Organic light emitting display

A technology of light-emitting display and organic light-emitting layer, which is applied in the field of organic light-emitting display devices, can solve problems such as deterioration of light-emitting characteristics and reduced lifespan, and achieve the effects of suppressing the reduction of light-emitting efficiency, prolonging lifespan, and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

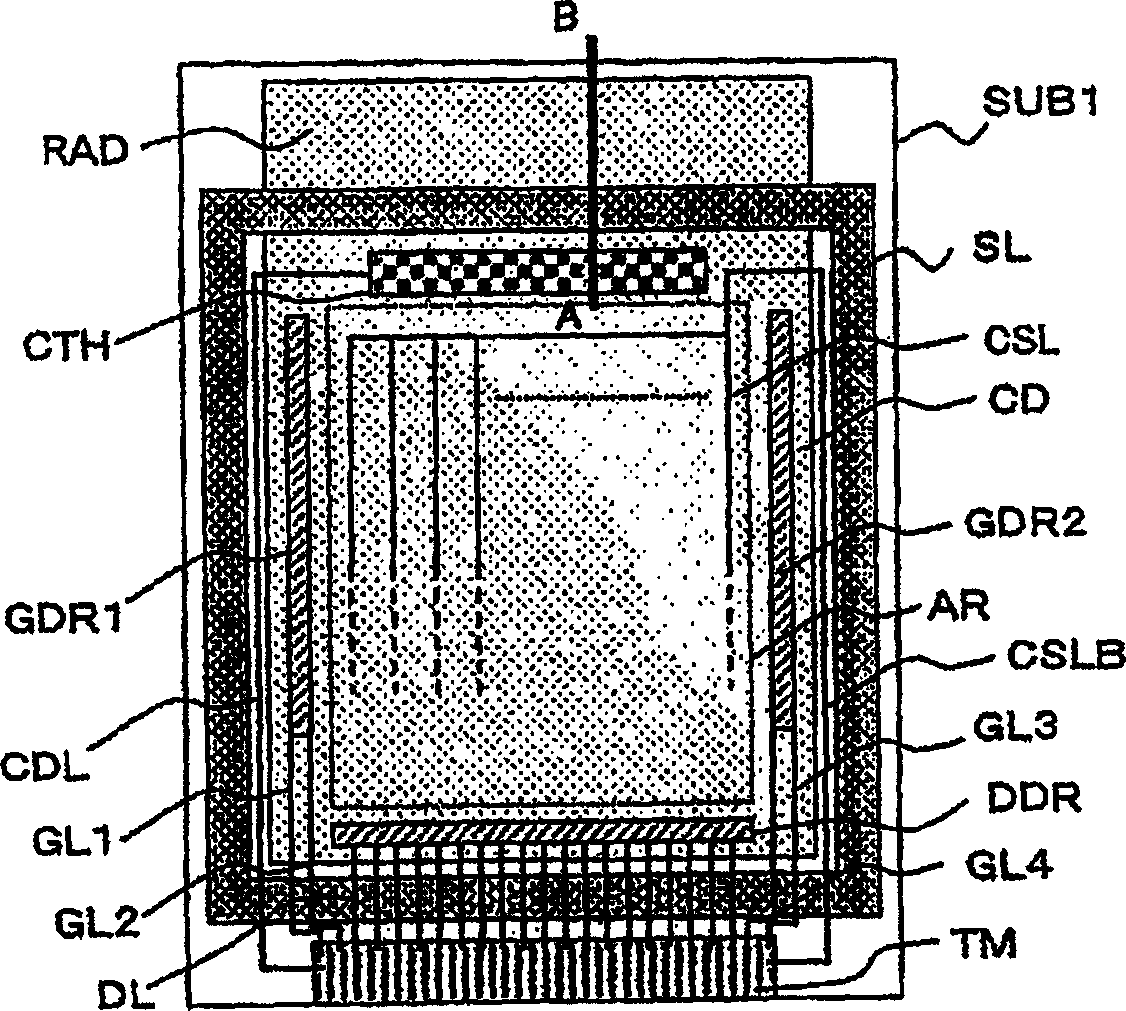

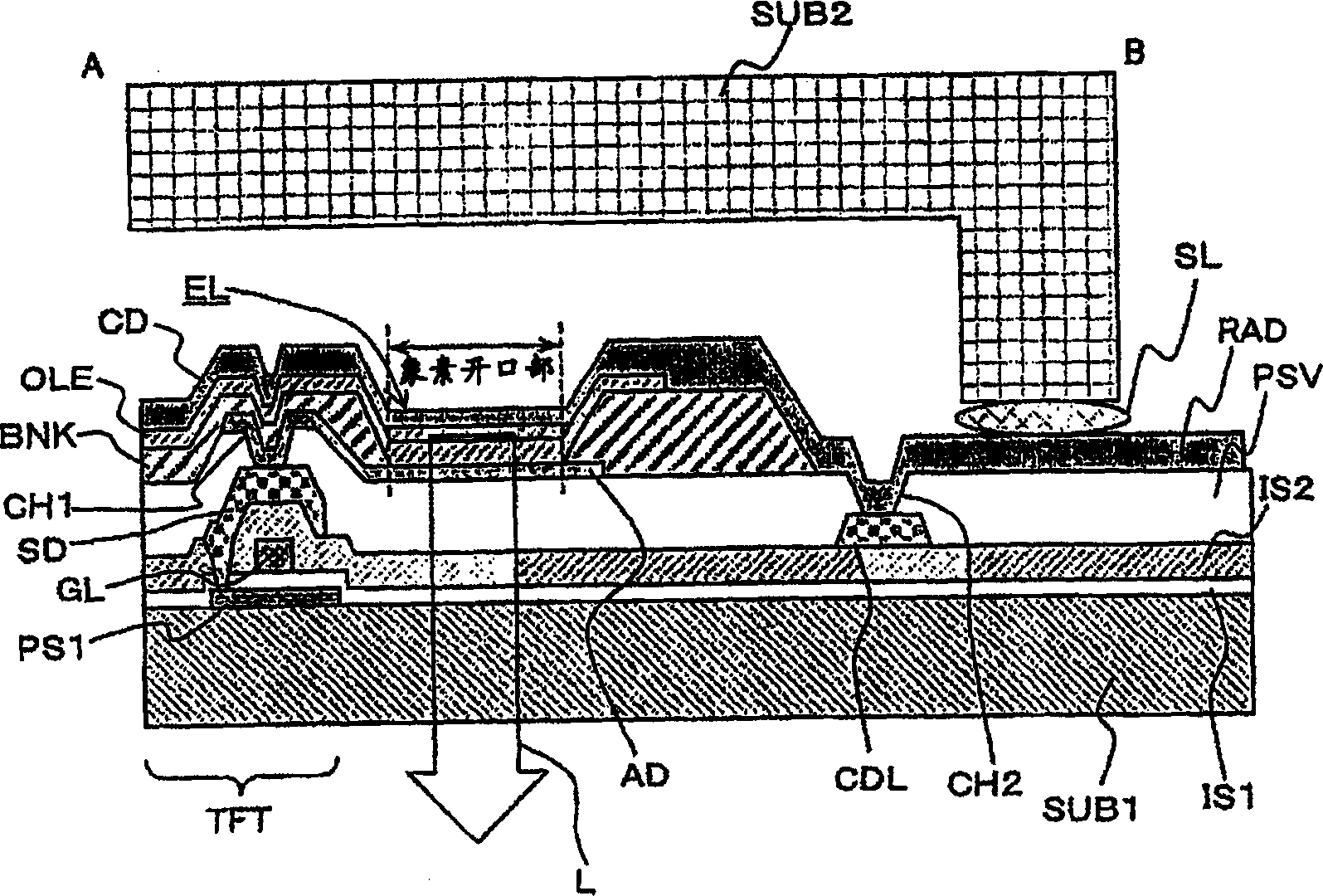

[0039] Figure 1A and Figure 1B It is a diagram schematically showing an active-matrix organic light-emitting display device having the structure of Example 1 of the organic light-emitting display device of the present invention. in, Figure 1A It is a top view showing the main part of the overall structure; Figure 1B is in Figure 1A An enlarged cross-sectional view near a pixel cut by line A-B. with the above Figure 5A , 5B The same reference numerals are attached to the same parts, and description thereof will be omitted.

[0040] Figure 1A , 1B In the organic light-emitting display device shown, the end of the cathode CD is extended to the outside of the sealing area sealed by the sealing material SL at the end of the main substrate SUB 1, so that it is integrally formed on the passivation layer PSV on the same surface. The heat sink RAD is made of the same aluminum material as the cathode CD, which is, for example, made of aluminum or a metal material containi...

