Rope brake system of elevator by using cam

A wire rope and brake technology, which is applied to elevators, lifts, transportation and packaging in buildings, etc., can solve problems such as troubles in on-site installation operations and difficulties in installation operations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with the accompanying drawings.

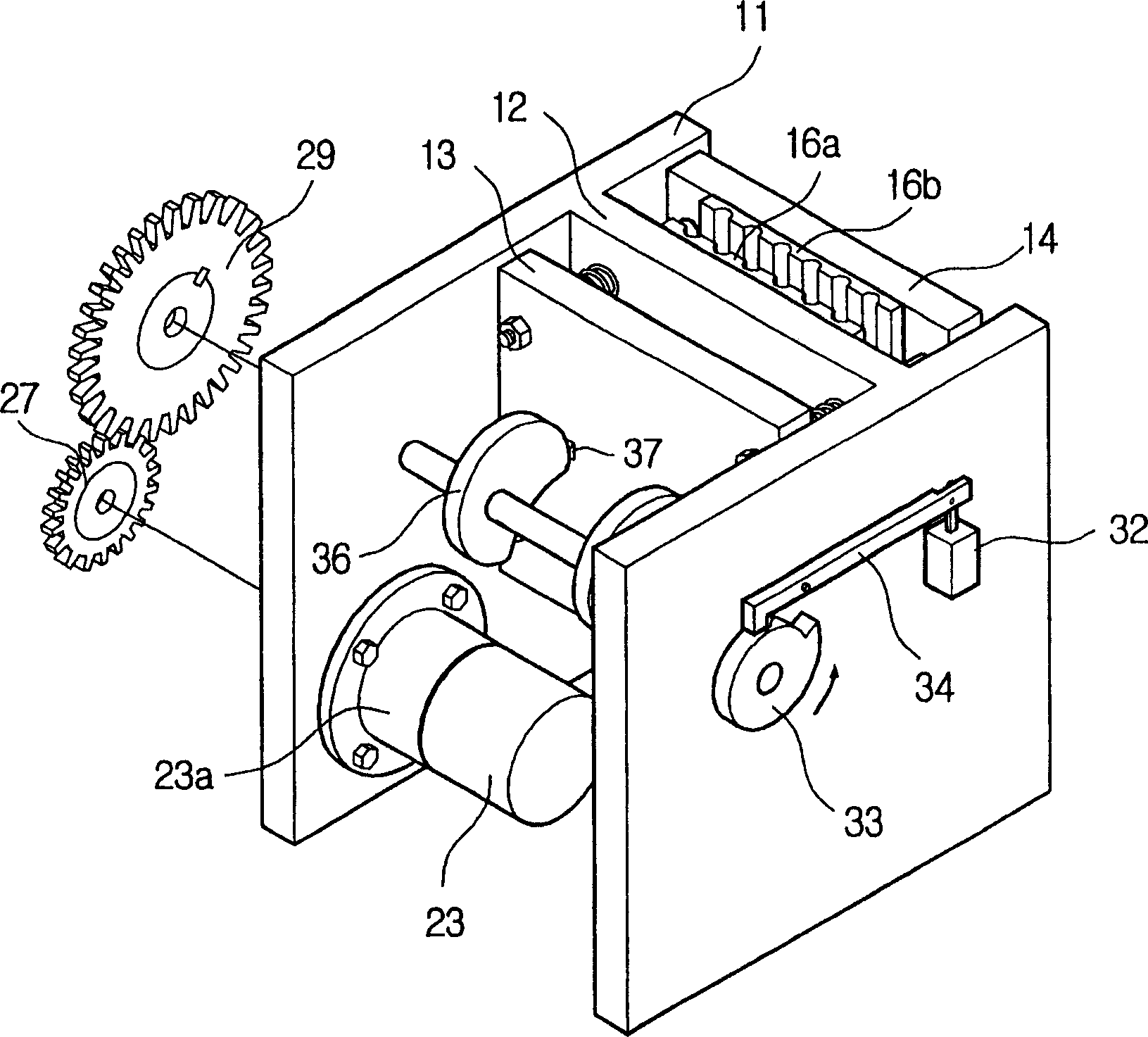

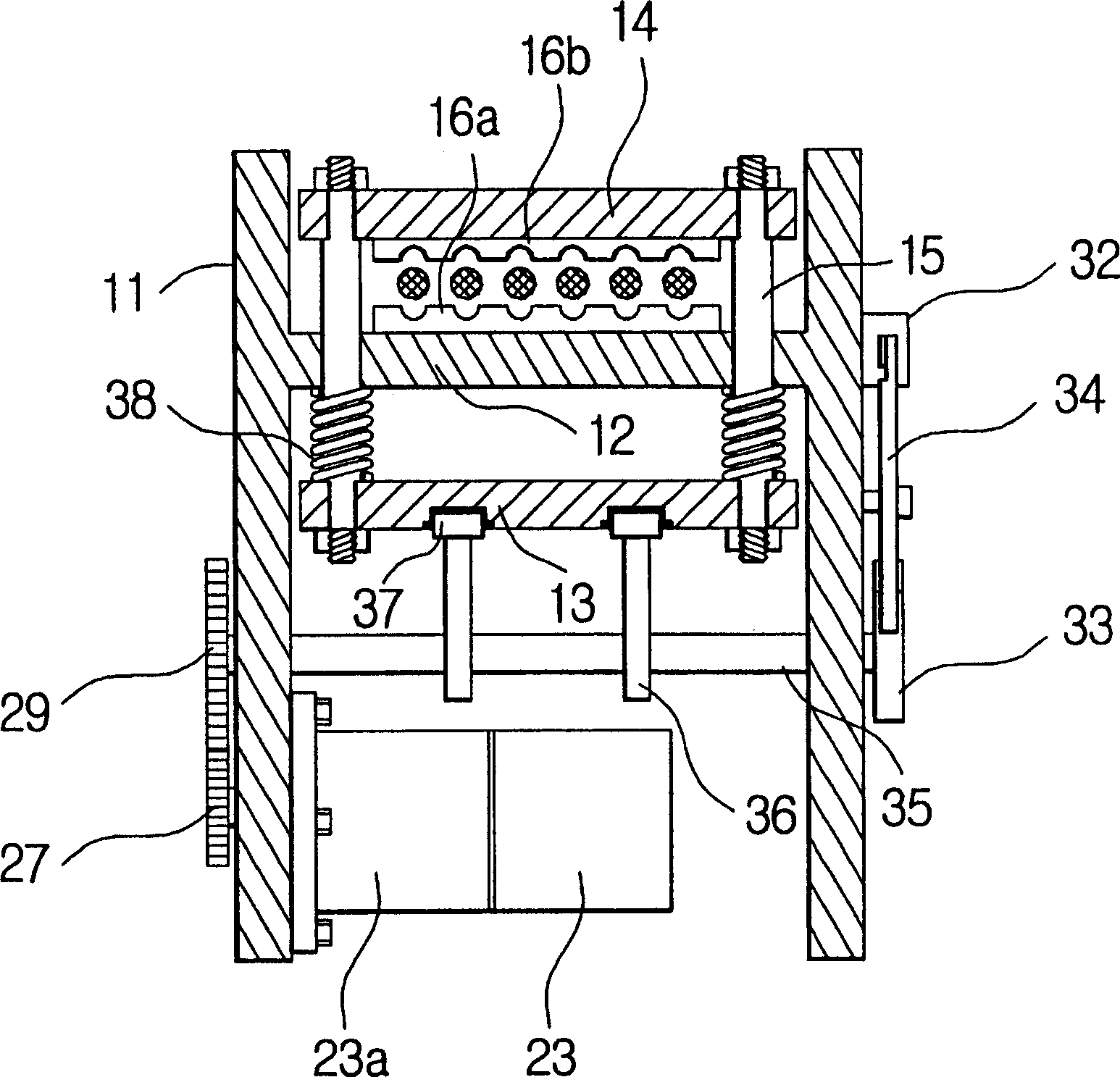

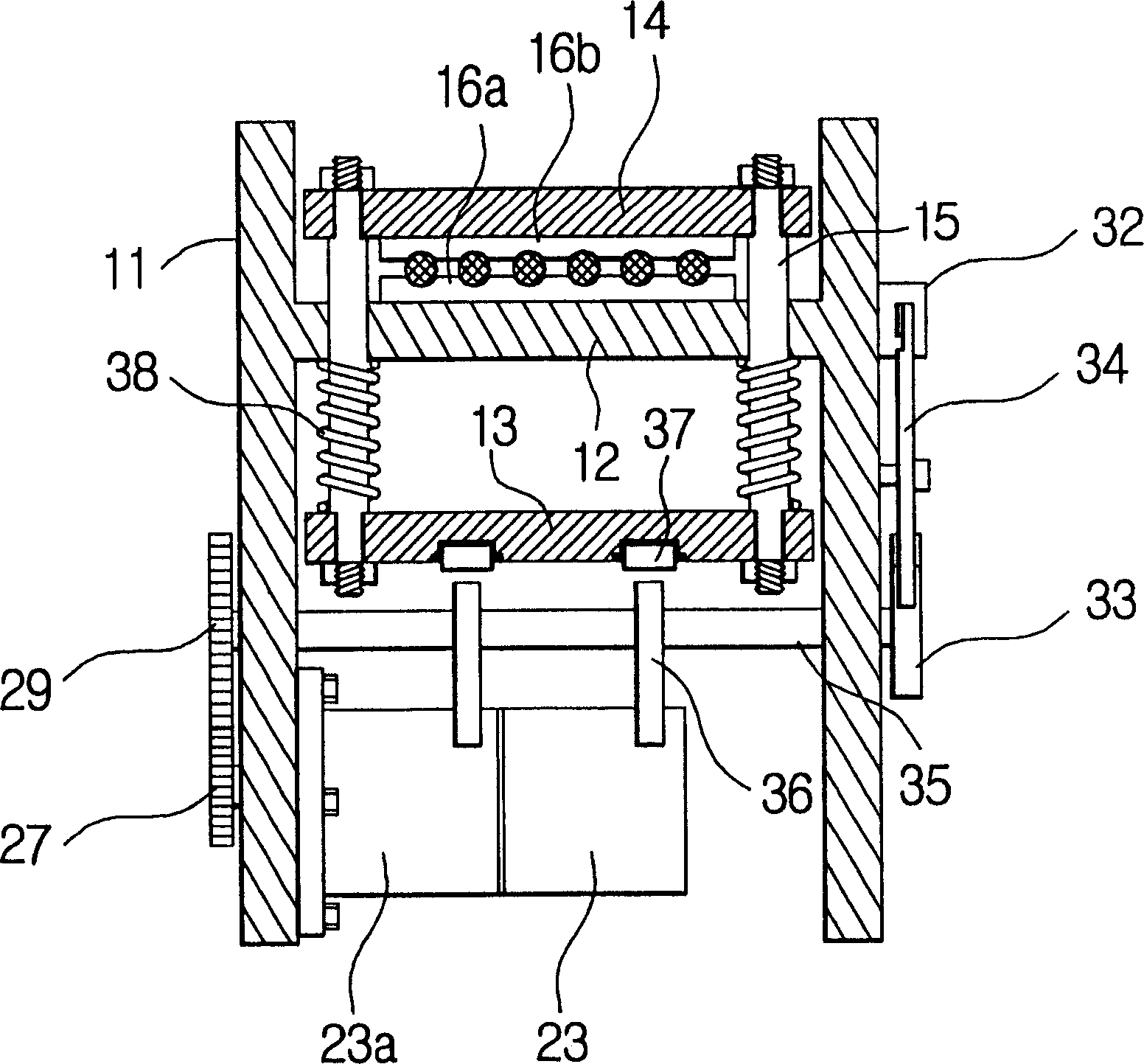

[0039] figure 1 It is a perspective view of the elevator wire rope brake according to the first embodiment of the present invention, figure 2 and image 3 is its floor plan. The structure of the present invention will be further described below in conjunction with the foregoing drawings.

[0040] The left and right boards 11 in the housing are located at both ends of the fixing board 12 and vertically integrated with the fixing board 12 to form an "H"-shaped frame.

[0041] The guide shaft 15 passes through the aforementioned fixed plate and can carry out sliding movement; the movable plate 13 and the movable plate 14 are respectively fixed on the two ends of the aforementioned guide shaft 15; A compression spring 38 is sleeved on the guide shaft 15 to accumulate compression force when the movable plate 13 moves toward the fixed plate 12 .

[0042] Camshaft 35 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com