Colour filter for liquid crystal display device

A color filter and liquid crystal display technology, applied in the field of color filters, can solve the problems of abnormal liquid crystal alignment, unable to ensure the thickness uniformity of the display area, and reduce the flatness of the substrate film layer, so as to improve the flatness and avoid the liquid crystal Abnormal alignment, improve the effect of frame light leakage problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

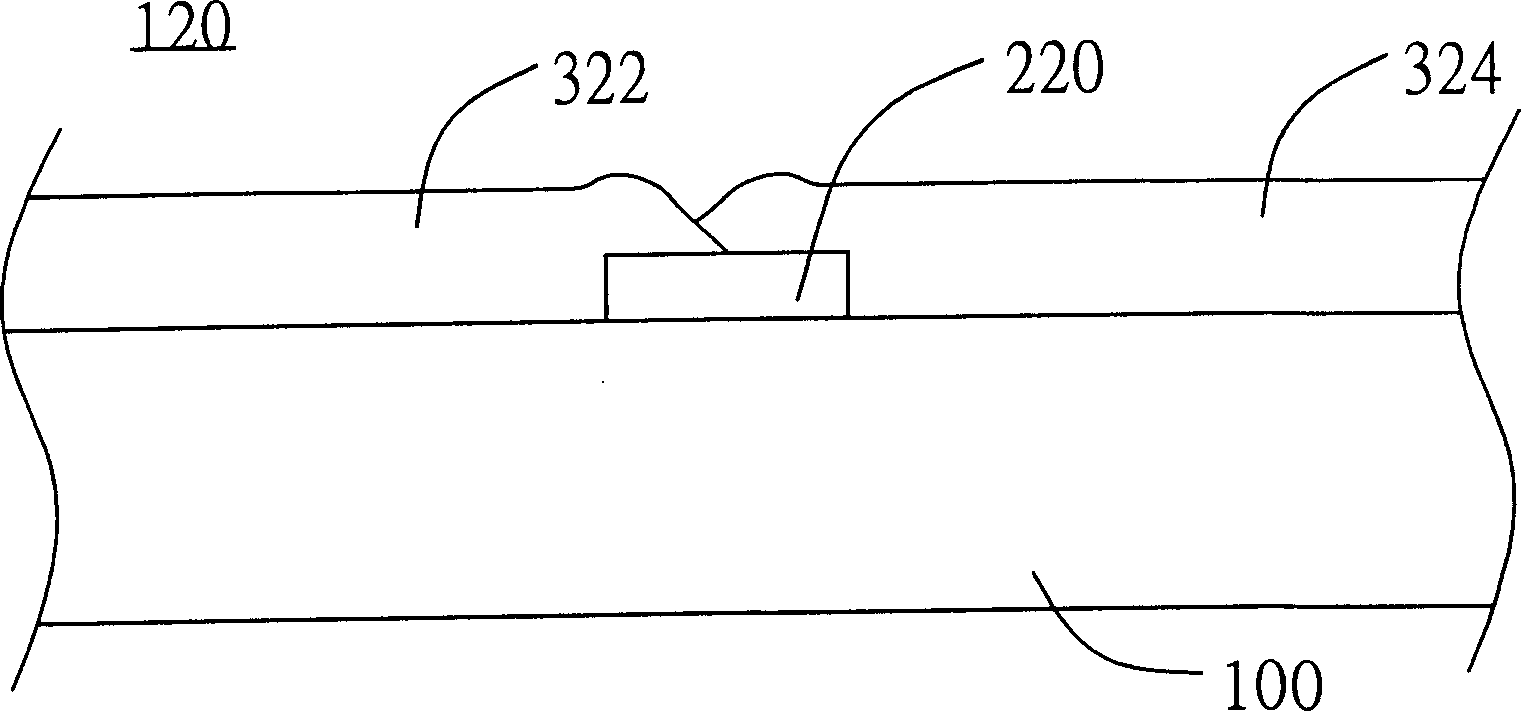

[0025] The color filter (CF) of the liquid crystal display of the present invention mainly stacks a light shielding on the black resin film of the CF frame to increase the optical density of the CF frame and form a frame with at least two resin layer films.

