Carbon nano-tube preparation method and apparatus

A technology of carbon nanotubes and preparation devices, which is applied in the direction of nanostructure manufacturing, nanotechnology, nanotechnology, etc., and can solve the problems of different lengths of carbon nanotubes, inconsistent emission electron characteristics of carbon nanotubes, and poor brightness uniformity of displays, etc. problem, to achieve the effect of uniform length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0035] see Figure 1 to Figure 4 , the first embodiment of the present invention provides a method for preparing carbon nanotubes, which includes the following steps:

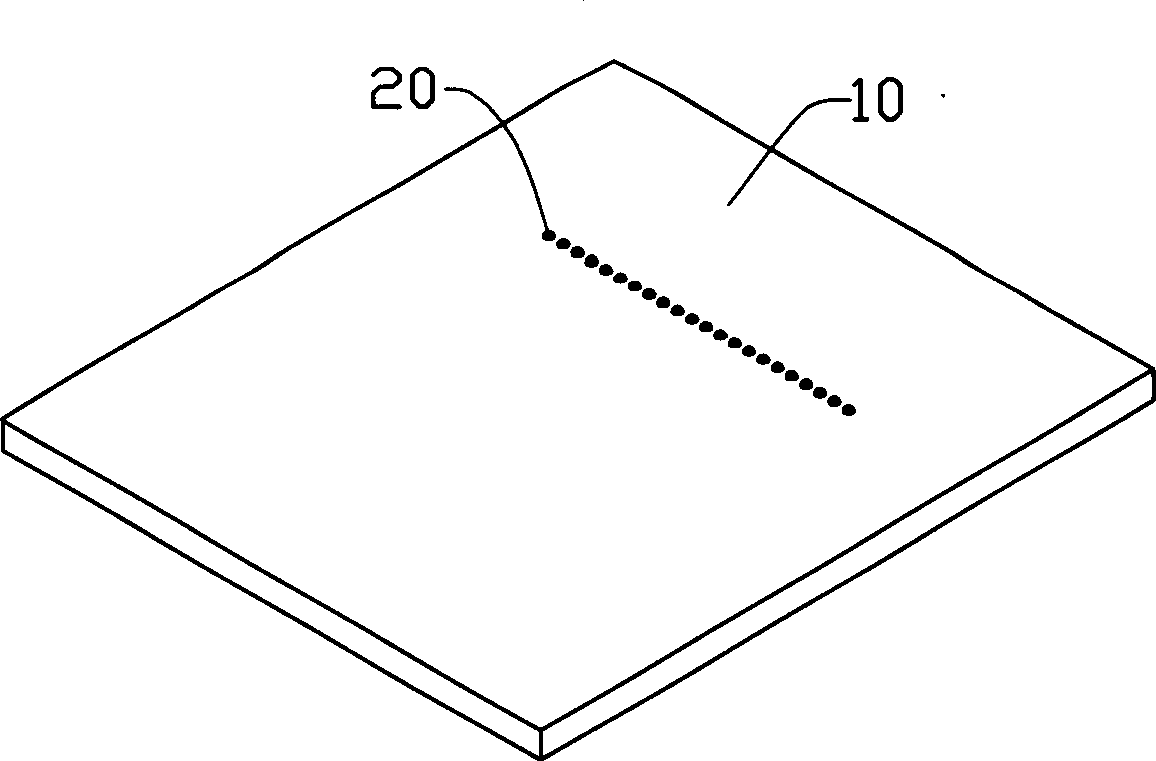

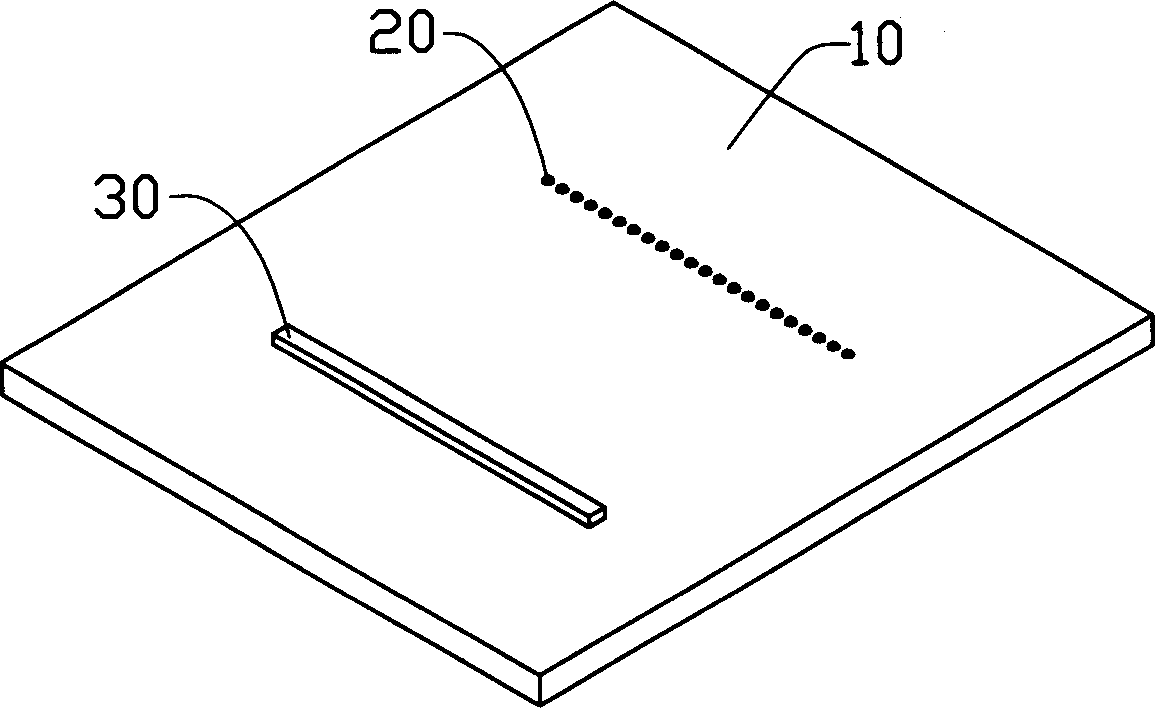

[0036] (1) see figure 1 , providing a substrate 10 on which a catalyst particle array 20 is formed. The substrate 10 can be made of semiconductor materials such as silicon wafers, III-V compound wafers and the like. The catalyst particles in the catalyst particle array 20 are preferably arranged in a straight line. Of course, the catalyst particles in the catalyst particle array 20 can be arranged such that the distances between them and the subsequently formed electrodes are substantially equal. The catalyst particles can be made of iron, cobalt, nickel, or their alloys. The