Method for using special chelant for micro electronic

A chelating agent and microelectronics technology, applied in the field of microelectronics, can solve the problem that the content of metal ions cannot be effectively reduced, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

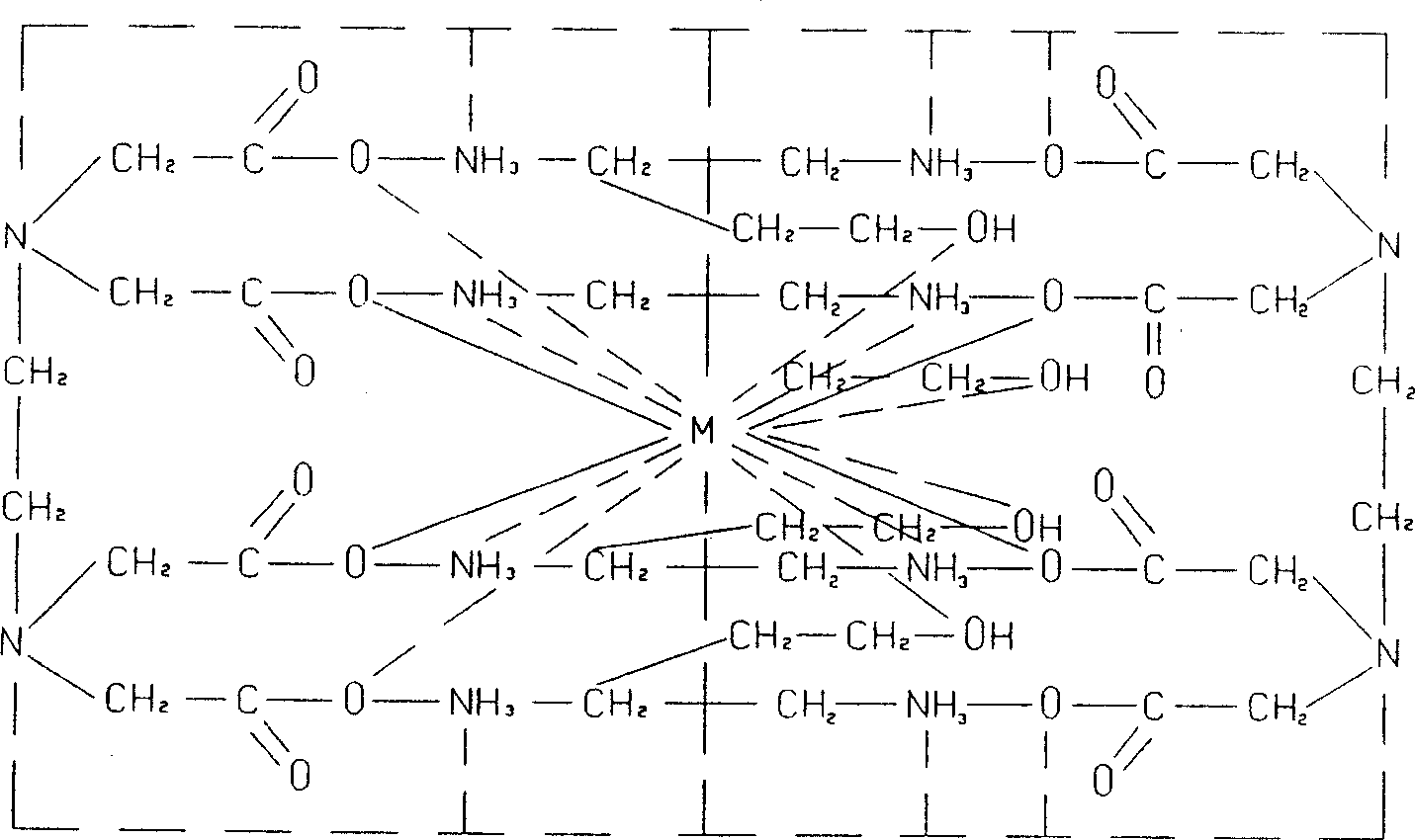

Image

Examples

Embodiment 1

[0024] Put the grinding disc into the polishing machine, add 0.1% microelectronic special chelating agent diethylenediaminetetraacetic acid tetrahydroxyethylethylenediamine salt in the common polishing liquid by volume percentage, the polishing liquid is alkaline, and the pH is 13. Then polish according to the conventional polishing method.

[0025] Then put the above-mentioned polishing sheet into the cleaning tank, add 0.1% of microelectronic special chelating agent diethylenediaminetetraacetic acid tetrahydroxyethylethylenediamine salt into the cleaning agent, and 1% of hydrogen peroxide as the oxidizing agent, and then follow the routine The cleaning method is used for cleaning to obtain a clean wafer.

Embodiment 2

[0027] Put the grinding piece into the polishing machine, the polishing liquid is acidic, and the pH value is 1, add 3% microelectronic special chelating agent diethylenediaminetetraacetic acid tetrahydroxyethylethylenediamine salt in the above polishing liquid by volume percentage , and 1% hydrogen peroxide as an oxidizing agent, and then polished according to conventional polishing methods.

[0028] Then put the above-mentioned polishing sheet into the cleaning tank, add 3% of microelectronics special chelating agent diethylenediaminetetraacetic acid tetrahydroxyethylethylenediamine salt into the cleaning agent, and 3% of hydrogen peroxide as the oxidizing agent, and then follow the routine The cleaning method is used for cleaning to obtain a clean wafer.

Embodiment 3

[0030] Put the grinding disc into the polishing machine, the polishing liquid is acidic, and the pH value is 3, add 1% microelectronic special chelating agent diethylenediaminetetraacetic acid tetrahydroxyethylethylenediamine salt in the above polishing liquid by volume percentage , and 2% hydrogen peroxide as an oxidizing agent, and then polished according to conventional polishing methods.

[0031] Then put the above-mentioned polishing sheet into the cleaning tank, add 1% special chelating agent diethylenediaminetetraacetic acid tetrahydroxyethylethylenediamine salt in the cleaning agent, and 5% hydrogen peroxide as the oxidizing agent, and then follow the routine The cleaning method is used for cleaning to obtain a clean wafer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com