Prestressed concrete steel pipe congruent pile and its manufacture and construction method

A technology of concrete steel pipes and concrete pipe piles, which is applied in sheet pile walls, foundation structure engineering, construction, etc., can solve the problems of soaring manufacturing costs, poor horizontal bearing capacity, and no prestress, so as to reduce construction costs and resist bending The effect of increased rigidity and reduced steel consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

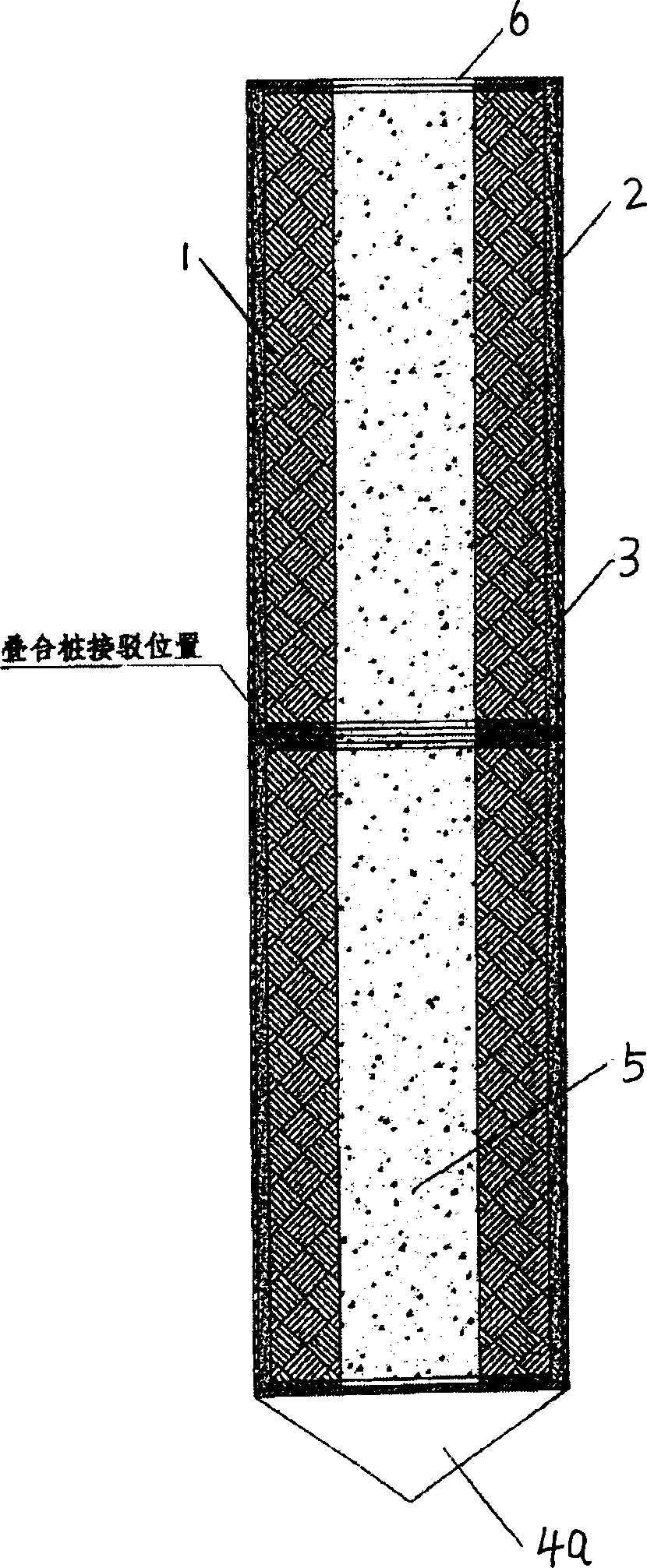

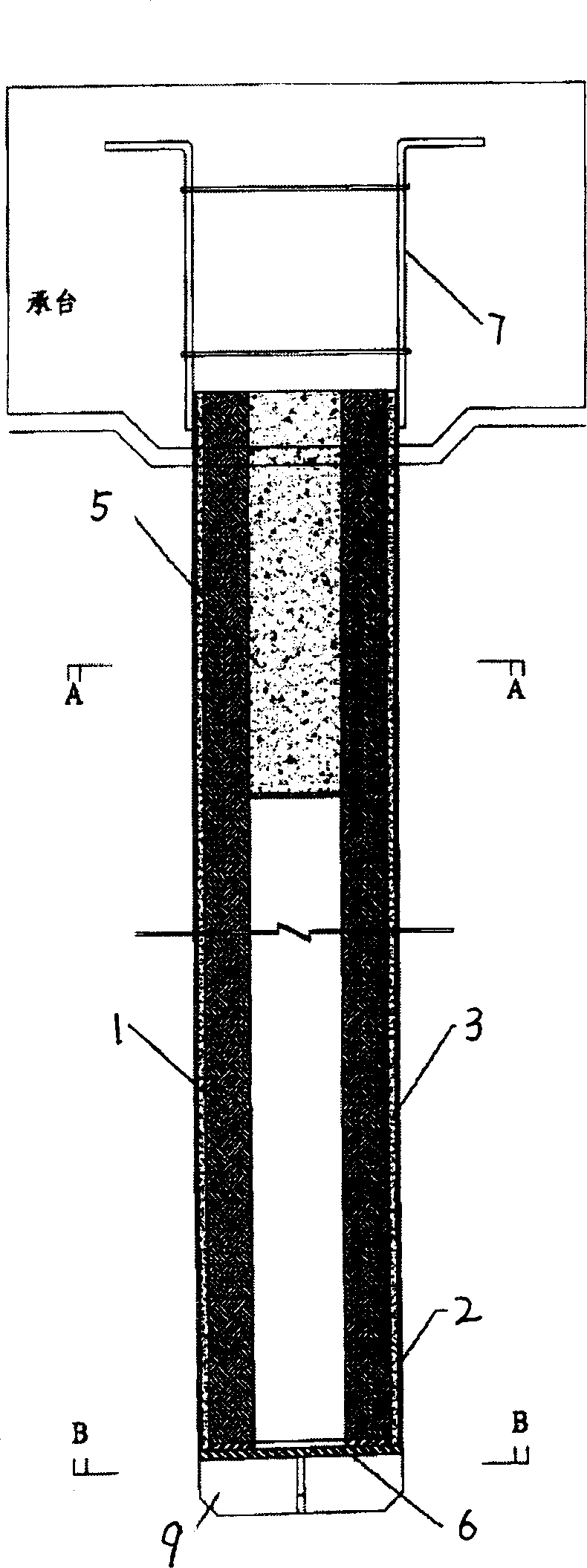

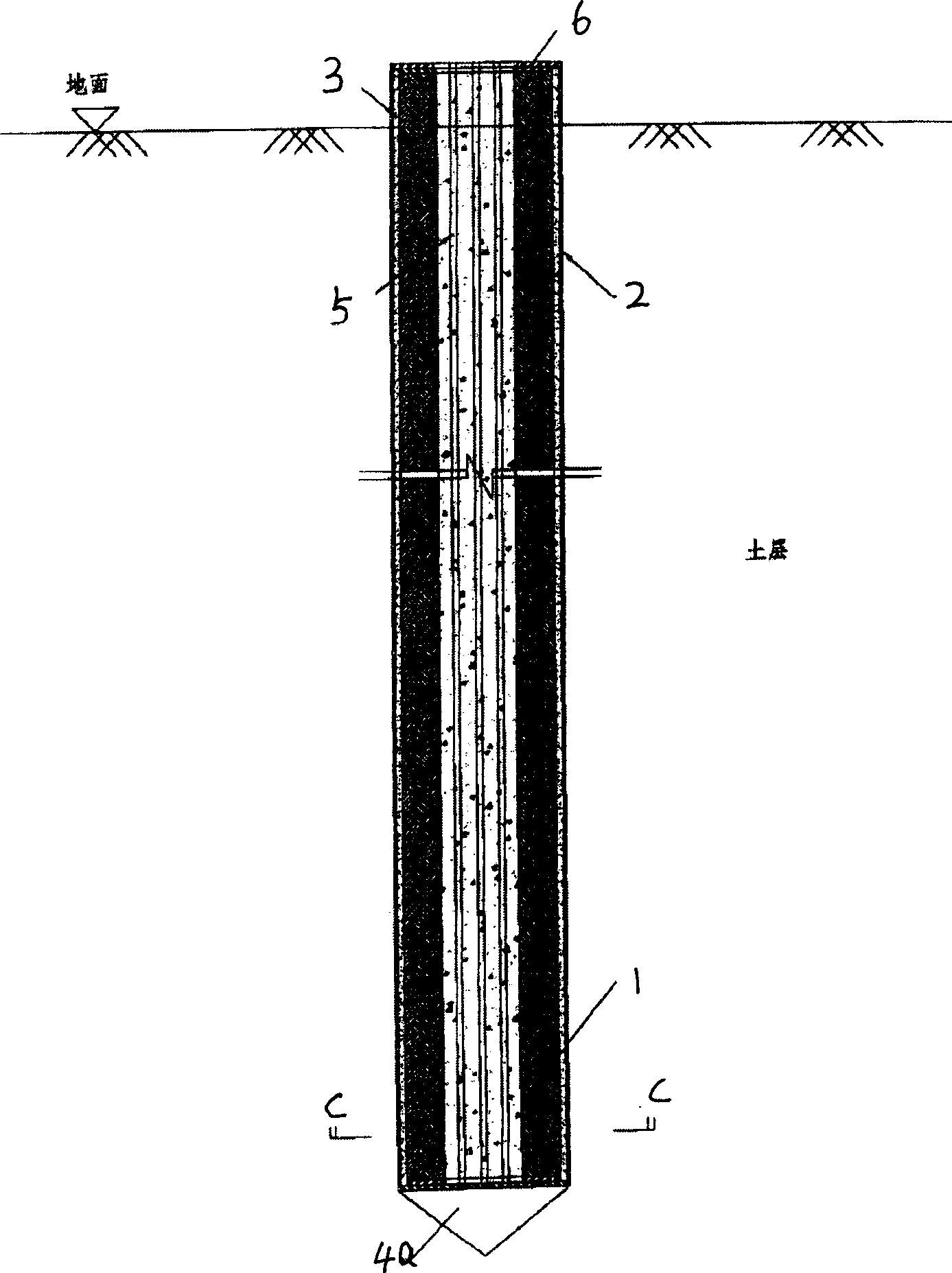

[0041] Such as Figure 1 to Figure 3 As shown, the prestressed concrete steel pipe composite pile includes: the finished prestressed concrete pipe pile 1, the permanent steel pipe 2 sleeved on its outside, and the end sealing parts 6 installed at both ends of the pile section; the steel pipe and the finished prestressed concrete pipe The piles are filled with grouting material 3; spud cans 4 are installed at the bottom of the whole pile.

[0042] The finished prestressed concrete pipe pile 1 is a pre-tensioned or post-tensioned prestressed concrete pipe pile, and its prestress value can be changed from the minimum value to zero according to the position of the pile section in the direction of the whole pile or according to the different construction stresses. Start adjusting upwards. The finished prestressed concrete pipe pile 1 adopts surfaces of different diameters, thicknesses and roughness levels, as well as concave and convex surfaces according to specific design require...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com