Calibrated tester of oximeter

A test device and oximeter technology, applied in the calibration of instruments, instruments, instrument parts, etc., can solve the problems of difficult permanent stable reference standards, differences in tissue blood oxygen content, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

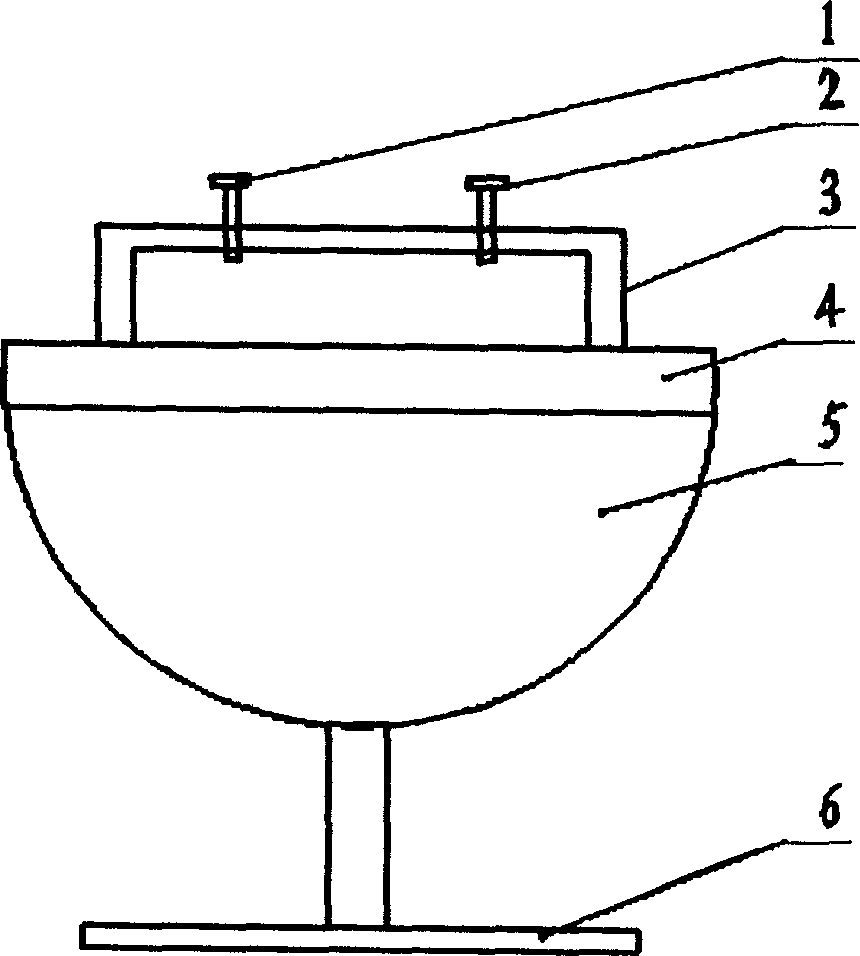

[0023] The oximeter calibration test device includes an integrating sphere 5, the bottom of which is connected to the base 6 to form a goblet shape. The integrating sphere 5 is a hemispherical shell with a diameter of 200 mm and a wall thickness of 2 mm processed from duralumin, and its inner surface is coated with Thickness is the polyester fluoroethylene material layer of 2 millimeters; The bottom disk diameter of base 6 is 120 millimeters, thickness 5 millimeters, and middle part connecting rod diameter is 15 millimeters, high 70 millimeters.

