Method of eliminating heavy metals from garbage burning flyash

A technology for waste incineration fly ash and heavy metals, applied in the field of environmental engineering, can solve the problems of large acid consumption, inconvenient operation, difficult to put into engineering practice, etc., and achieve the effects of mild growth conditions, high efficiency and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

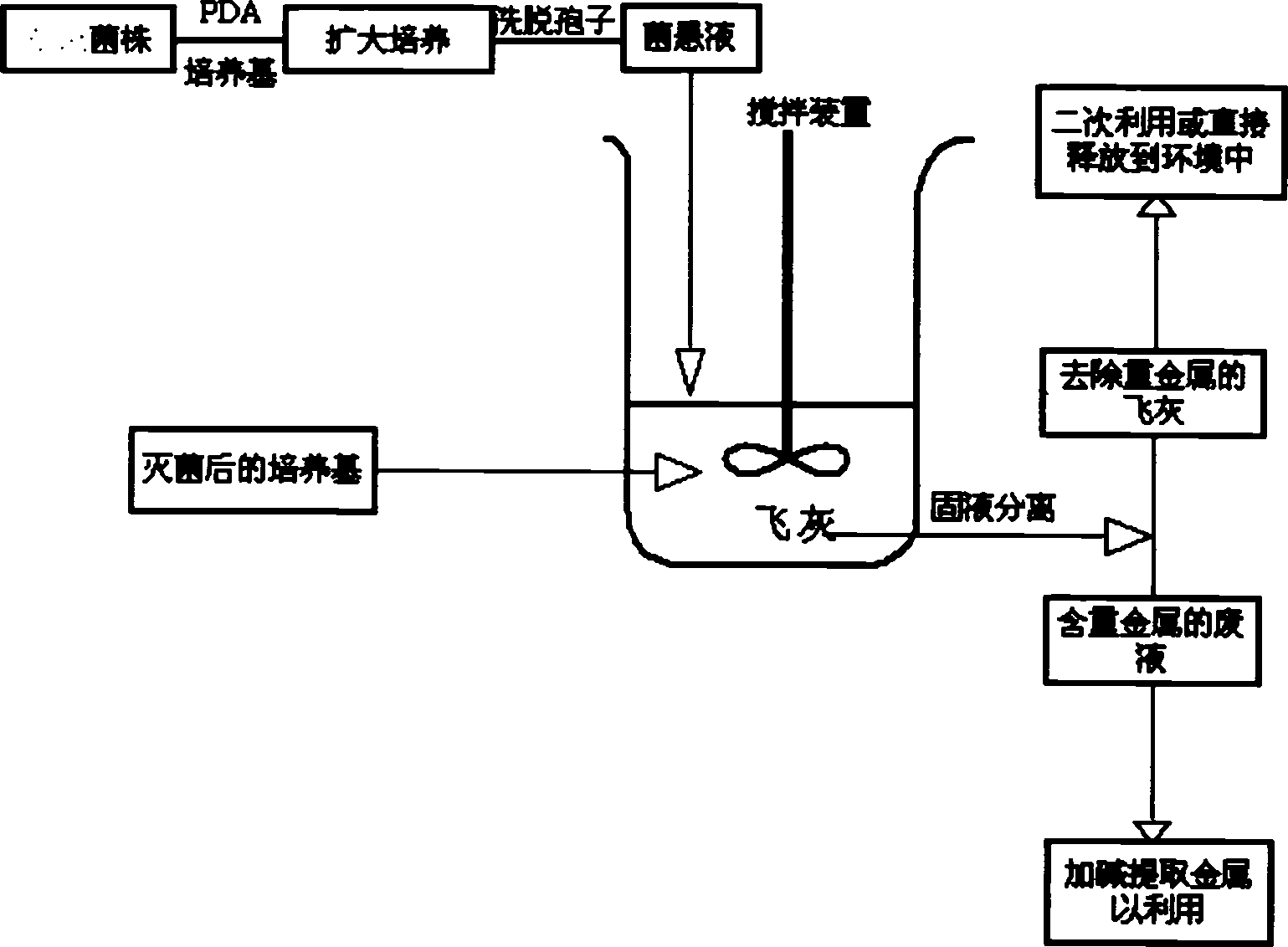

[0022] Specific implementation mode one: this implementation mode removes heavy metals in waste incineration fly ash according to the following steps:

[0023] a. Aspergillus niger is cultivated on the slope of PDA medium, cultivated at 25-35°C for 5-7 days, mature spores grow, and the surface of the colony is dark brown;

[0024] b. Elute the spores on the inclined surface with sterile deionized water, inoculate 1-10% (v / v) spore suspension into sucrose liquid medium, and then add 2-10% (w / v) garbage Incinerate the fly ash, shake and filter at a constant temperature at 25-35°C and 100-200rpm for 15-25 days;

[0025] c. Separating the fly ash after leaching into solid and liquid, the solid phase after removal of heavy metals can be used as auxiliary materials for building materials, and the liquid phase containing heavy metals is recovered by electrodeposition.

[0026] The Aspergillus niger culture medium component that this embodiment provides is:

[0027] PDA medium (pota...

specific Embodiment approach 2

[0029] Specific implementation mode two: this implementation mode is realized in this way:

[0030] 1. Fly ash sampling and metal content analysis

[0031] The fly ash is taken from a waste incineration power plant in Zhejiang Province. The raw material is municipal solid waste, and the dust removal method is a bag filter. The fly ash samples were mixed and dried at 105°C for 24 hours to constant weight, and ground to 120 mesh. Weigh 0.5000g of ash sample (dry ash) and digest it with reference to US-EPA SW-846 3050 standard acid. The metal content was determined by a full-spectrum direct-reading inductively coupled plasma optical emission spectrometer (ICP-OES). The main heavy metal contents in fly ash are shown in Table 1.

[0032] Metal

Al

Cd

Cr

Cu

Fe

mn

Pb

Zn

Metal content (mg / g)

35.67

0.06217

0.18307

0.5511

22.94

0.7362

2.15

5.252

[0033] 2. Activation and expan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com