Conductive contact holder, conductive contact unit and process for producing conductive contact holder

A retainer and conductivity technology, which is applied in the direction of electrical components, manufacturing measuring instruments, single semiconductor device testing, etc., can solve problems such as difficult to control the size of the retainer substrate 101, and achieve the effect of suppressing warpage and position deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

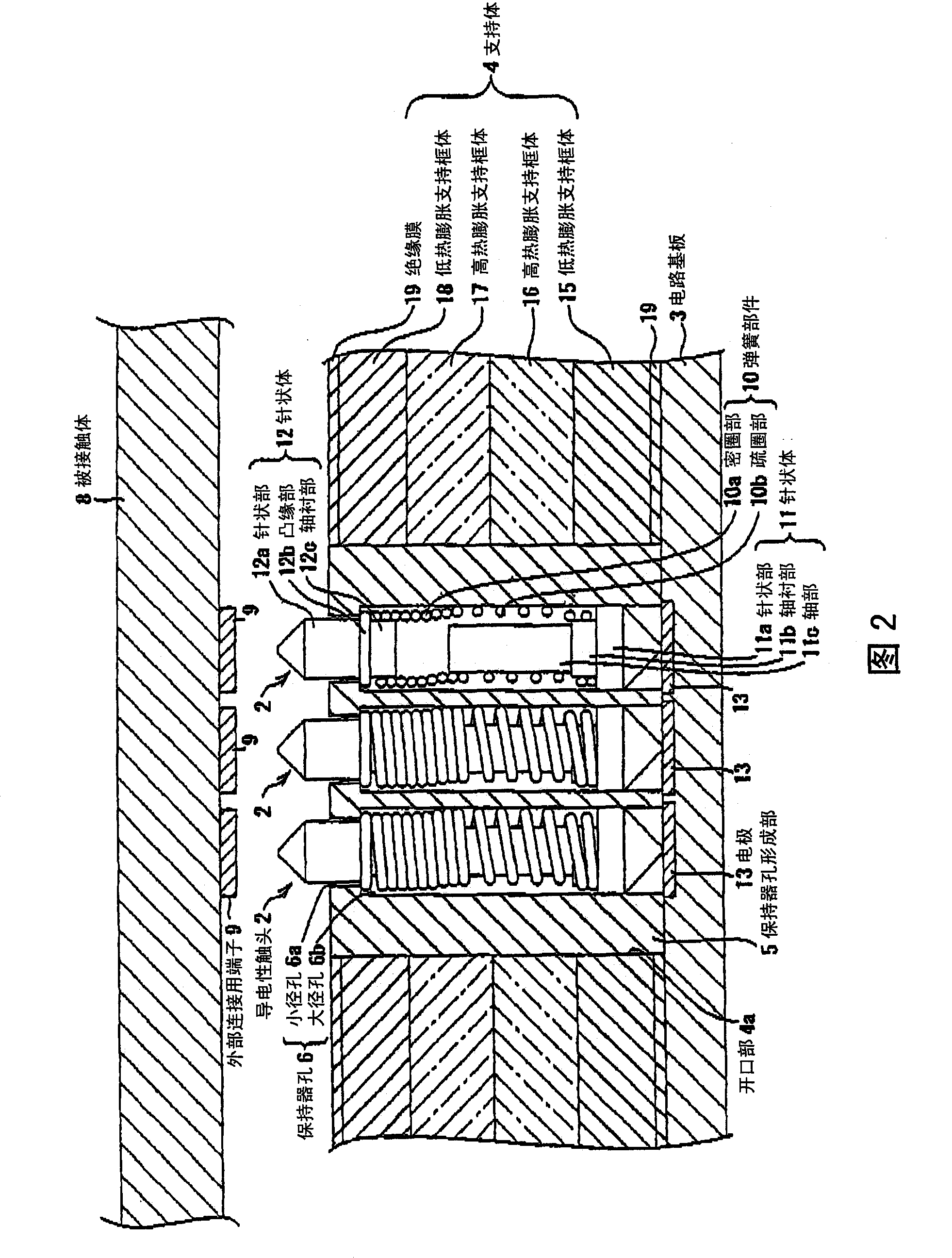

[0046] Hereinafter, the best mode for implementing a conductive contact unit to which the conductive contact holder of the present invention is applied (hereinafter referred to as "embodiment") will be described in detail with reference to the drawings. In addition, the drawings are schematic diagrams. It should be noted that the relationship between the thickness and width of each part, the ratio of the thickness of each part, etc. are different from the actual situation. Of course, the relationship or ratio of mutual dimensions is also included in the drawings. different parts.

