Process for preparing organic electroluminescence material bis (8-hydroxy quinoline lithium sodium)

A technology of lithium sodium hydroxyquinoline and electroluminescent materials, which is applied in the direction of luminescent materials, chemical instruments and methods, and can solve problems such as influence and broadening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

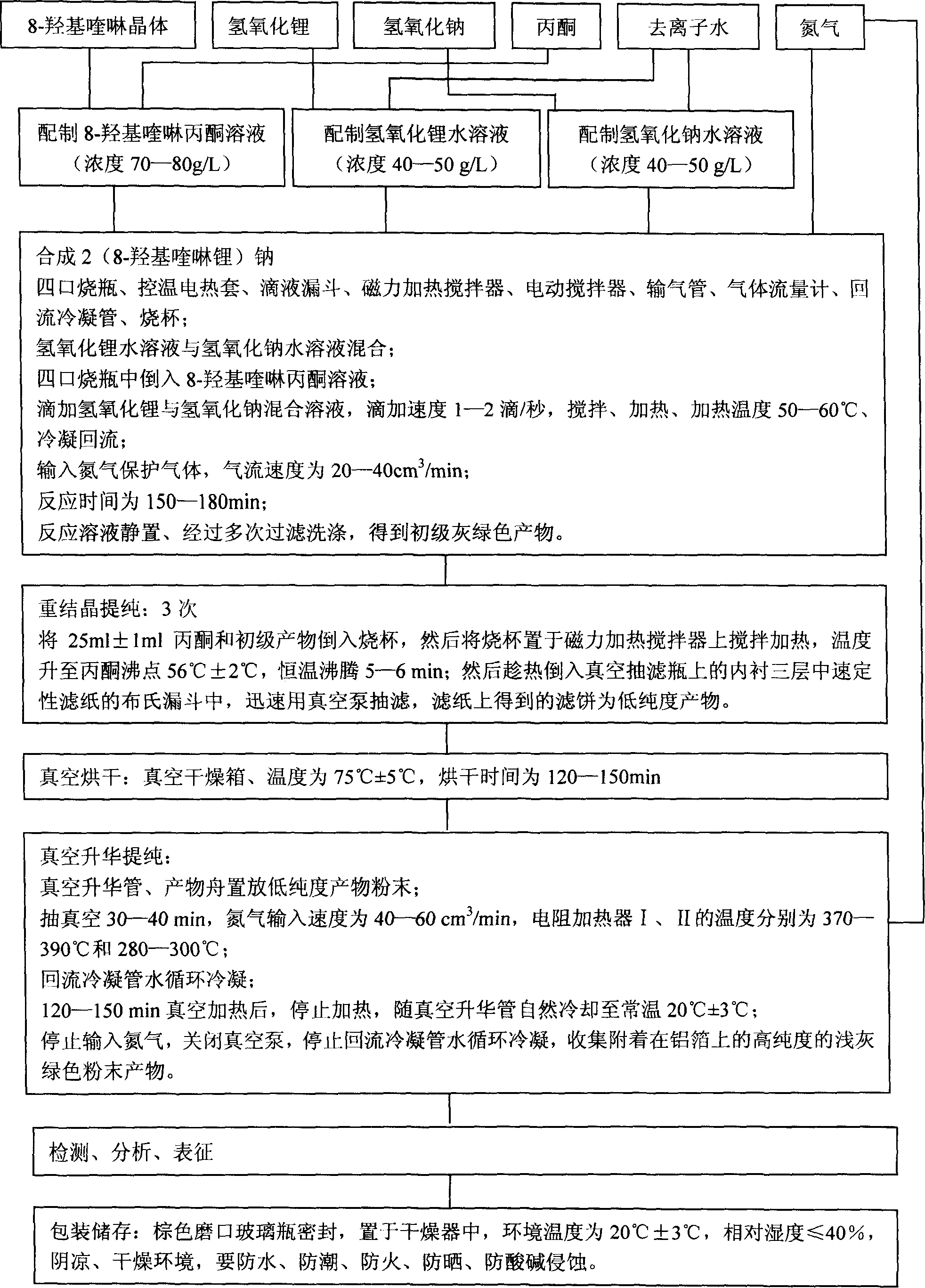

Method used

Image

Examples

Embodiment 1

[0107] All preparation equipment and experimental instruments are in quasi-working condition;

[0108] Select chemical raw materials and conduct purity control;

