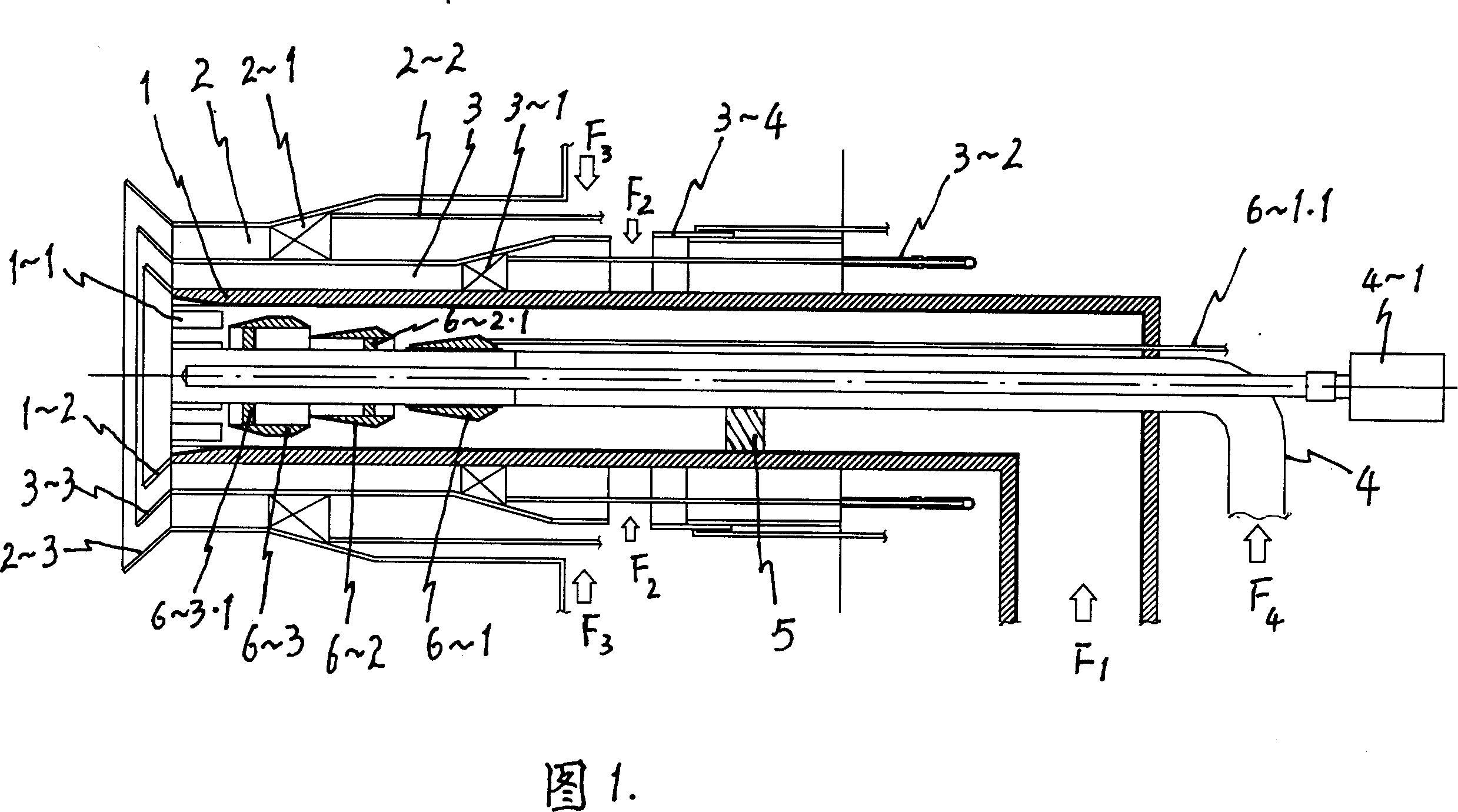

[0009] The total length of the burner is 7190mm, of which: the main body of the central cylinder 4 is 5160mm long, and 3 fixed plates 5 are arranged in the main nozzle 1 to fix the nozzle, the length of 4-1 oil gun is 6990mm, and the diameter of the pipe body is φ38mm. The main nozzle 1 is 4500mm long, the inner diameter of the nozzle cavity is φ590mm, and the wall thickness of the pipe body is 60mm. 30°, set 16 at equal arc intervals. The first-level thick-thin separation mechanism 6~1 has an axial length of 347mm, the maximum outer diameter φ315mm, and is slidably matched with the central cylinder 4 and adjusted axially by adjusting the pull rod 6~1.1. The second and final thick-thin separation mechanisms 6~2, 6~3 This embodiment is all fixed, through its supporting plates 6-2.1 and 6-3.1 and the central cylinder 4 are welded into one body, wherein the two-stage thick-lean separation mechanism 6-2 has an axial length of 335mm, and the inner and outer diameters are respective...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com