Over-magnetostriction rod drive membrane pump

A giant magnetostrictive rod and membrane technology, applied to pumps with flexible working elements, pumps, machines/engines, etc., can solve the problem of low power, etc., and achieve the effect of strong self-priming ability, no impact, and low noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

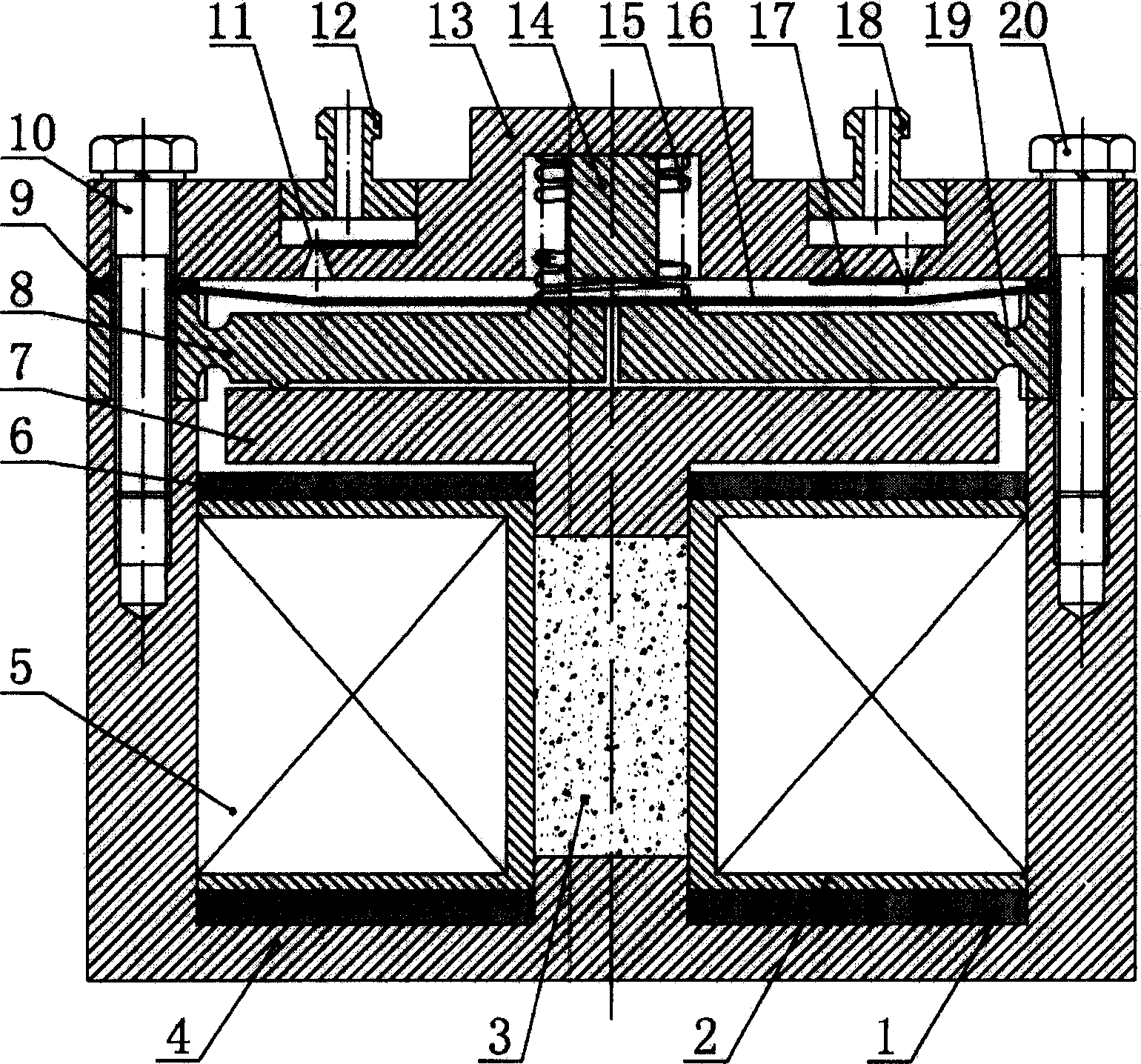

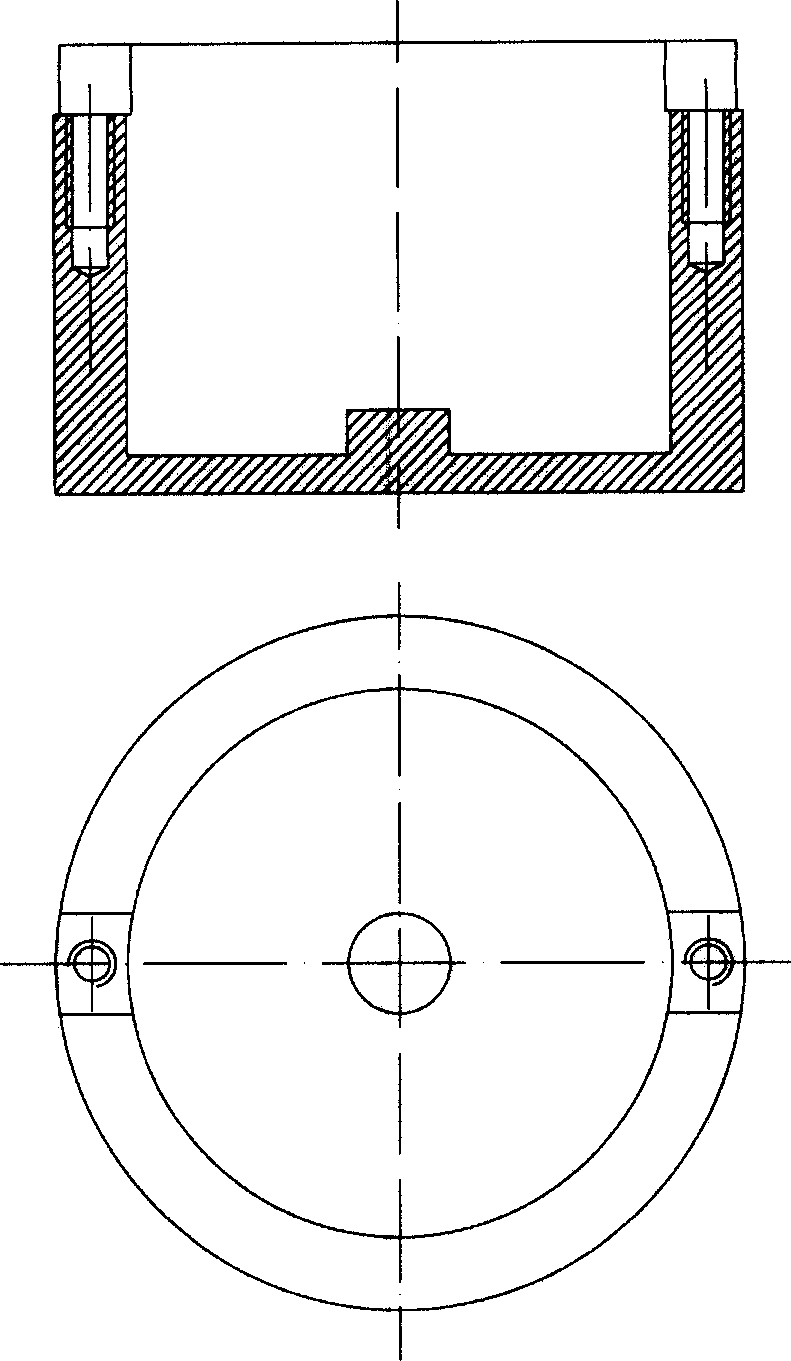

[0029] Such as figure 2 As shown, the present invention includes a lower permanent magnet 1, a bobbin 2, a giant magnetostrictive rod 3, a pump body 4, a drive coil 5, an upper permanent magnet 6, a top plate 7, a left displacement amplification mechanism 8, a sealing ring 9, a left Screw 10, outlet valve 11, outlet pipe 12, pump cover 13, cylinder block 14, spring 15, elastic diaphragm 16, inlet valve 17, water inlet pipe 18, right displacement amplification mechanism 19, right screw 20.

[0030] A circular elastic diaphragm 16 and an annular sealing ring 9 are installed between the barrel-shaped pump body 4 and the pump cover 13. The elastic diaphragm 16 divides the inner cavity of the pump body 4 into upper and lower parts. The cavity between the elastic diaphragm 16 and the pump cover 13 is the pump working chamber. Inside the cavity between the elastic diaphragm 16 and the pump body 4, a left displacement amplification mechanism 8 and a right displacement amplification ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com