Dynamic distributing system for standard gas

A standard gas, standard gas technology, used in gas/liquid distribution and storage, pipeline systems, mechanical equipment, etc., can solve the problems that limit the wide application of dynamic gas distribution method, complex instruments and equipment, and single use, and achieve good man-machine interface, the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

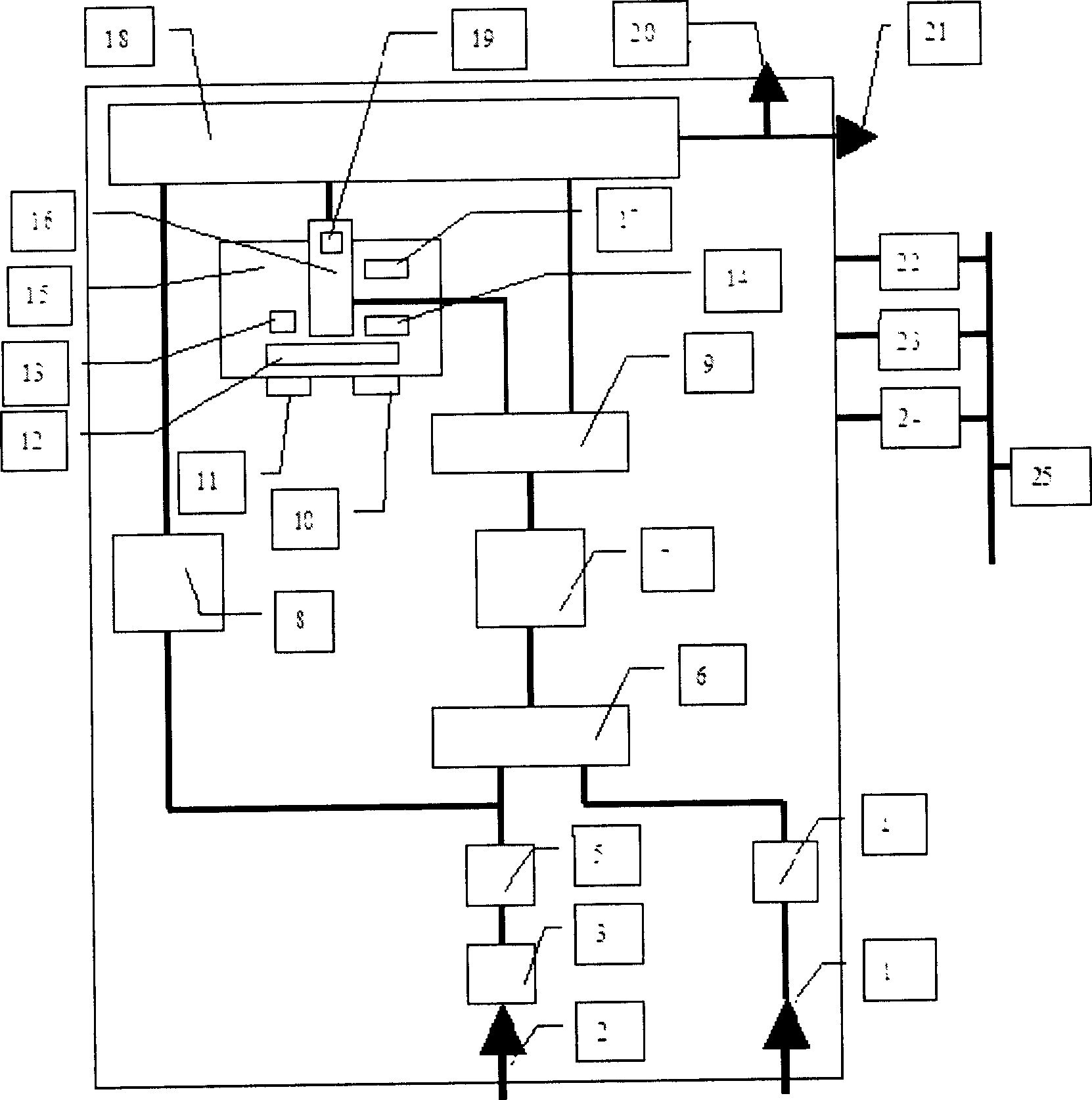

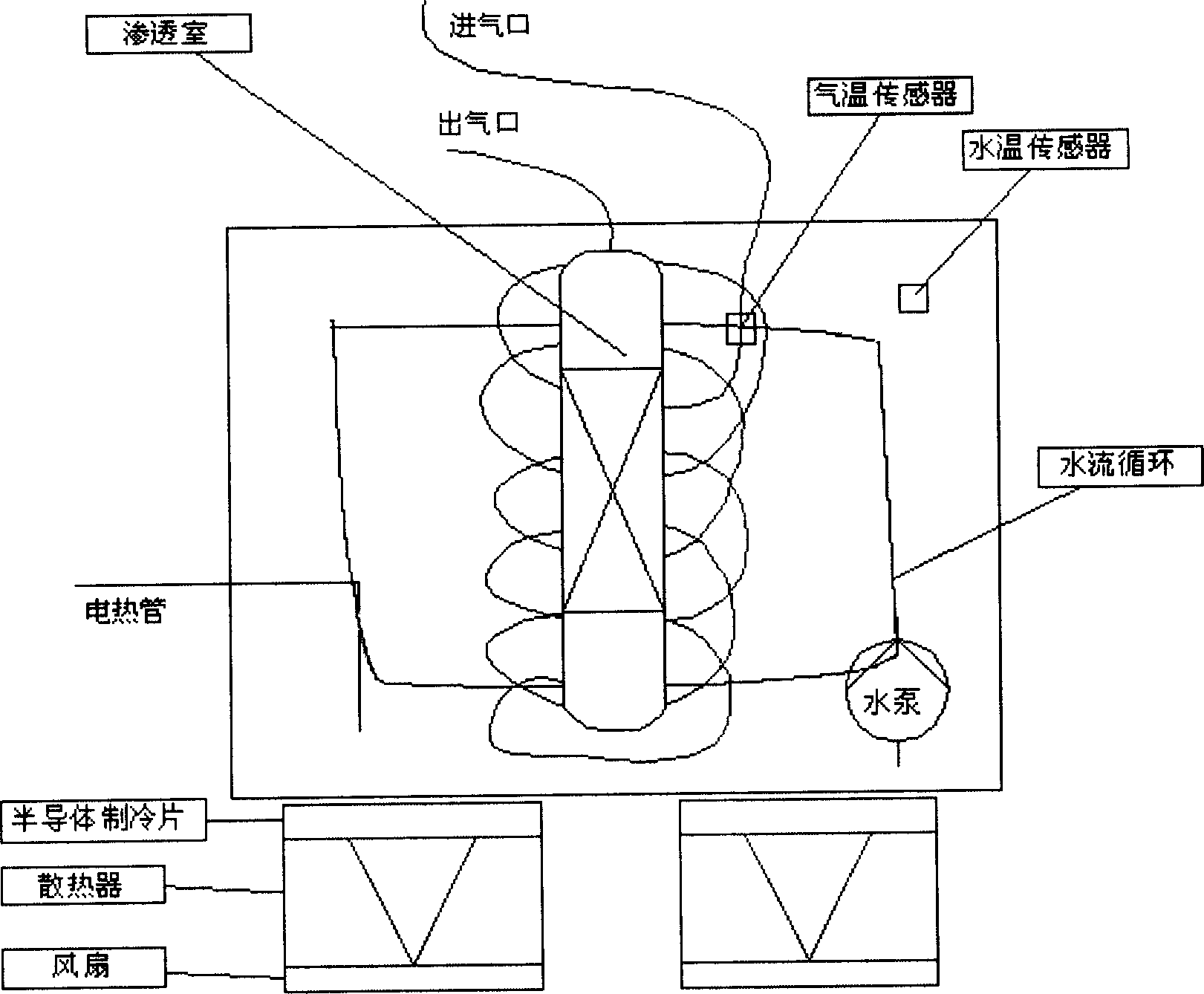

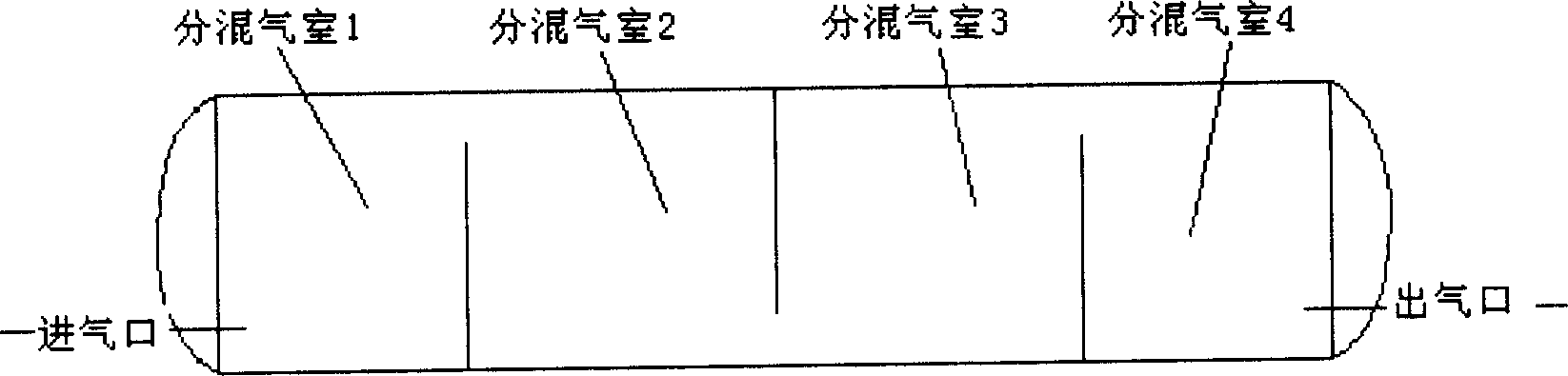

[0019] figure 1 Shown is a schematic diagram of the composition of the dynamic preparation system of a standard gas of the present invention, and the clarity of the components shown in the serial numbers in the figure is as follows:

[0020] 1. Raw material standard gas input port; 2. Raw material dilution gas input port; 3. Filter; 4. Pressure regulating valve; 5. Pressure regulating valve; 6. The first three-way reversing ball valve; 7. Mass flow device; 8 , mass flow meter; 9, the second three-way reversing ball valve; 10, cooling source; 11, cooling source; 12, heating source; 13, water temperature sensor; 14, water level sensor; 15, constant temperature water tank; 16, diffusion tube ;17. Upper water level sensor; 18. Mixed gas chamber; 19. Primary mixed gas temperature sensor; 20. Evacuation port; 21. Standard gas output port after preparation; 22. Mass flow controller; 23. PID self-tuning instrument ; 24. Mass flow controller; 25. Central computer.

[0021] Such as f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com