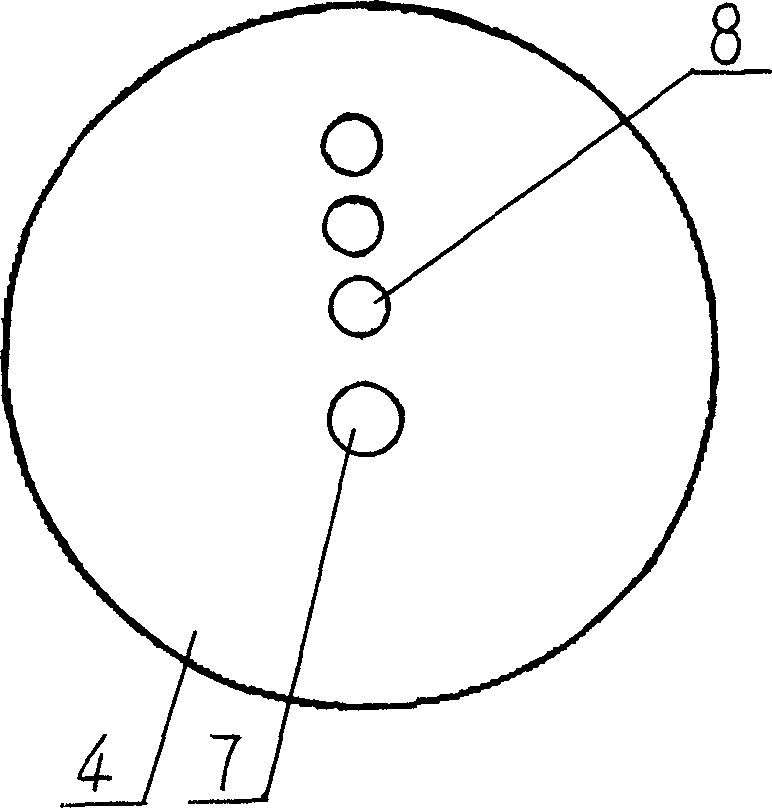

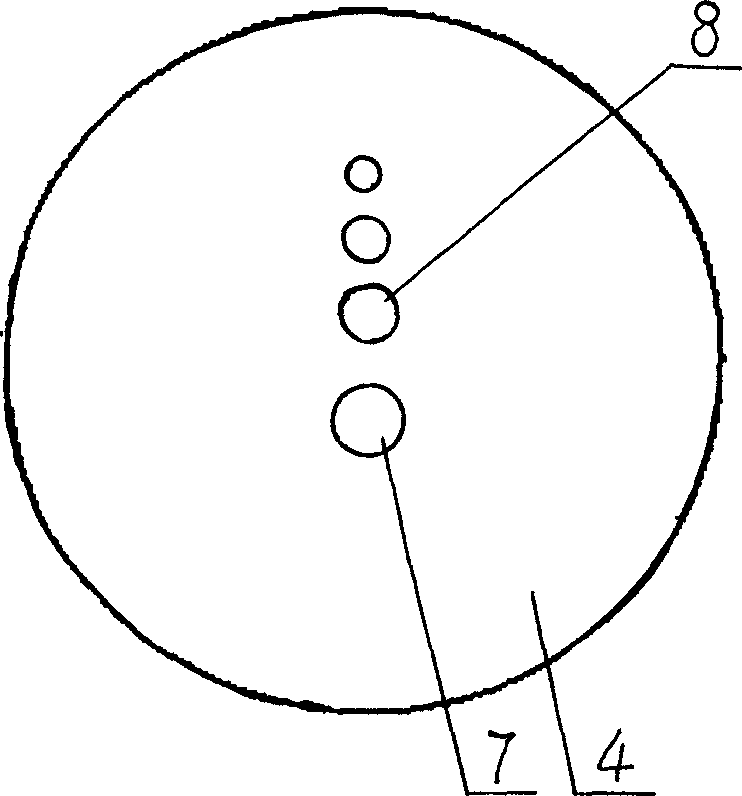

[0024] The upper opening of the integrating sphere 4 is a disc-shaped working platform 4, on the working platform 4, there are a transmitting hole 7 and three receiving holes 8 in sequence along the diameter direction; the transmitting hole diameter is 10 mm, and the diameter of the three receiving holes is equal to is 3mm. The center-to-center distance between the transmitting hole 7 and the adjacent receiving hole 8 is 20 mm, and t...

Embodiment 2

[0028] The diameter of the transmitting hole 7 is 12 millimeters, and the diameters of the three receiving holes 8 are respectively 5 millimeters, 1.65 millimeters, and 0.5 millimeters; the transmitting hole 7 is adjacent to the receiving hole 8 with a diameter of 5 millimeters, and the transmitting hole 7 is adjacent to the adjacent receiving hole 8 The distance between centers is 20 mm, and the distance between centers of adjacent receiving holes is 10 mm.

[0029] Others are with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com