Adjustable femtosecond pulse generator in dual wavelengh synchronized accuratly

A pulse generator and femtosecond laser technology, applied in lasers, phonon exciters, laser parts, etc., can solve the problems of inability to meet ultrafast disciplines, and achieve the effects of easy start-up, simple operation and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

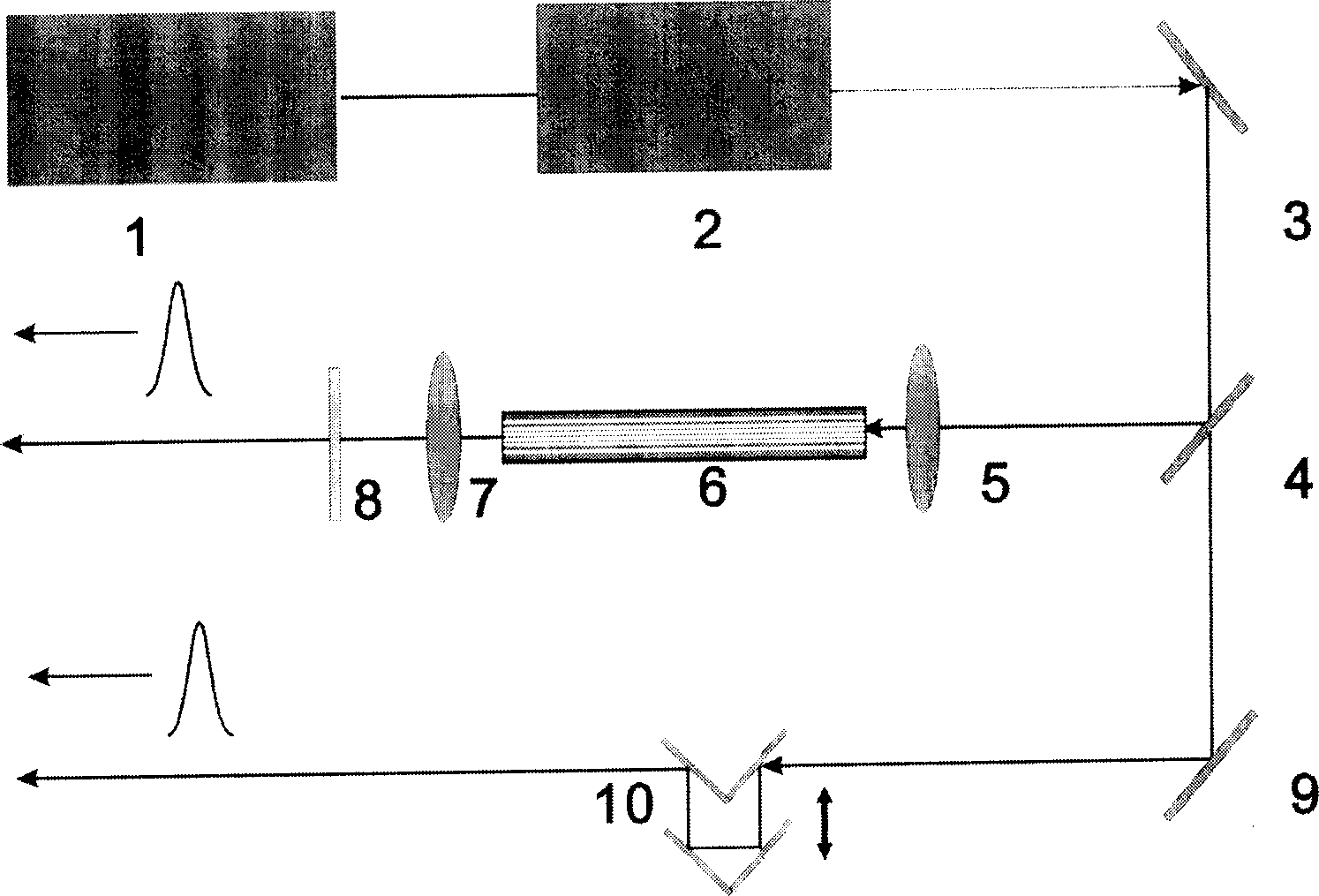

[0018] The present invention is described in detail below in conjunction with accompanying drawing:

