Method for treating SO2 in coal firing smoke by red mud

A coal-burning flue gas, SO2 technology, applied in the direction of separation methods, chemical instruments and methods, separation of dispersed particles, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

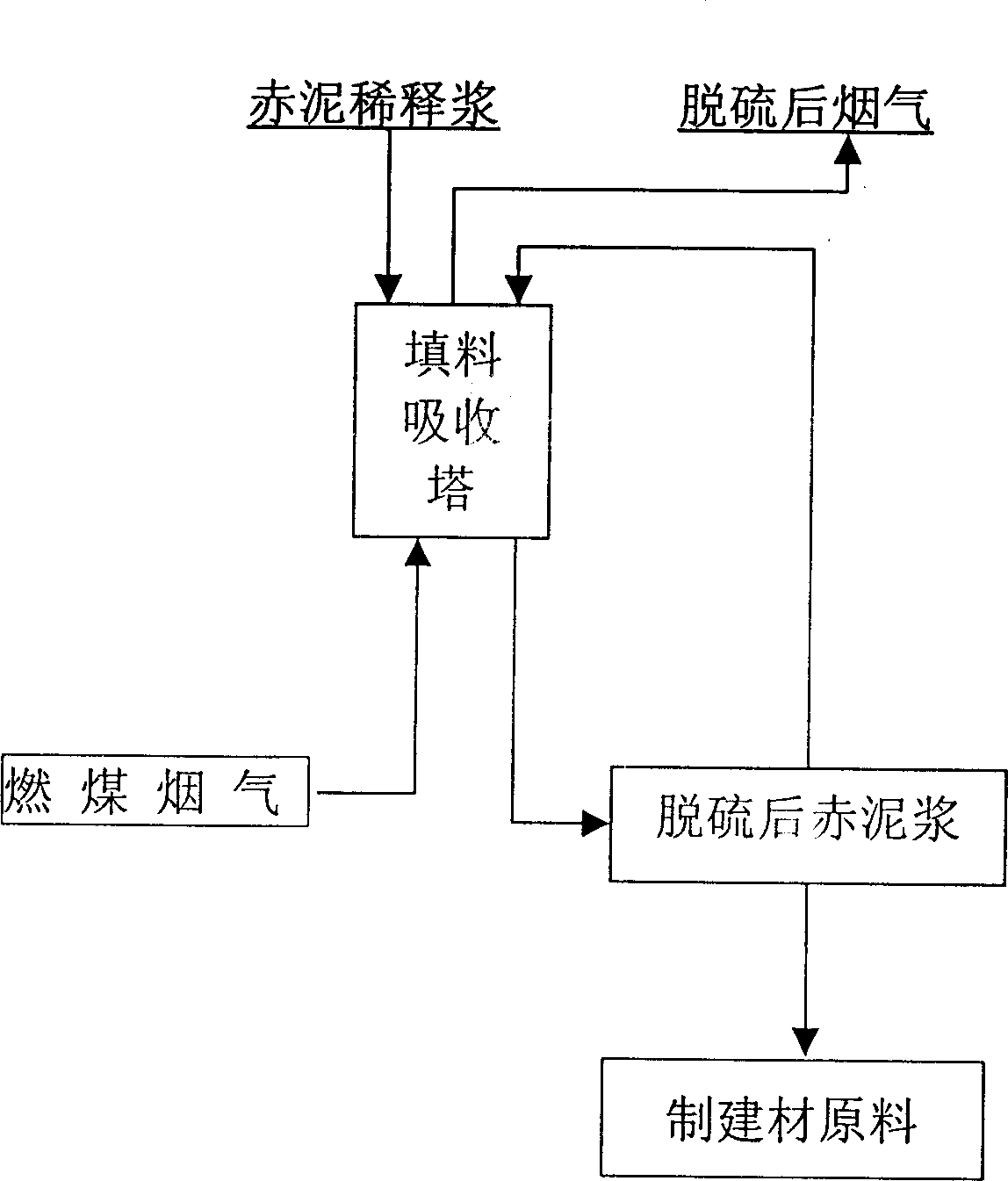

Image

Examples

Embodiment 1

[0021] The red mud is prepared with water to form a red mud dilution slurry with a liquid-solid ratio L / S (weight ratio) of 10:1, and it is sprayed in the packed absorption tower to contact with the coal-fired flue gas countercurrently to absorb and absorb the coal-fired flue gas SO in 2 . SO in coal combustion flue gas before absorption 2 The concentration is 980mg / m 3 , SO in coal-fired flue gas after absorption 2 The concentration is 190mg / m 3 , the desulfurization rate is 80.6%. When the PH value of the red mud slurry is close to neutral after being recycled and absorbed, the red mud slurry is drained and separated, and the separated desulfurized red mud meets the standards for raw materials for building materials.

Embodiment 2

[0023] The red mud is prepared with water to form a red mud dilution slurry with a liquid-solid ratio L / S of 12:1, and it is sprayed in the packed absorption tower to contact with the coal-fired flue gas countercurrently to absorb and absorb the coal-fired flue gas. SO 2 . SO in coal combustion flue gas before absorption 2 The concentration is 920mg / m 3 , SO in coal-fired flue gas after absorption 2 The concentration is 180mg / m 3 , the desulfurization rate is 80.4%. When the PH value of the red mud slurry is neutral after being recycled and absorbed, the red mud slurry is discharged, settled and separated, and the separated desulfurized red mud meets the standards for being used as a raw material for building materials.

Embodiment 3

[0025] The red mud is prepared with water to form a red mud dilution slurry with a liquid-solid ratio L / S of 15:1, and it is sprayed in the packing absorption tower to contact with the coal-fired flue gas countercurrently to absorb and absorb the coal-fired flue gas. SO 2 . SO in coal combustion flue gas before absorption 2 The concentration is 950mg / m 3 , SO in coal-fired flue gas after absorption 2 The concentration is 160mg / m 3 , the desulfurization rate is 84.2%. When the PH value of the red mud slurry is neutral after being recycled and absorbed, the red mud slurry is discharged, settled and separated, and the separated desulfurized red mud meets the standards for being used as a raw material for building materials.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com