catalyst particle array 20 will serve as a catalyst for the subsequent growth of carbon nanotubes. Wherein, the formation method of the catalyst particle array 20 can adopt the screen printing method; the following method can also be ...

no. 2 example

[0045] The second embodiment of the present invention is basically the same as the first embodiment, the difference lies in the modification of step (1) and step (2) of the first embodiment. The preparation method of the carbon nanotube of the present embodiment comprises the following steps:

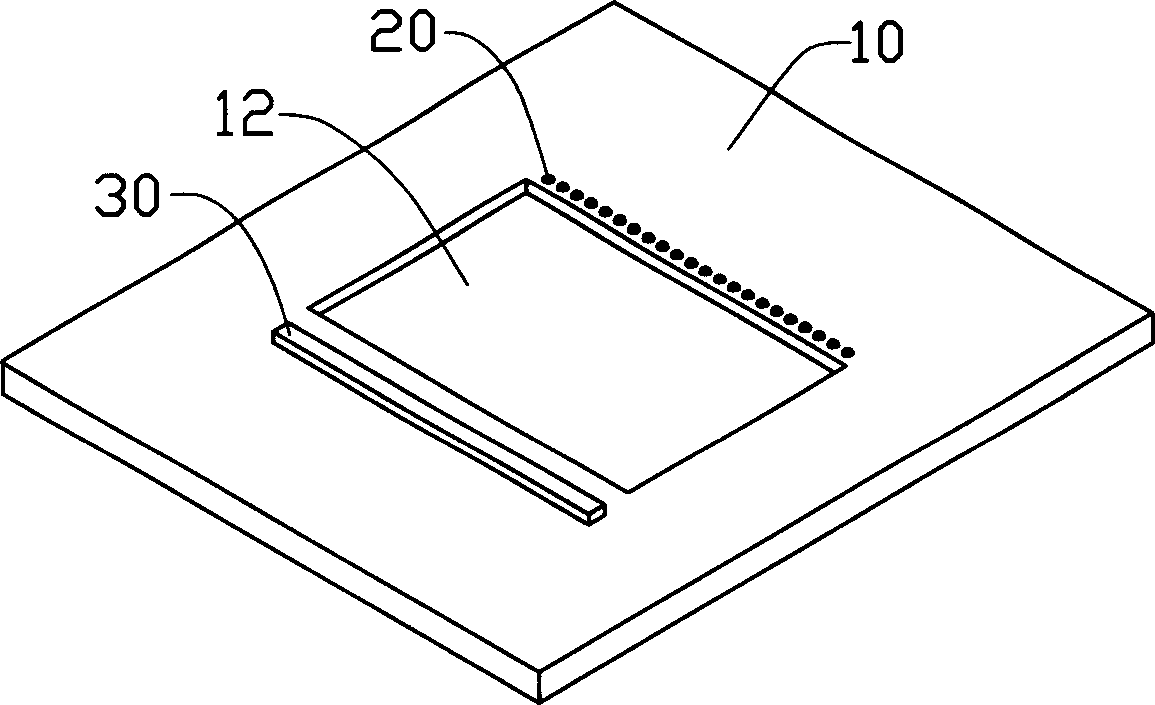

[0046] (1) A substrate is provided, which has a surface; and a groove is formed on the surface of the substrate. Generally speaking, the growth length of carbon nanotubes prepared by chemical vapor deposition can be several nanometers to several micrometers; therefore, the width of the groove in this embodiment can be set to several nanometers, or even several micrometers; Depends on the length. Generally speaking, the depth of the groove is preferably greater than 1 μm.

[0047] (2) An array of catalyst particles is formed on the substrate surface on one side of the groove, and an electrode is formed on the substrate surface on the opposite side of the groove. The electrode is posit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com