Apparatus for grinding of spinning cylinders

A cot and cot technology, which is applied in the field of grinding spinning cot cots, can solve the problems of not being able to provide calculation of grinding results, and achieve the effect of accurate measurement results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

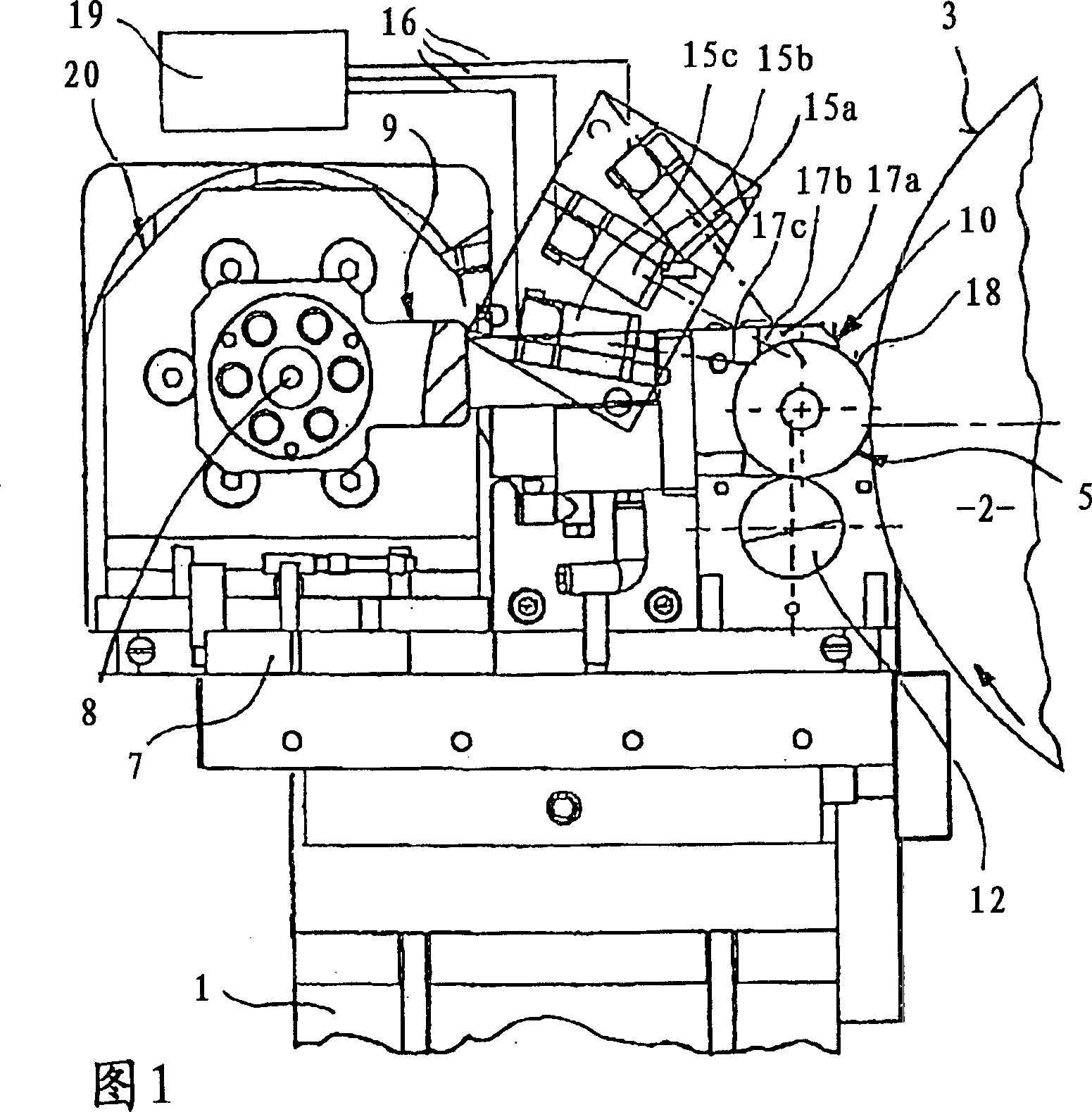

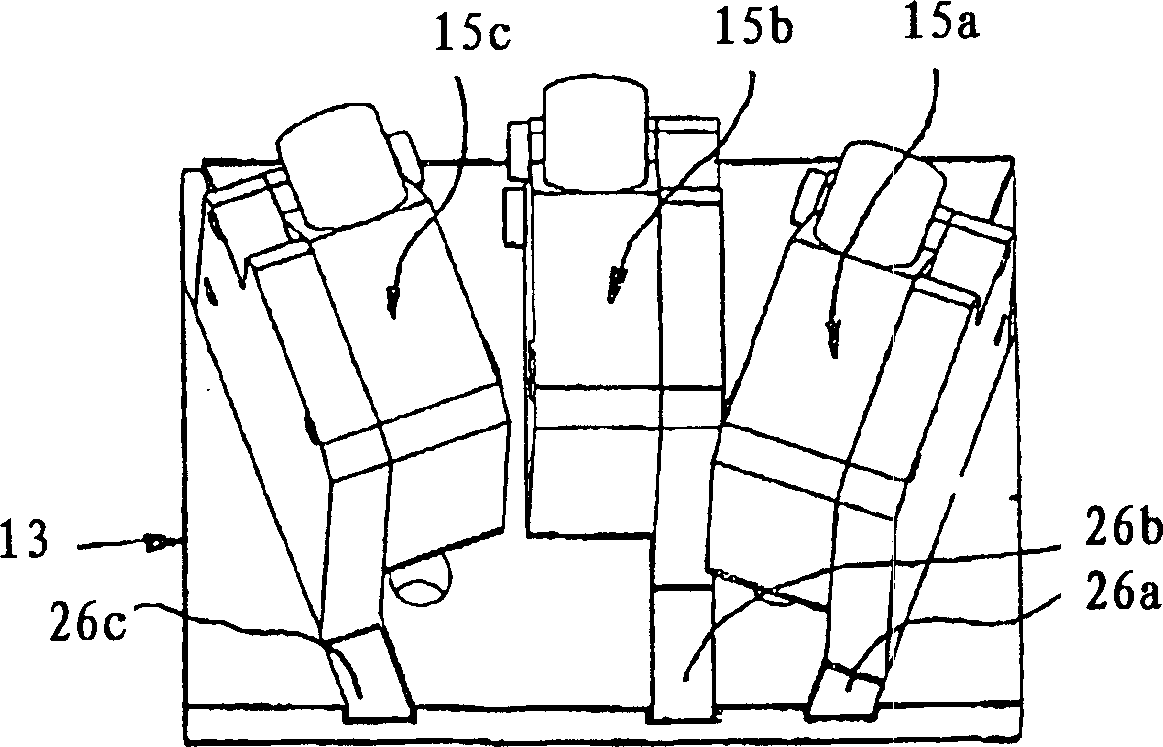

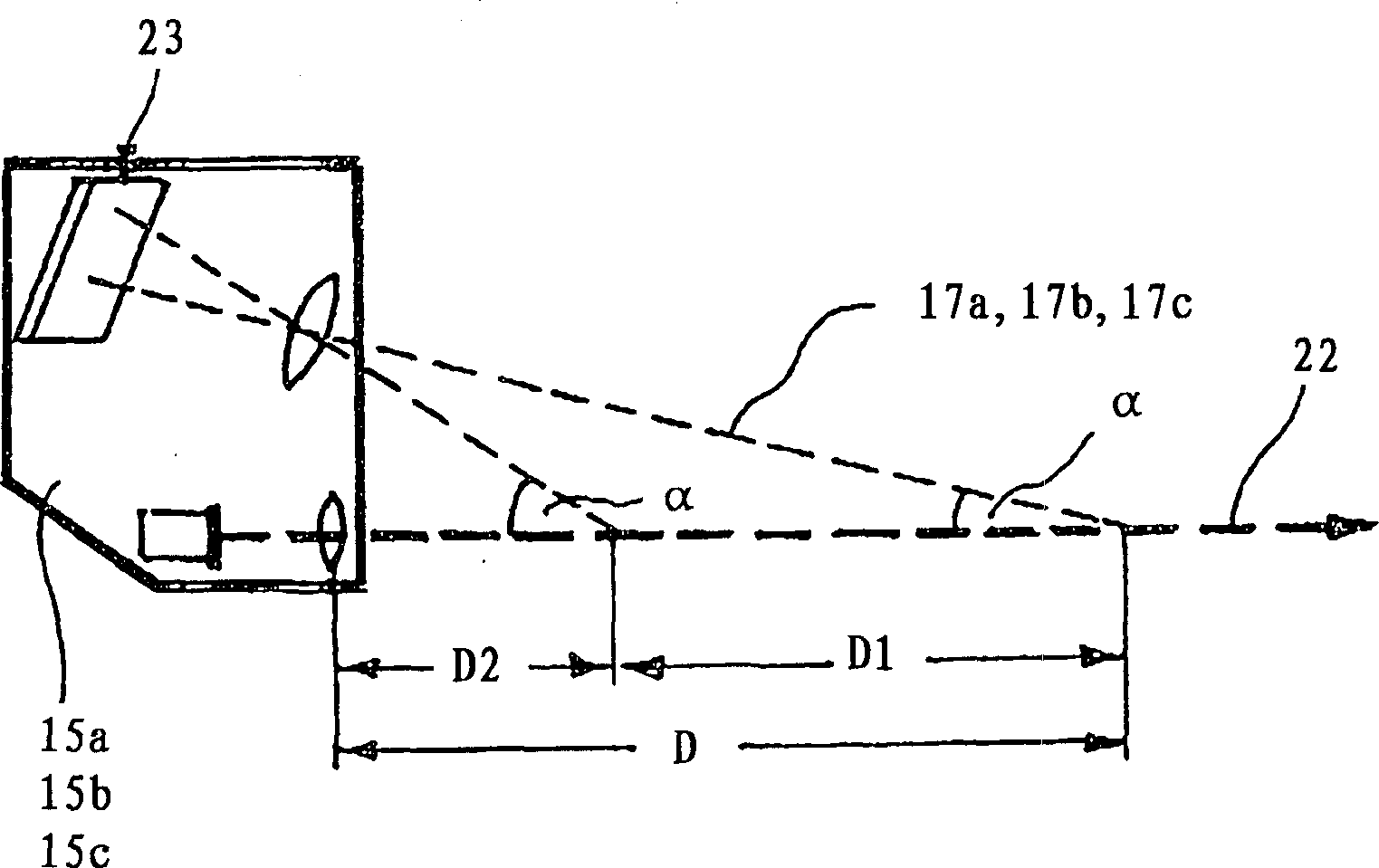

[0024] FIG. 1 shows in a very simplified diagram a part of a grinding machine for grinding the cots of spinning tops. This grinding machine is mainly used in spinning work. During spinning, the cots of the spinning cots act as transport rollers for guiding the textile fibers; in this respect, the cots are subject to a great deal of wear and therefore require frequent regrinding. From the outset, the diameter of the cots of the spinning cots is oversized so that they can be reground several times.

[0025] To this end, FIG. 1 shows a frame 1 of a grinding machine with a grinding roller 2 which is also mounted on the frame 1 and driven by a drive motor. The peripheral surface of this grinding roll 2 provides a grinding surface 3 for grinding the cots of the spinning tops, which are indicated by reference numeral 5 in the figures. For grinding the cots 5 of the spinning cots, a slide 7 is mounted on the frame 1, the slide 7 can move horizontally, that is to say essentially in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com