Organic inorganic composite photosensitive resin composition

A photosensitive resin and inorganic composite technology, applied in optics, optomechanical equipment, nonlinear optics, etc., can solve the problems of inability to spin coat dielectric constant, insufficient planarization, low dielectric constant, etc., and achieve high dielectric constant Characteristics, excellent performance, and the effect of improving dielectric properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0077] (Preparation of metal oxide dispersion)

[0078] Prepare Al separately 2 O 3 , Y 2 O 3 , La 2 O 3 , Ta 2 O 3 , TiO 2 , HfO 2 , ZrO 2 , (ZrO 2 ) 0.5 (SiO 2 ) 0.5 And (HfO 2 ) 0.5 (SiO 2 ) 0.5 Use a rotary ball mill to pulverize the powder, add propylene glycol monomethyl ether acetate to make the content of the metal oxide powder reach 5% to 50% by weight, add 500ppm to 20,000ppm of dispersant, and mix after wet mixing. Spray drying to prepare a metal oxide dispersion with a particle size of 50 nm to 200 nm.

Embodiment 2

[0080] (Preparation of acrylic copolymer)

[0081] 10 parts by weight of 2,2-azobis(2,4-dimethylvaleronitrile), 200 parts by weight of propylene glycol monomethyl ether acetate, 20 parts by weight of methacrylic acid, and 35 parts by weight of glycidyl methacrylate , 15 parts by weight of methyl methacrylate and 30 parts by weight of styrene were added to a flask with a cooling tube and a stirrer, and then slowly stirred after nitrogen replacement. The temperature of the reaction liquid was raised to 62°C, and a polymer solution containing an acrylic copolymer was prepared while maintaining the temperature for 5 hours. The acrylic copolymer prepared above was added dropwise to 5000 parts by weight of hexane for precipitation. After filtration and separation, 200 parts by weight of propionate was added to it and heated to 30°C to obtain a solid concentration of 45 parts by weight. Parts of a polymer solution with a weight average molecular weight of 11,000. The weight average mo...

Embodiment 3

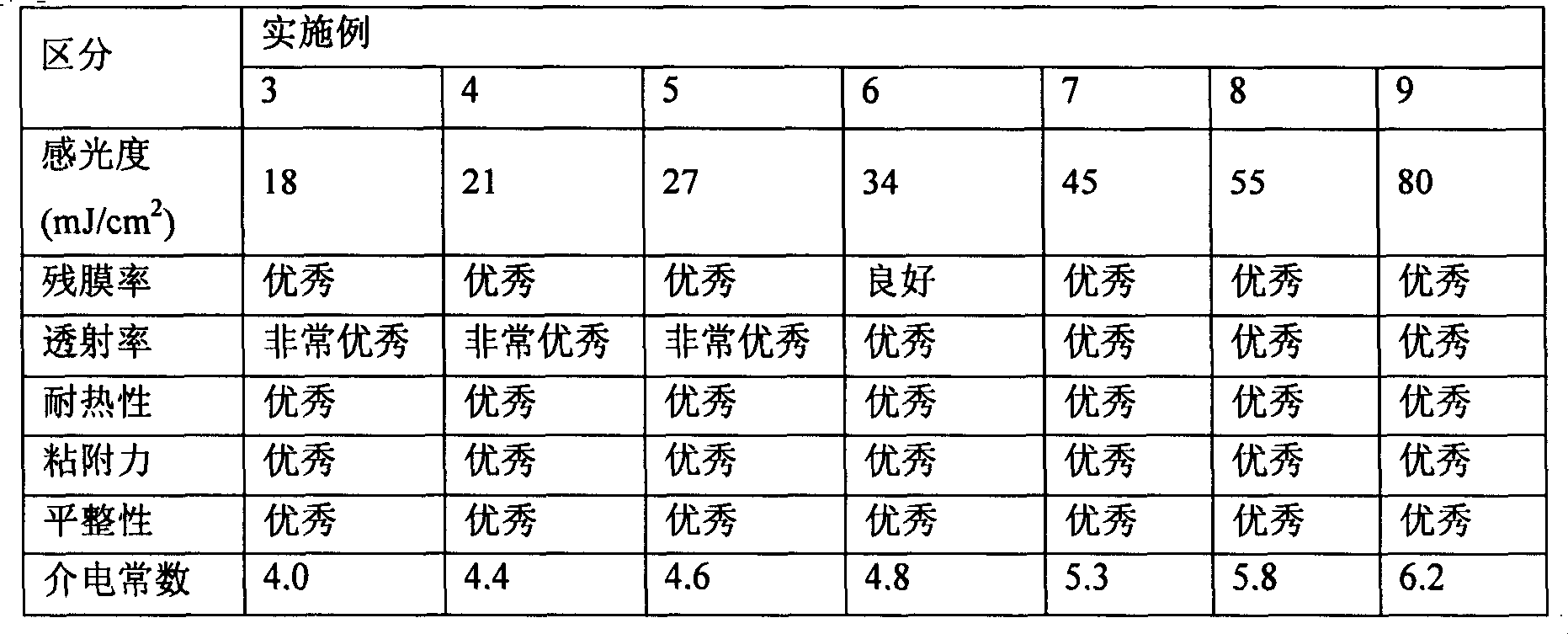

[0083] (Preparation of organic-inorganic composite photosensitive resin composition)

[0084] 100 parts by weight of the acrylic copolymer-containing polymer solution prepared in Example 2 above, 15 parts by weight of Irgacure 819 as a photoinitiator, and 5 parts by weight of 2-ethylhexyl-4-dimethylamino as a photosensitizer Benzoic acid ester and 5 parts by weight of n-butylacridone, 40 parts by weight of dipentaerythritol hexaacrylate as a multifunctional monomer, 10 parts by weight of trimethylolpropane triacrylate, and 1 part by weight as a silicon compound 2-(3,4-epoxycyclohexyl)ethyltrimethoxysilane and 2 parts by weight of F171 as a silicon-based surfactant were mixed. Diethylene glycol dimethyl ether was added to the above mixture and dissolved so that the concentration of the solid content reached 35% by weight.

[0085] The Al prepared in Example 1 2 O 3 The metal oxide dispersion and the organic photosensitive resin prepared above were mixed in a weight ratio of 5:95 to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com