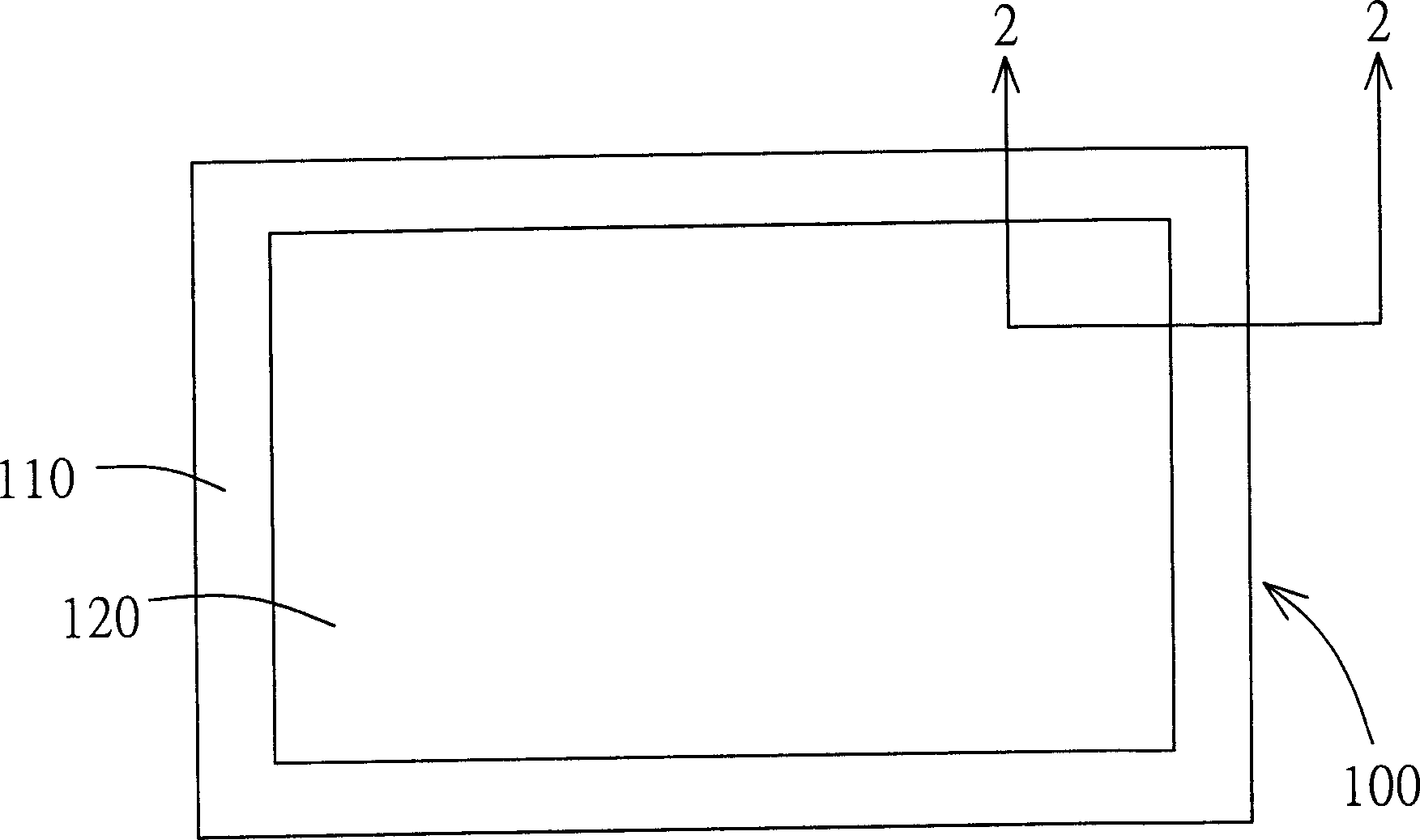

[0026] Please refer to figure 1 , Shows a schematic diagram of a color filter substrate. The substrate 100 of the color filter includes a border region 110 and an array region 120. The border area 110 surrounds the display area 120.

