Hand sanding tool

A grinding tool and hand-operated technology, which is applied in the field of hand-operated grinding machine tools, can solve the problems that the relative movement between the grinding disc and the grinding disc, the limitation of the tensioning effect of the grinding disc, etc. can not be ruled out, and achieve long-term carrying The effect of stroke, simple structure, and large tension effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

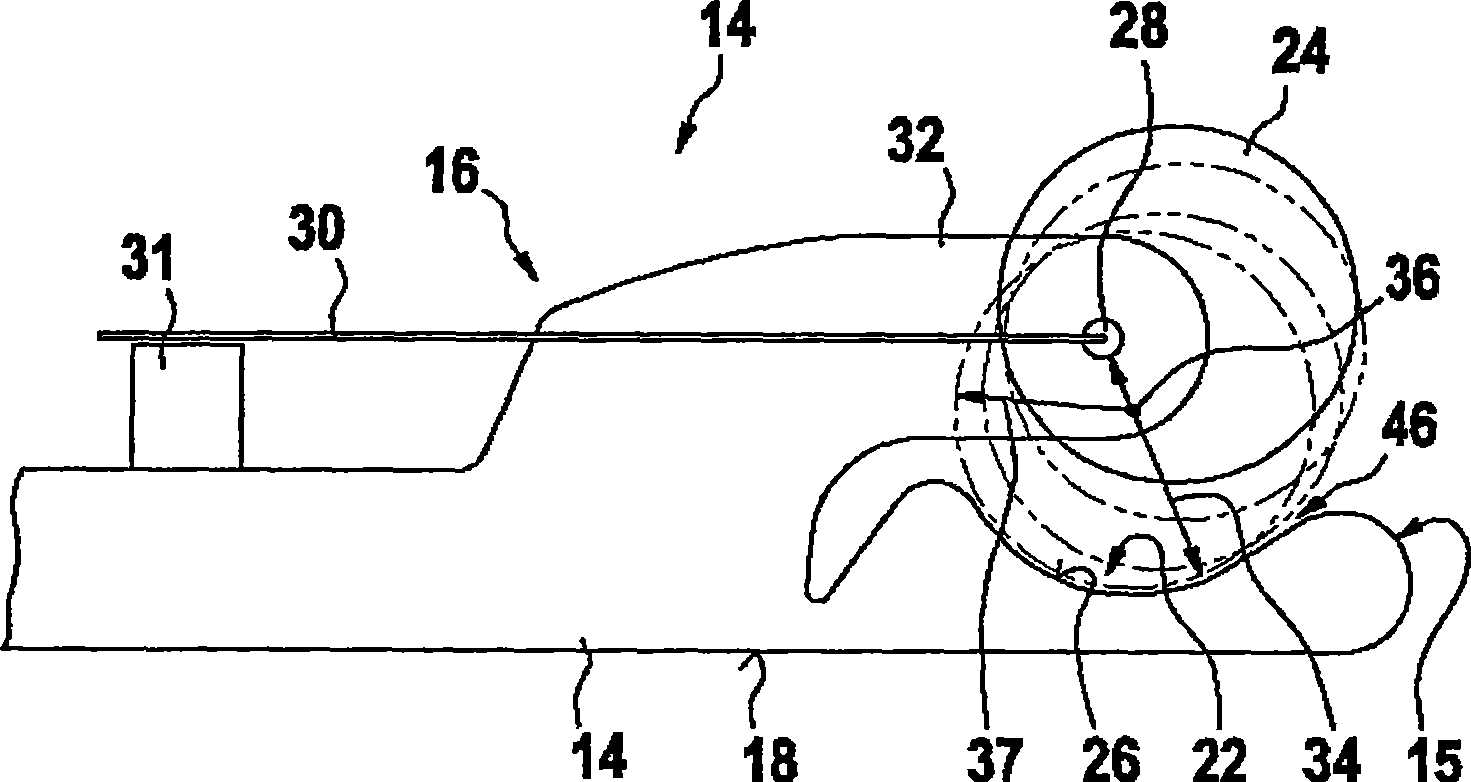

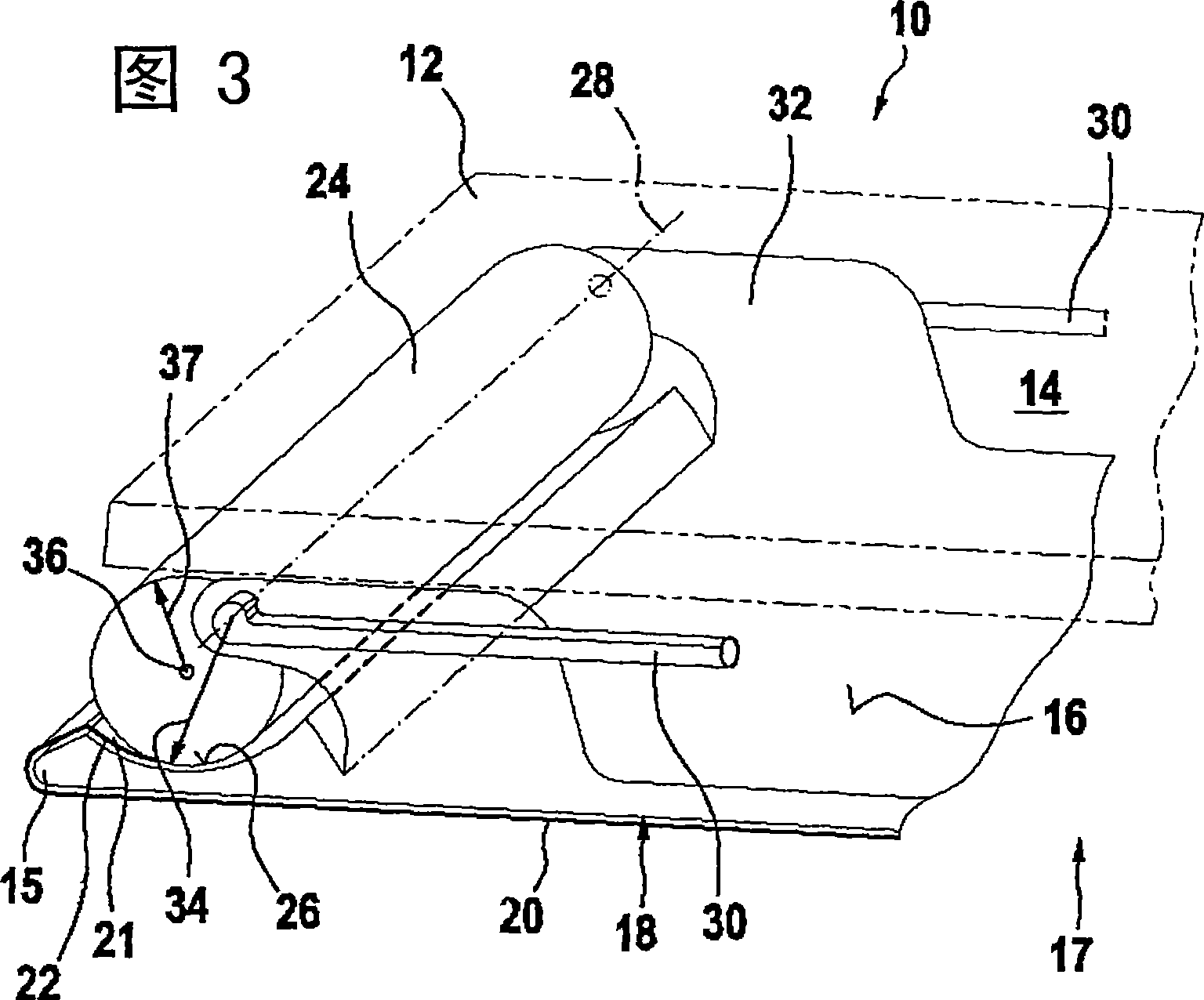

[0029] One in figure 1 The hand-operated grinding machine tool 10 shown from the front side in the middle-a hand-operated superfinishing grinder-has a housing 12 whose upper area serves as a handle 13 and its lower area carries A grinding disc 14 that can be driven vibratingly by a motor, and a grinding disc 20 can be fixed on the bottom surface 18 of the grinding disc. Here, the grinding disc 20 is wound around the front and rear edges 15 and 17 of the grinding disc 14 with its two opposite grinding disc ends 21. Here, the ends 21 of the grinding discs respectively extend into the middle of the grinding disc 14 parallel to the upper side 16 of the grinding disc. The grinding disc end 21 can be tightly clamped between a supporting surface 22 on the upper side 16 and the clamping roller 24. The clamping roller 24 can be pivoted by means of a clamping lever 30. The clamping lever 30 is bent 90° from the clamping roller 24 and extends parallel to the longitudinal extension direction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com