Flame-retardant polyamide composition and its use

A polyamide composition and flame retardancy technology, applied in the field of connectors with excellent heat resistance, can solve the problems of hindering continuous production, deteriorating color quality of resin compositions, unsatisfactory flame retardancy and color stability, and the like, Achieve the effect of reducing mold maintenance frequency, improving continuous productivity, and high industrial value

Active Publication Date: 2007-02-14

MITSUI CHEM INC

View PDF3 Cites 8 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In addition, when bromine-based flame retardants and antimony compounds are used together, in terms of productivity, a large amount of gas is generated during molding, which becomes the main cause of mold deposits, so frequent operations such as mold disassembly and cleaning are required, which hinders continuous production. main reason for productivity

In addition, the deterioration of the color quality of the resin composition due to the heat in the reflow soldering process is also a problem.

[0006] From this background, as substances that can replace antimony compounds, a variety of metal compounds have been proposed, and a flame-retardant resin composition in which part or all of the antimony compounds have been replaced by zinc borate has been proposed. Color stability cannot be satisfied

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1~ Embodiment 7

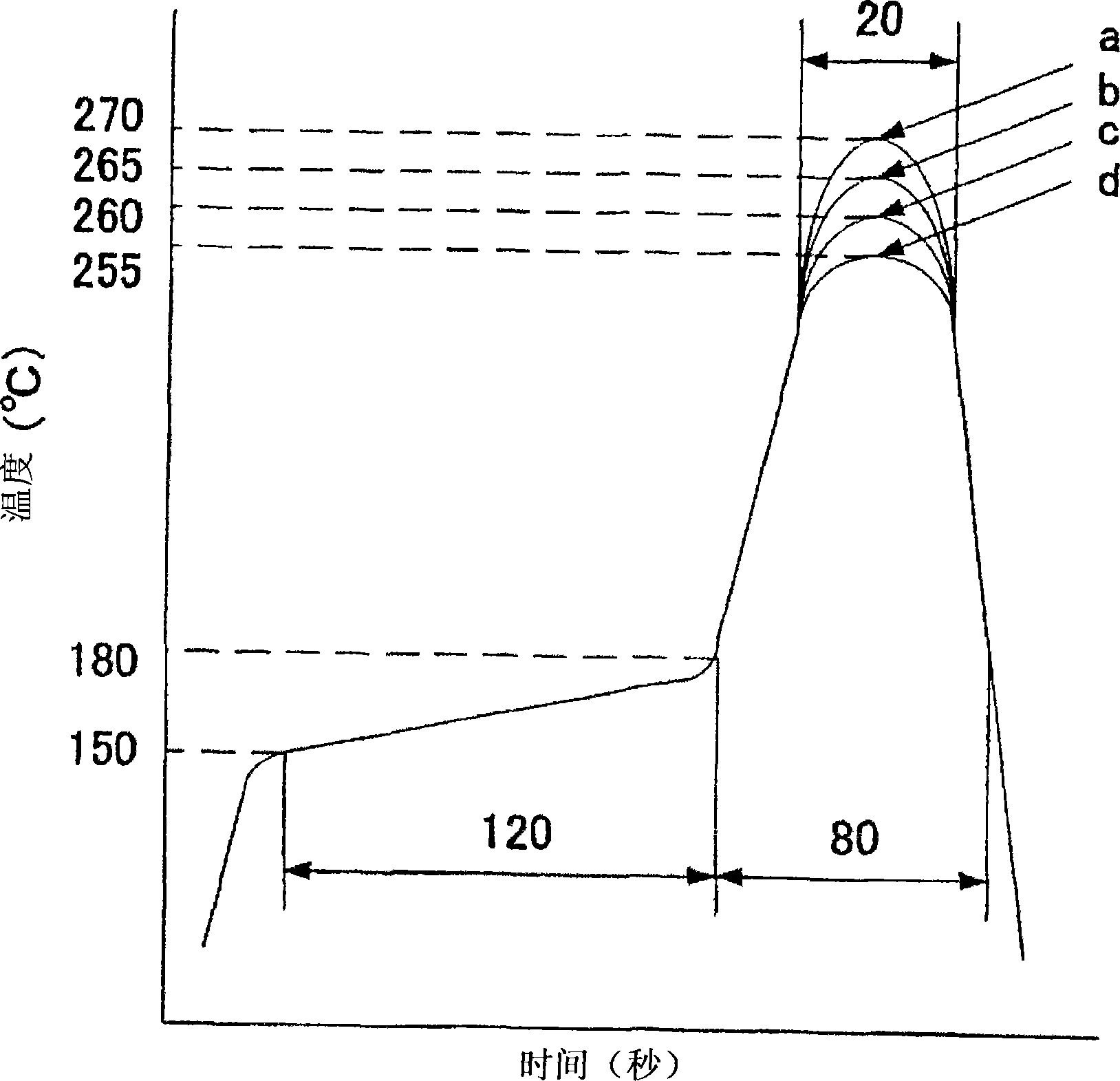

[0100] The above-mentioned components were mixed in the molar ratio shown in Table 1, and put into a biaxial extruder with a port set at a temperature of 320° C. to melt and knead to obtain a pellet-shaped composition. Next, properties of the obtained polyamide composition were evaluated, and the results are shown in Table 1.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| flow length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Login to View More

Abstract

Provided is a polyamide compound which is free from an environmental problem caused by an antimony compound and from a problem in a production process caused by the generation of a gas, which is a main cause of a mold deposit particularly in the case of the combination use with a flame-retardant containing bromine, and is excellent in flame-retardancy, toughness and melt fluidity, and also exhibits good heat resistance and good color stability in a reflow soldering step being required in the surface mounting, and thus is suitable for electric and electronic parts. A flame-retardant polyamide composition, characterized in that it comprises 10 to 80 mass % of a polyamide (A), 5 to 40 mass % of a flame retardant (B), 0.5 to 10 mass % of zinc borate and at least one other salt of zinc (C), 0 to 60 mass % of an inorganic reinforcing material (D) and 0 to 5 mass % of a drip preventing agent (E).

Description

technical field [0001] The present invention relates to a flame-retardant polyamide composition having excellent mechanical properties such as toughness, good melt fluidity, low hygroscopicity, excellent heat resistance and color stability in a reflow soldering process, and characterized by not using an antimony compound And electric and electronic parts formed from the composition. [0002] More specifically, the present invention relates to a flame-retardant polyamide composition suitable for forming electric and electronic components such as small-pitch connectors having a thin wall and a short distance between connecting terminals, and a polyamide compound formed from the composition having excellent heat resistance. Connector. Background technique [0003] Conventionally, as a raw material for forming electronic components, polyamide that can be melted by heating and formed into a predetermined shape has been used. Generally, nylon 6, nylon 66, etc. are widely used as...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C08L77/06C08K3/24C08K3/32C08K3/38

CPCC08K3/38C08L77/06C08K3/32

Inventor 大川由人

Owner MITSUI CHEM INC

Features

- Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com