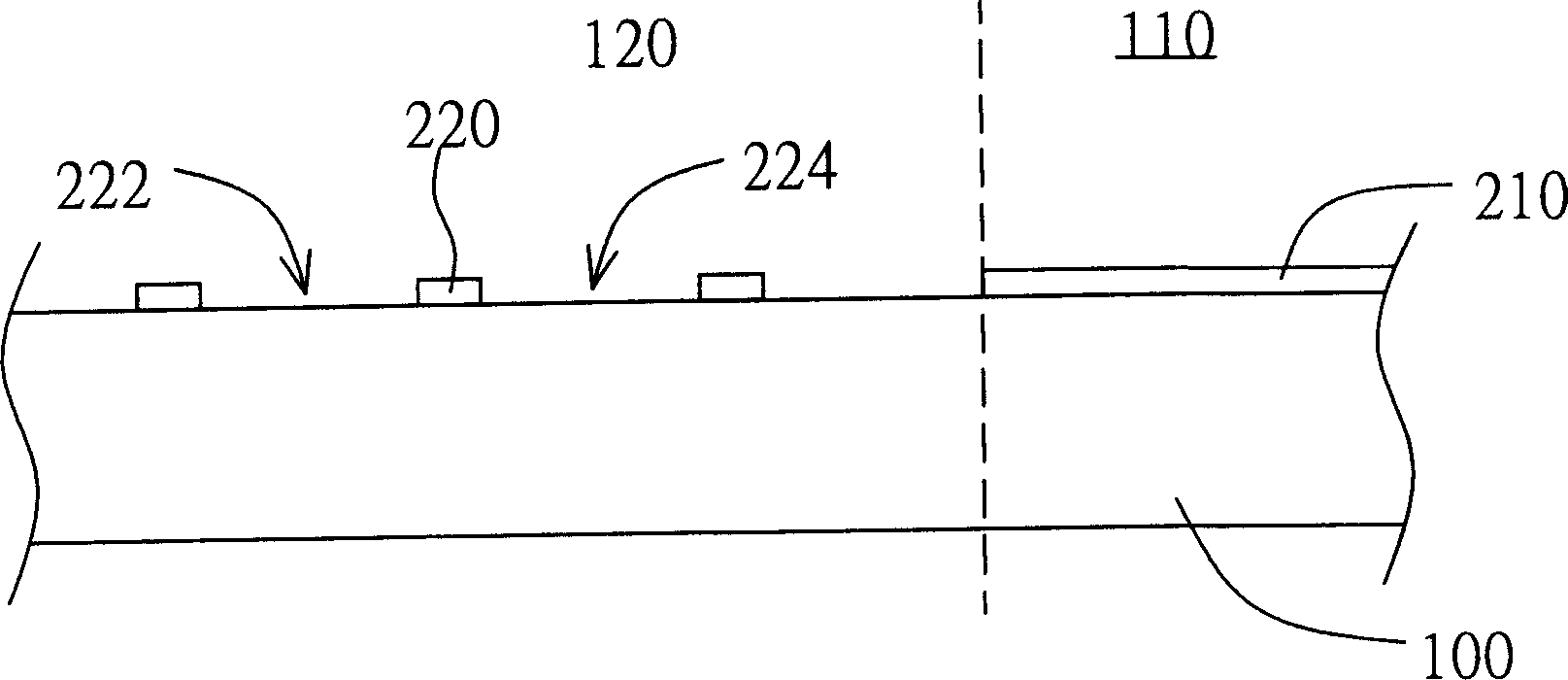

[0027] When manufacturing color filters, the black matrix process is first carried out, and then the process of RGB color photoresist is carried out. Please refer to figure 2 , Shown along figure 1 An enlarged view of the section line 2-2. The black matrix process is to form a black matrix (Black Matrix; BM) on the substrate 100 of the color filter. Such as figure 2 As shown, the first black resin film 210 is disposed in the frame area 110, and the second black resin film 220 is disposed in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com