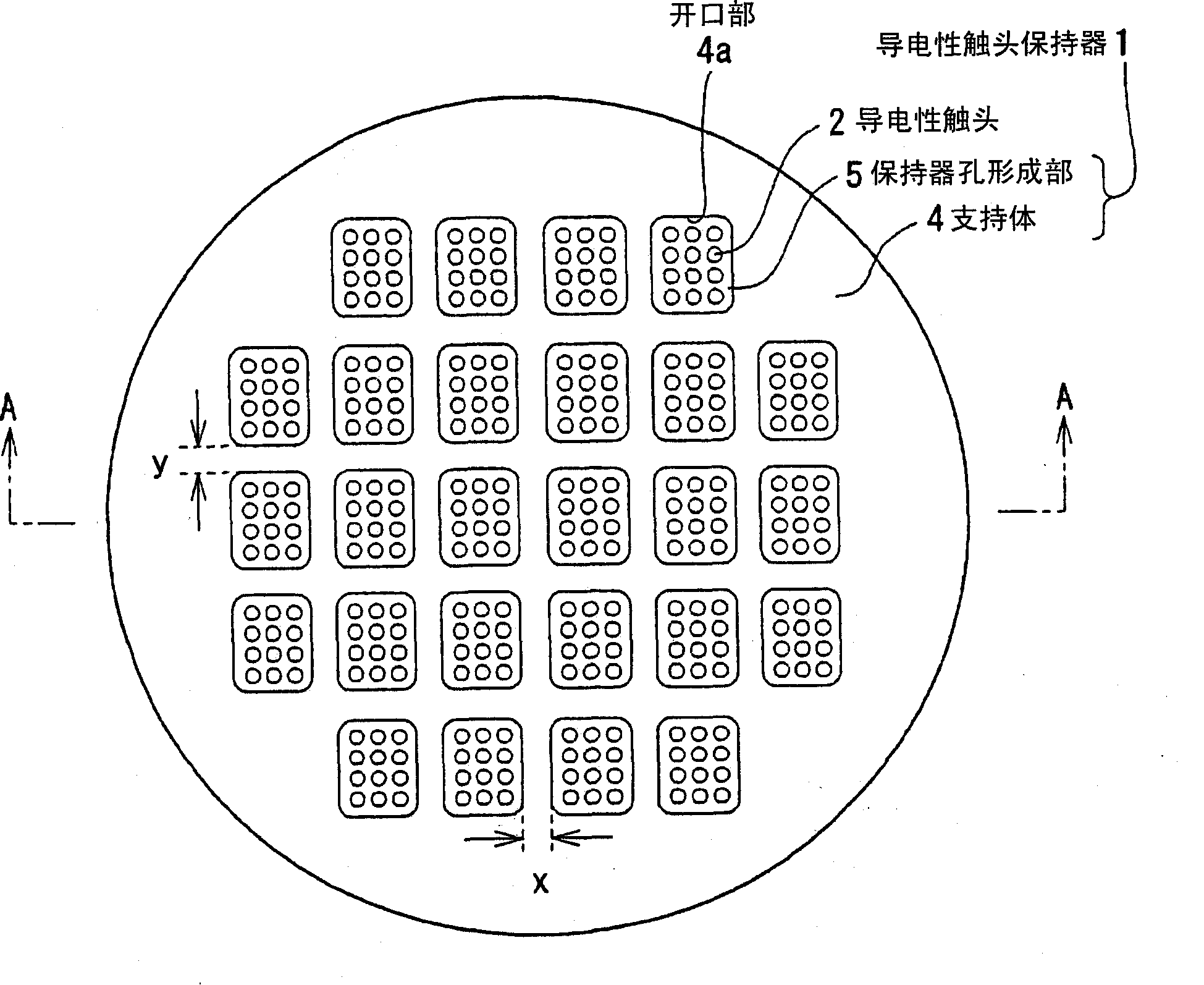

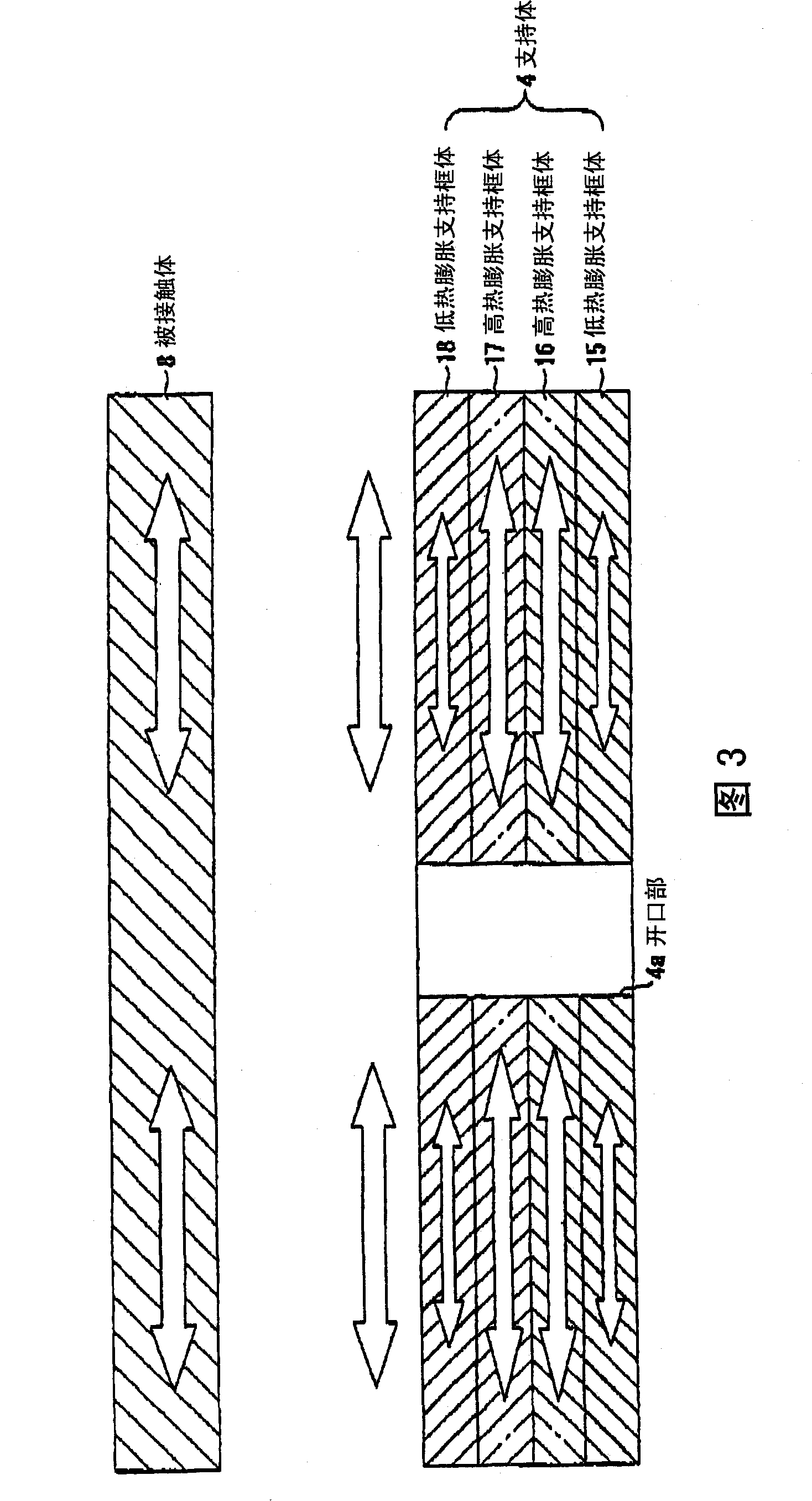

[0047] The conductive contact unit of the present embodiment has a structure that includes a support that supports a frame body with a high thermal expansion having a higher linear expansion coefficient than the contacted body, and has a lower linear expansion than the contacted body. Coefficients of low thermal expansion support frame stacks are obtained. figure 1 It is a plan view of the conduct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com