Dumping method for producing garbage dumping gas by using special garbage filling units

A technology of landfill gas and landfill units, applied in the direction of solid waste removal, etc., can solve the problems of increased construction cost of landfill gas collection facilities, difficulties in achieving breakthroughs in landfill gas collection rate, and increased construction density of gas collection facilities. Achieve stable water quality, reduce environmental load, and reduce environmental load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

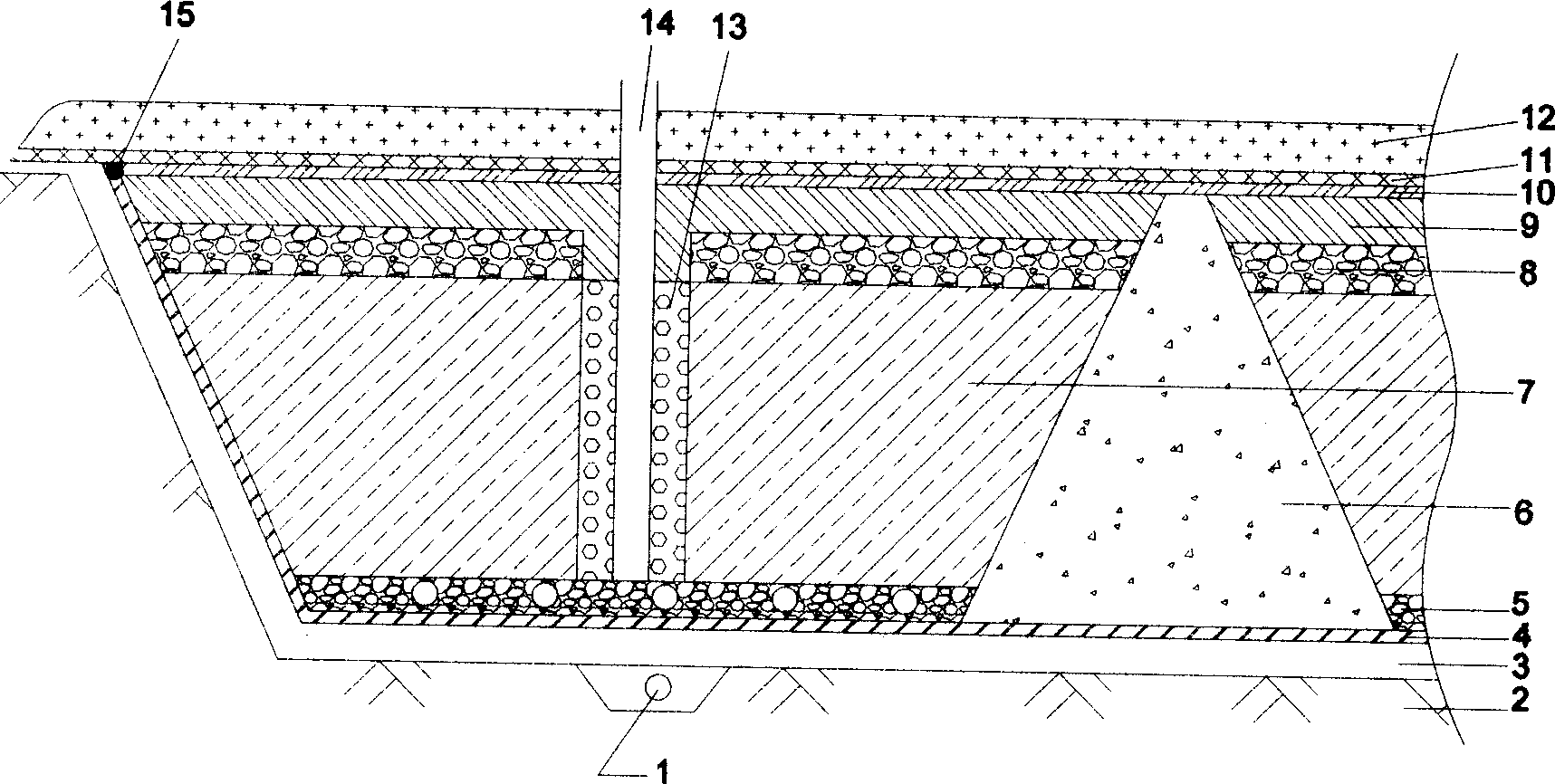

[0040] The daily processing capacity of a certain landfill is 500t / d, and the service life is 20 years; after calculating according to the composition of treated waste, terrain conditions and rainfall conditions, the maximum annual leachate production of this landfill is 108,000 cubic meters, according to the following Calculated by the formula: the total landfill capacity of the gas production unit (V 1 ) is 29589m 3 , rounded to 30000m 3 .

[0041]

[0042] Taking the average landfill depth of the gas production unit as 3m, the total landfill area of the gas production unit area of the landfill should be about 10000m 2 ; The landfill capacity of a single gas production unit is 3000m 3 , The average landfill depth of the gas production unit is 3m, and the landfill area of a single gas production unit is about 1000m 2 , a total of 10 units.

[0043] During the construction of the landfill, first, according to the construction specification requirements of the san...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com