Heat elimination type structure for packing complex crystal

A technology of flip-chip packaging and heat dissipation, which is applied in the direction of electrical components, electric solid-state devices, circuits, etc., and can solve problems such as product failure, product impact on performance, and inconvenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment

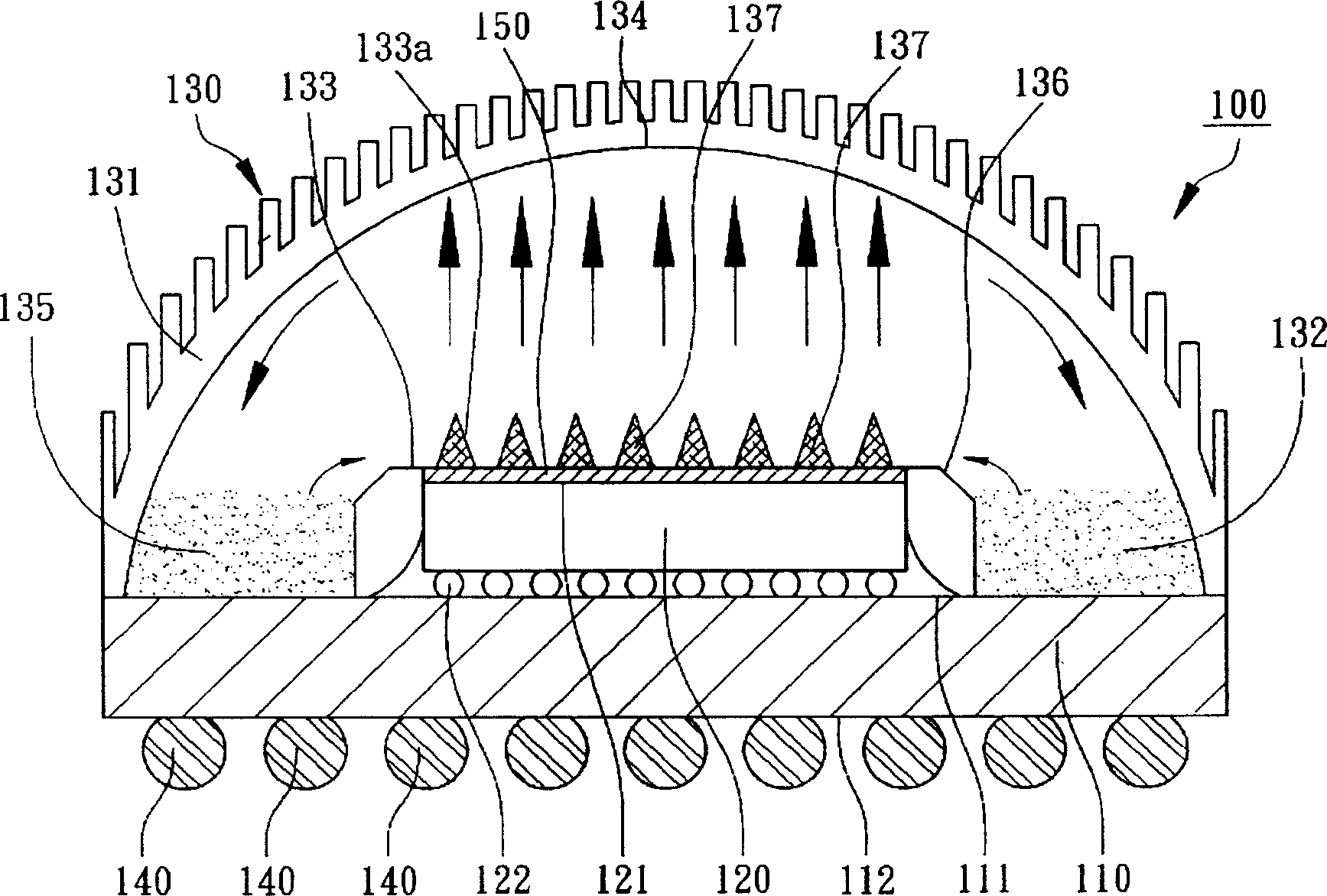

[0049] see figure 2 Shown is a first embodiment of the heat dissipation flip chip package structure of the present invention. The heat dissipation flip chip package structure 100 includes a substrate 110 , a flip chip 120 and a heat sink 130 . The substrate 110 has an upper surface 111 . In this embodiment, the heat dissipation flip chip package structure 100 includes a plurality of solder balls 140 disposed on the lower surface 112 of the substrate 110 . The flip chip 120 is bonded to the upper surface 111 of the substrate 110 , and the flip chip 120 has a back surface 121 . In this embodiment, the flip chip 120 is electrically connected to the substrate 110 through a plurality of bumps 122 .

[0050] The radiator 130 is arranged on the back surface 121 of the flip chip 120, wherein the radiator 130 includes a heat dissipation shell 131 and a coolant 132, the heat dissipation shell 131 is a closed space, and includes a bottom heat exchange part 133, A top heat exchange pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com