Process for treating lighter cast shell surface and sticking sheet for lighter shell

A shell surface and treatment process technology, applied in the direction of combustion ignition, igniter with fuel, combustion method, etc., can solve the problems of color difference in electroplating, lack of overall sense, uneven and consistent wire drawing and electroplating wire path, etc., and achieve electroplating wire The road is neat and consistent, and the effect of electroplating color difference is consistent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

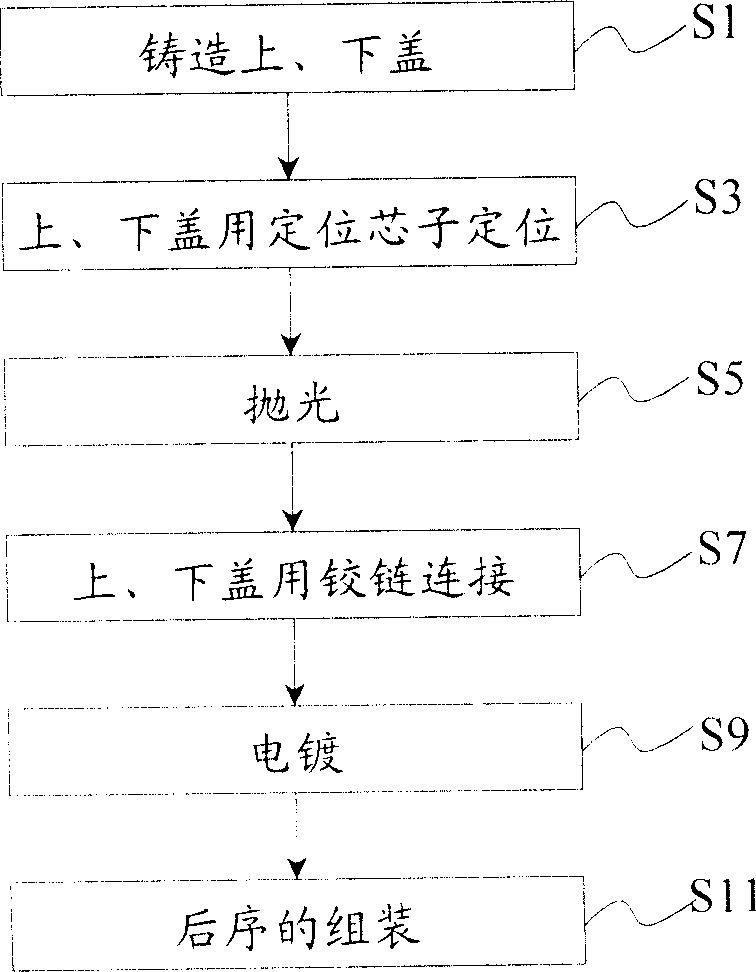

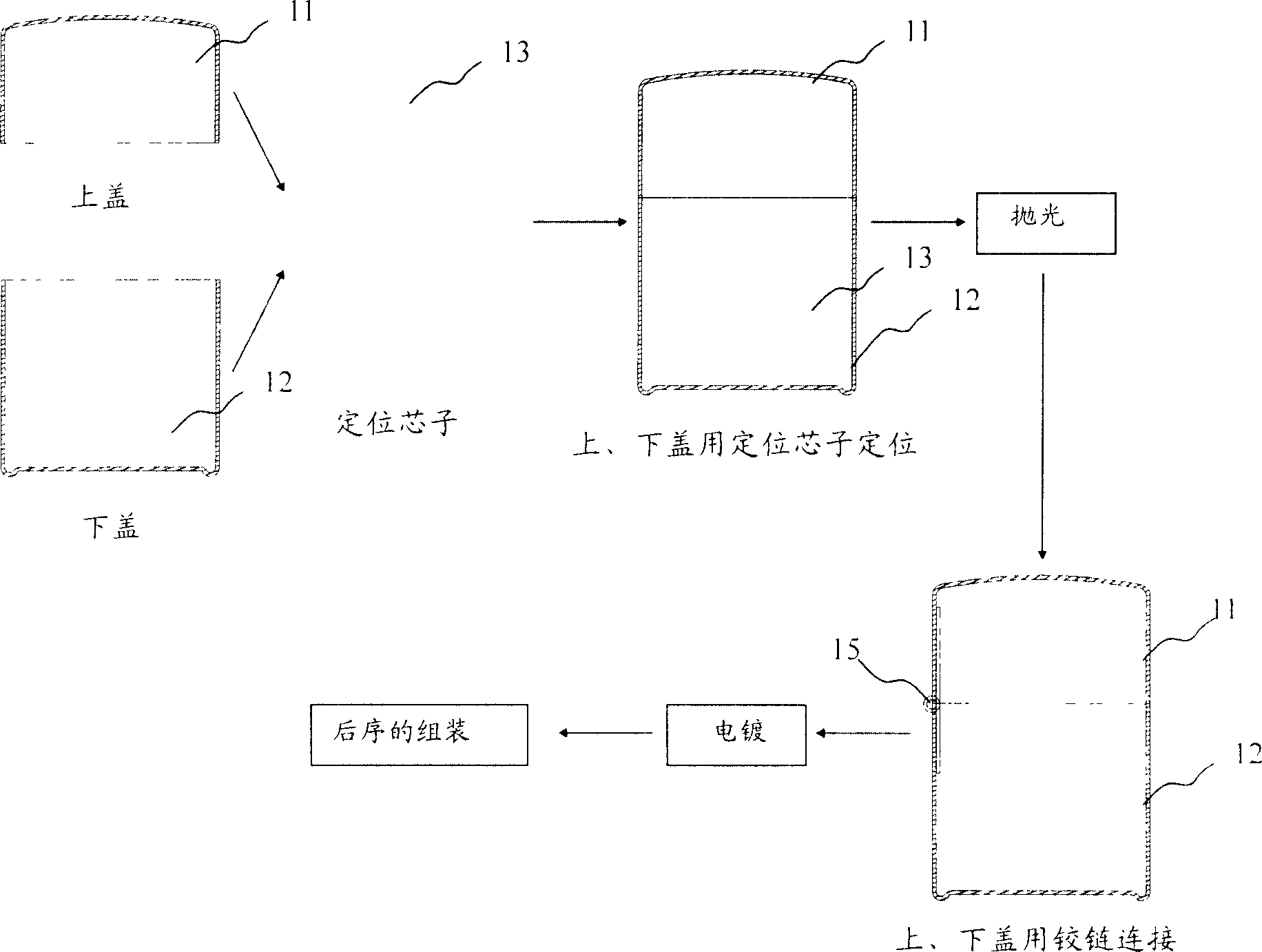

[0017] The surface treatment process of the cast shell of the lighter of the present invention will be described in detail below in conjunction with the accompanying drawings.

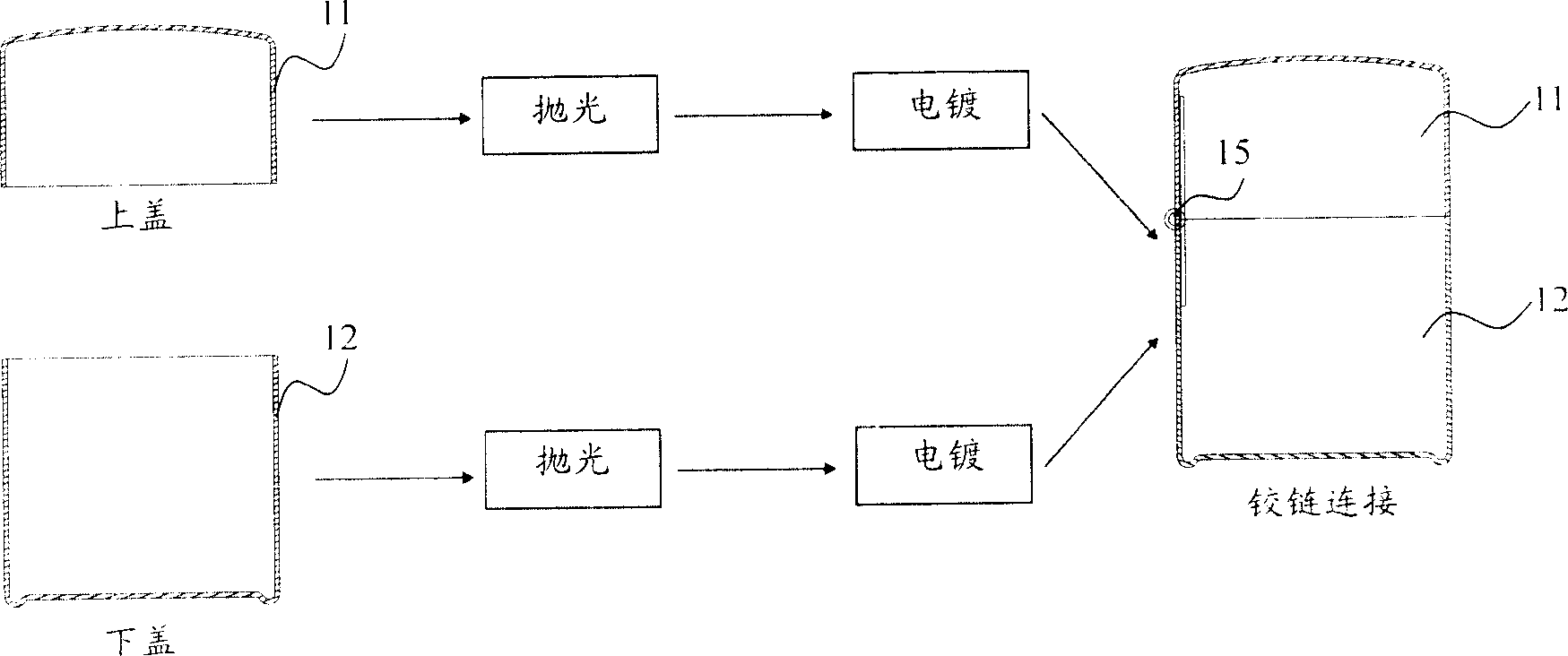

[0018] figure 2 Show the flow chart of upper and lower cover surface treatment process in lighter casting shell surface treatment process of the present invention, in conjunction with reference image 3 , which includes the following steps, and the sequence number of each step is represented by a combination of letters and numbers. In the figure,

[0019] S1: casting upper and lower covers. Usually the upper and lower covers 11, 12 are respectively cast from aluminum or aluminum alloy, and of course they can also be cast from other metals, such as copper or copper alloy.

[0020] S3: The upper and lower covers are positioned with positioning cores. Usually, the positioning core 13 is a housing tightly matched with the upper and lower covers, such as a housing made of metal casting, or a housing for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com