[0109] Preparation of 8-hydroxyquinoline acetone solution:

[0110] 1.59g of 8-hydroxyquinoline crystals and 25ml of acetone were placed in a beaker, stirred with a magnetic stirrer, mixed and dissolved to form an 8-hydroxyquinoline acetone solution with a concentration of 70-80g / L;

[0111] To prepare lithium hydroxide solution:

[0112] Put 0.23g of lithium hydroxide and 5ml of deionized water in a beaker, stir with a magnetic stirrer, mix and dissolve to form a lithium hydroxide aqueous solution with a concentration of 40-50g / L;

[0113] To prepare sodium hydroxide solution:

[0114] Put 0.22g of sodium hydroxide and 5ml of deionized water in a beaker, stir with a magnetic stirrer, mix and dissolve to form a sodium hydroxide aqueous solution with a concentration of 40-50g / L;

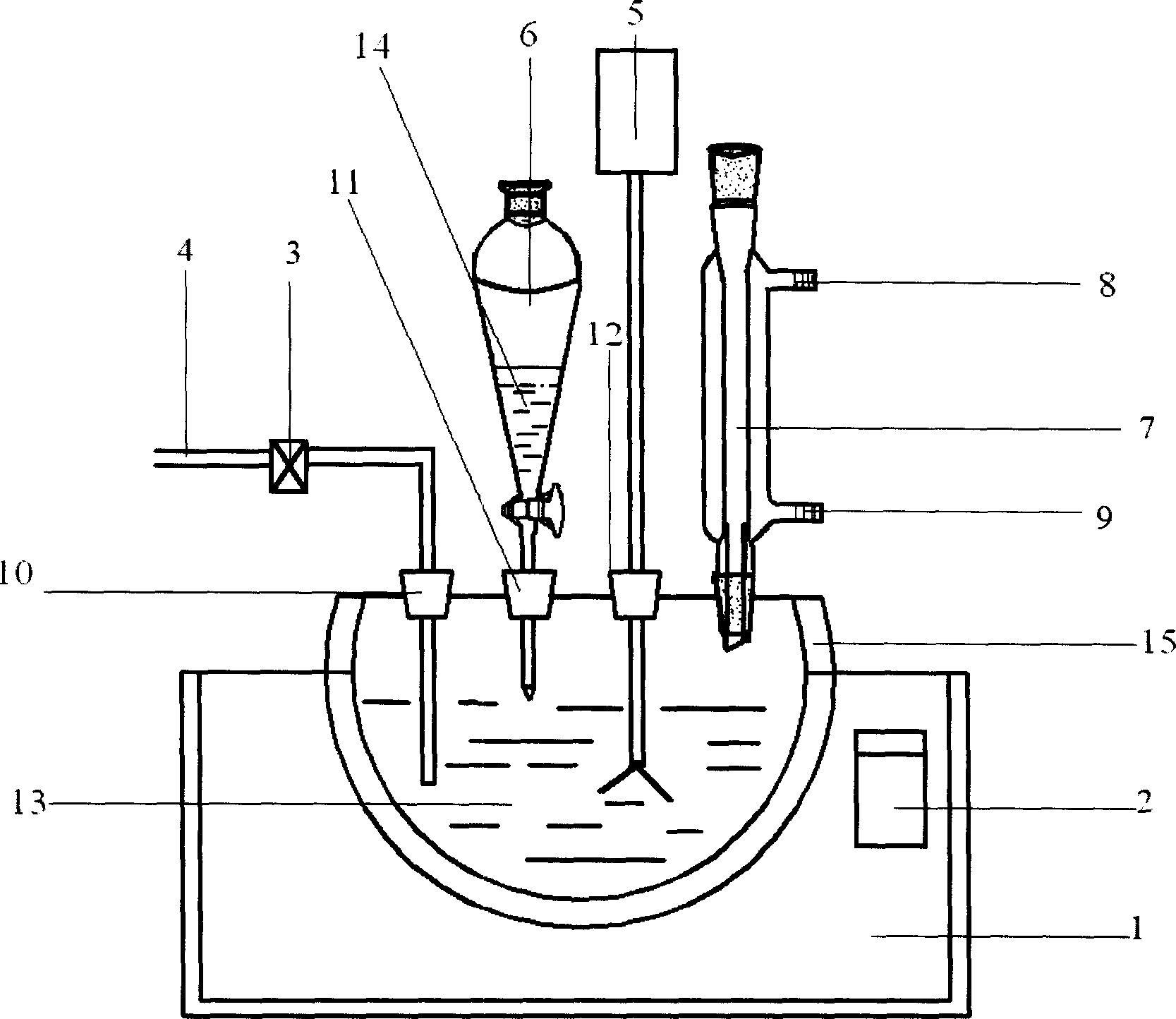

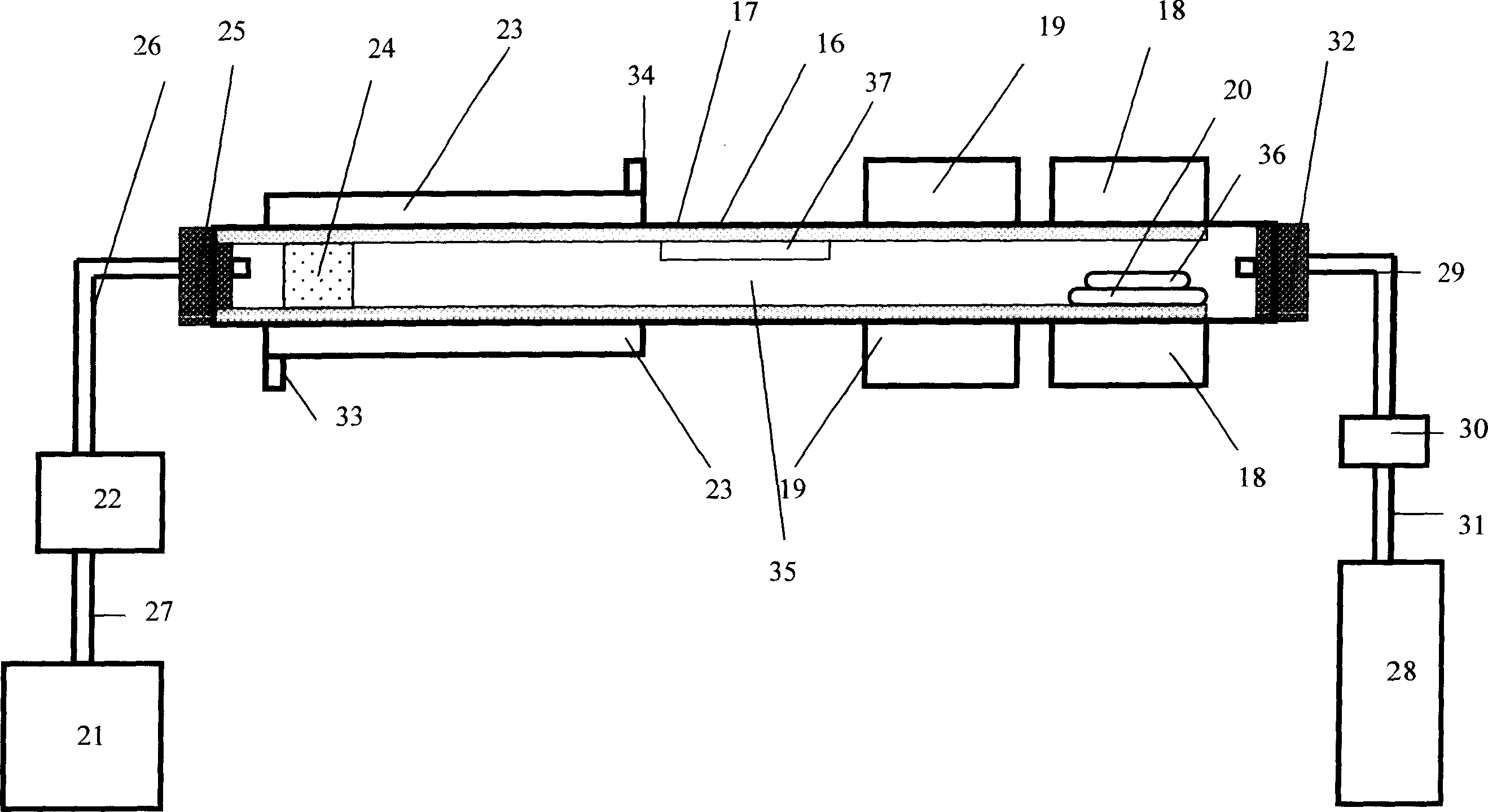

[0115] Synthesis of 2(8-hydroxyqu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com