Preparing method and use of chitosan-containing nano fibrous tissue recovery support

A nanofiber and tissue repair technology, which is applied in the fields of scaffolds, medical science, and prostheses, can solve the problems of PVA being unable to degrade and fail to meet the mechanical properties of tissue repair, and achieve good mechanical properties, high porosity, and the effect of promoting rehabilitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

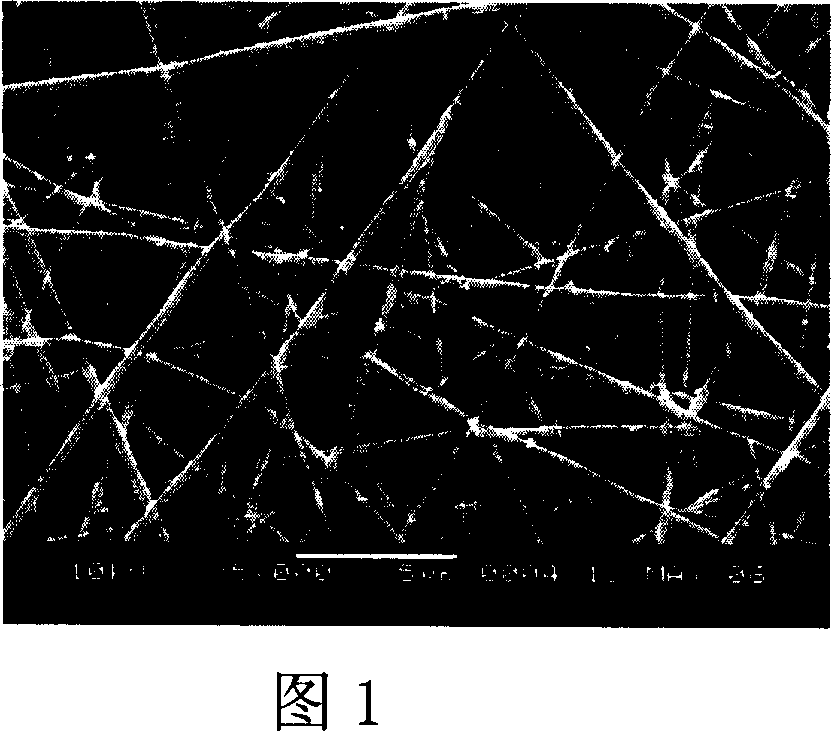

[0022]Dissolve 0.08 g of squid bone chitosan in 2 ml of HFIP / TFA (V / V, 9 / 1) mixed solvent, stir magnetically until completely dissolved, dissolve 0.08 g of P(LLA-CL) in 2 ml HFIP, stir magnetically until completely dissolved, After the two are completely dissolved, they are mixed at a volume ratio of 1:1, stirred evenly by magnetic force to obtain 4 ml of a mixed spinning solution with a total mass volume ratio of 4%. Inhale the mixed solution into the syringe, control the advance speed of the micro-injection pump to 0.6ml / h, select a No. 7 stainless steel needle and connect it to a 20KV high voltage, and use a grounded aluminum foil to receive the fiber filament at a distance of 13cm from the needle tip. After 6 hours, a disordered nanofiber film with an average diameter of about 205 nm was formed on the aluminum foil.

Embodiment 2

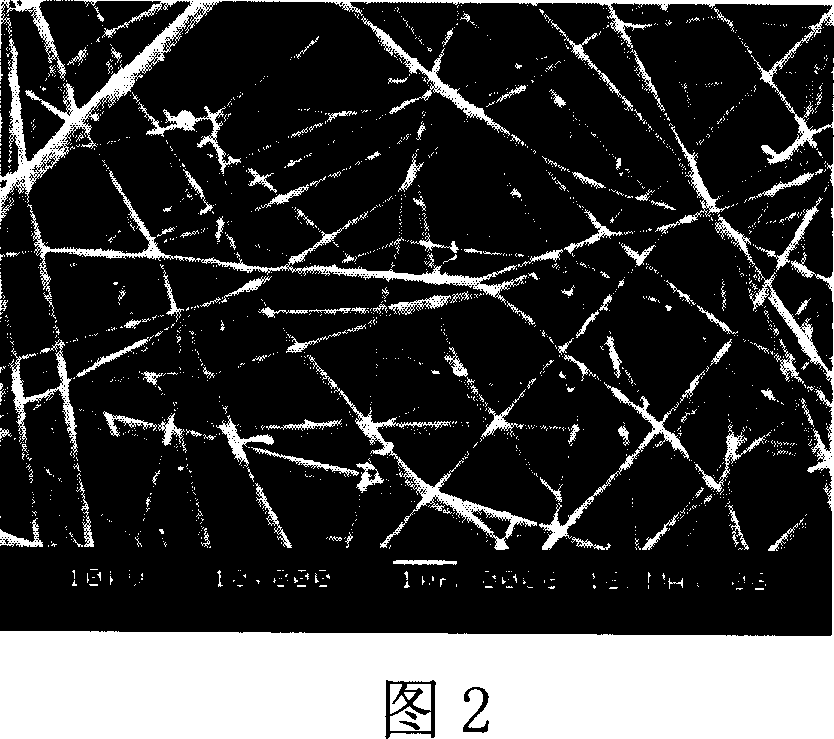

[0024] Dissolve 0.16 g of squid bone chitosan in 2 ml of HFIP / TFA (V / V, 9 / 1) mixed solvent, stir magnetically until completely dissolved; dissolve 0.08 g of P(LLA-CL) in 1 ml HFIP, stir magnetically until completely dissolved After the two are completely dissolved, mix by volume ratio 1: 2 (chitosan / P(LLA-CL)), magnetic stirring and mixing evenly obtain the total concentration of 8% mixed spinning solution 3ml, chitosan in its solute The mass ratio of / P(LLA-CL) was 1:2. Inhale the mixed solution into the syringe, control the advance speed of the micro-injection pump to 1ml / h, select a No. 9 stainless steel needle and connect it to a 20KV high voltage, and use a grounded aluminum foil to receive the fiber filament at a distance of 15cm from the needle tip. A film of disordered nanofibers was received on the aluminum foil after 3 hours.

Embodiment 3

[0026] Dissolve 0.02 g of crab shell chitosan in 1 ml of HFIP / FA (V / V, 9 / 1) mixed solvent, stir magnetically until completely dissolved; dissolve 0.02 g of P(LLA-CL) in 1 ml HFIP, stir magnetically until completely dissolved Dissolving; after the two are completely dissolved, uniformly mix, magnetically stir and mix evenly to obtain chitosan / P(LLA-CL) with a volume ratio of 1:1 and a total concentration of 2% mixed spinning solution 2ml. Inhale the mixed solution into the syringe, control the advance speed of the micro-injection pump to 0.5ml / h, select a No. 9 stainless steel needle and connect it to a 20KV high voltage, and use a grounded aluminum foil to receive the fiber filament at a distance of 20cm from the needle tip. After 4 hrs a film made of disordered nanofibers was received on the aluminum foil. In this scheme, the chitosan solution obtained by HFIP / FA (V / V, 9 / 1) has a high viscosity, and there are a few droplets during the spinning process of the mixed solution. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com