Embodiment 2

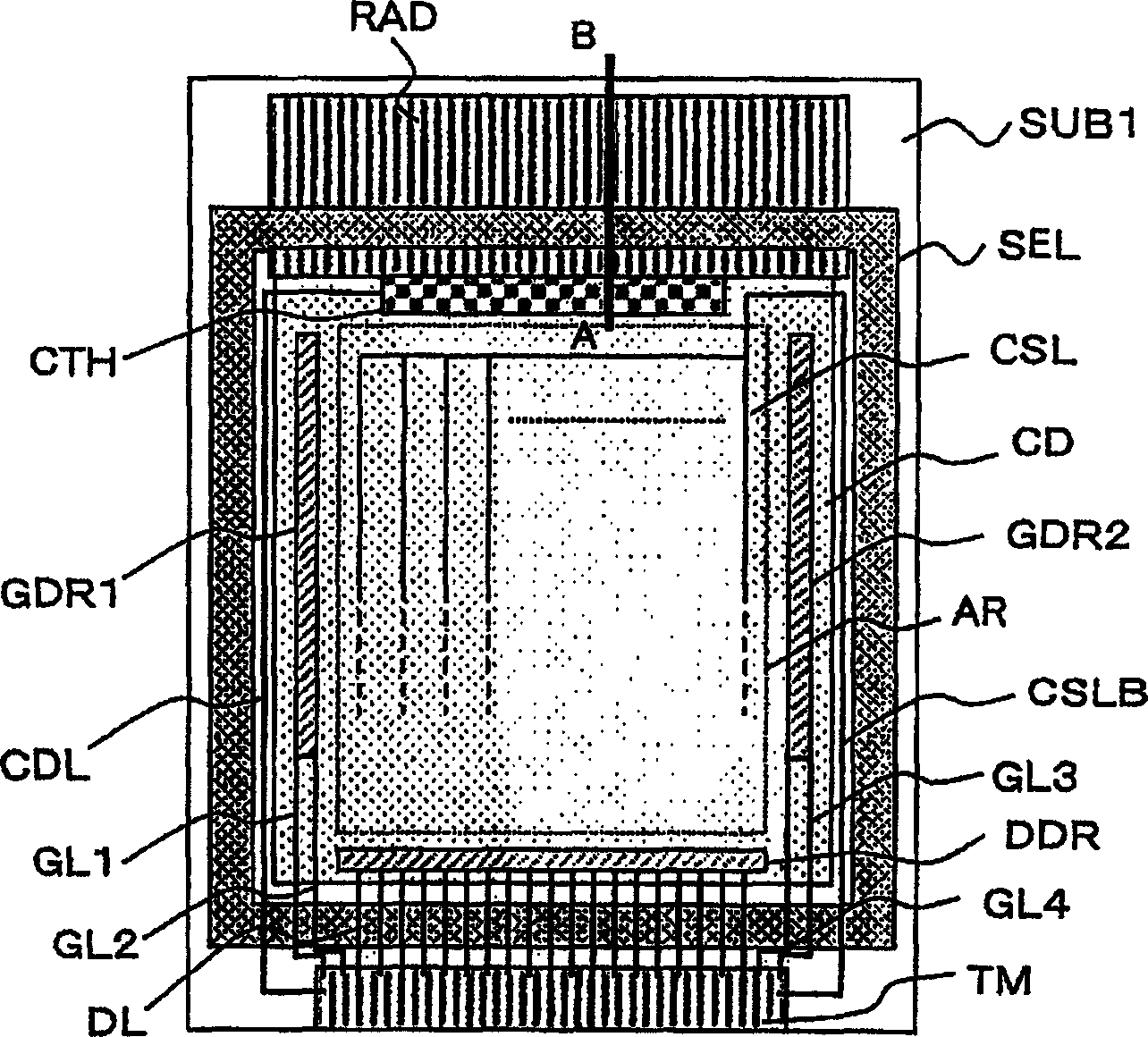

[0044] Figure 2A and Figure 2B It is a diagram schematically showing an active matrix organic light emitting display device having a structure of Example 2 of the organic light emitting display device of the present invention. in, Figure 2A It is a top view showing the main part of the overall structure; Figure 2B is in Figure 2A An enlarged cross-sectional view near a pixel cut by line A-B. with the above Figure 5A , 5B The same reference numerals are attached to the same parts, and description thereof will be omitted.

[0045] Figure 2A , 2B In the organic light emitting display device shown, a part of the cathode wiring CDL made of aluminum formed between the interlayer insulating film IS2 of the main substrate SUB1 and the passivation layer PSV is extended to the main substrate SUB1 on the interlayer insulating layer IS2. The heat dissipation portion RAD is integrally formed outside the sealing area of the substrate SUB1. The radiator RAD is integrally fo...

Embodiment 3

[0050] image 3 It is an enlarged cross-sectional view around one pixel of an active matrix organic light-emitting display device schematically showing the structure of Embodiment 3 of the organic light-emitting display device of the present invention. Figure 2A , 2B The same reference numerals are attached to the same parts, and description thereof will be omitted. image 3 In the organic light-emitting display device shown, the thermally conductive material HC is covered from the surface of the heat dissipation portion RAD drawn out of the sealing area of the main substrate SUB1 to the outer surface of the sealing glass substrate SUB2.

[0051] As a material of the thermally conductive material HC, for example, a metal film such as an aluminum film, a copper film, a magnesium film, or an alloy thereof can be used. These metal films can be formed by vapor deposition, sputtering, or CVD. In addition, other than the metal film, for example, a highly thermally conductive s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com