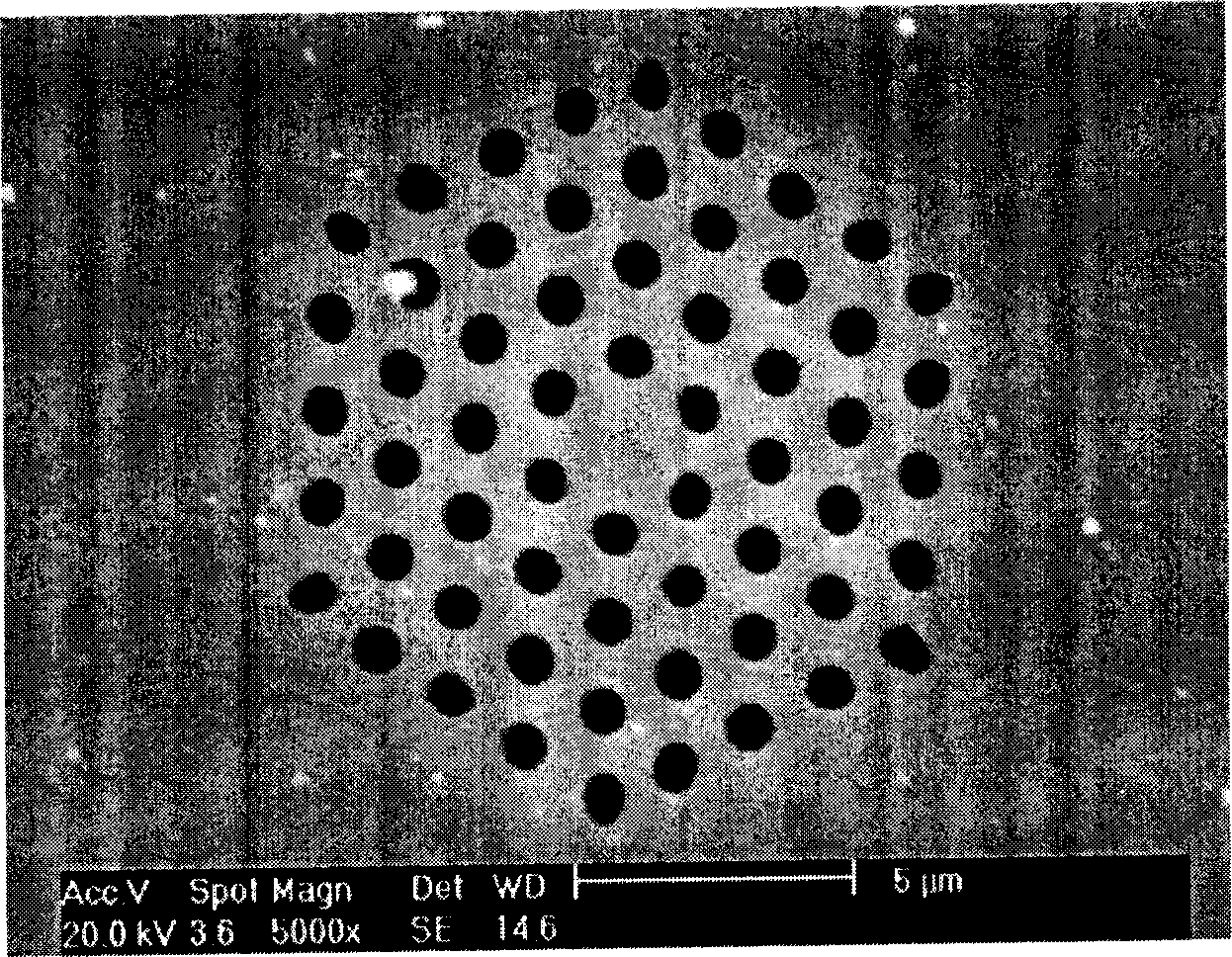

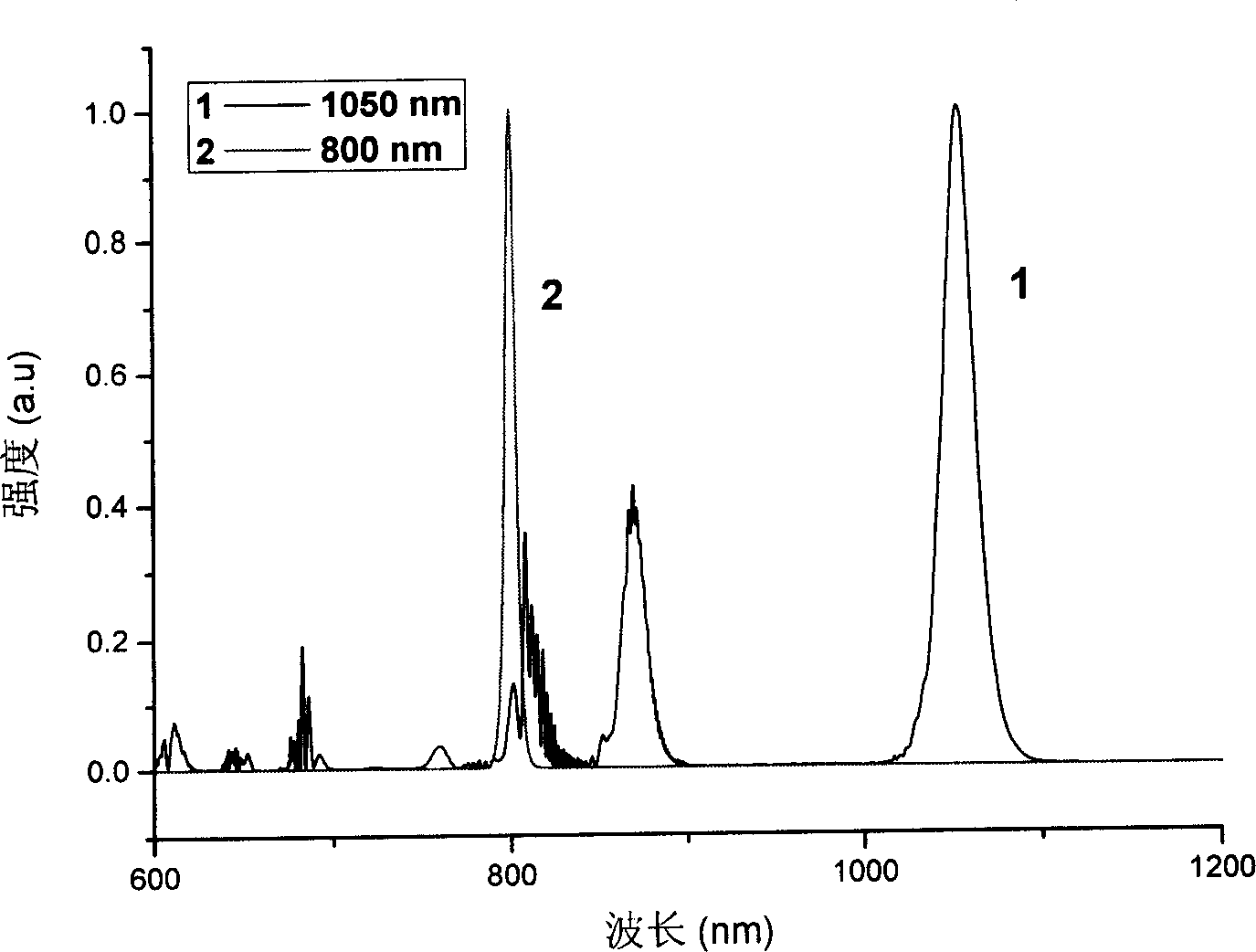

[0019] The whole set of instruments consists of a titanium-doped sapphire laser 1 that can stably output femtosecond laser pulses with a pulse width of 15-100 fs, a single pulse energy of 2-10 nJ, and a repetition rate of 60-120 MHz, and an isolator 2 that prevents the feedback light from affecting the mode-locking (by Faraday rotation) device, half-wave plate and polarizer), which can provide negative dispersion near the center wavelength of 800nm of the femtosecond laser output by the titanium-sapphire mode-locked laser. Microstructure fiber 6 with enhanced nonlinear effect and single-step precision Stage precision time delay compensation line 10 is composed. First, the femtosecond laser pulse output by the femtosecond laser is output to the coupling lens 7 through the isolator. The 800nm femtosecond laser is split into two beams using a beam splitter 4 with a reflectiv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com