Motor and connector for semiconductor

A motor and permanent magnet technology, applied in the field of motors, can solve the problem of uneven distribution of reluctance, and achieve the effects of substantially uniform reluctance, increased effective magnetic flux, and increased output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 3 example 1

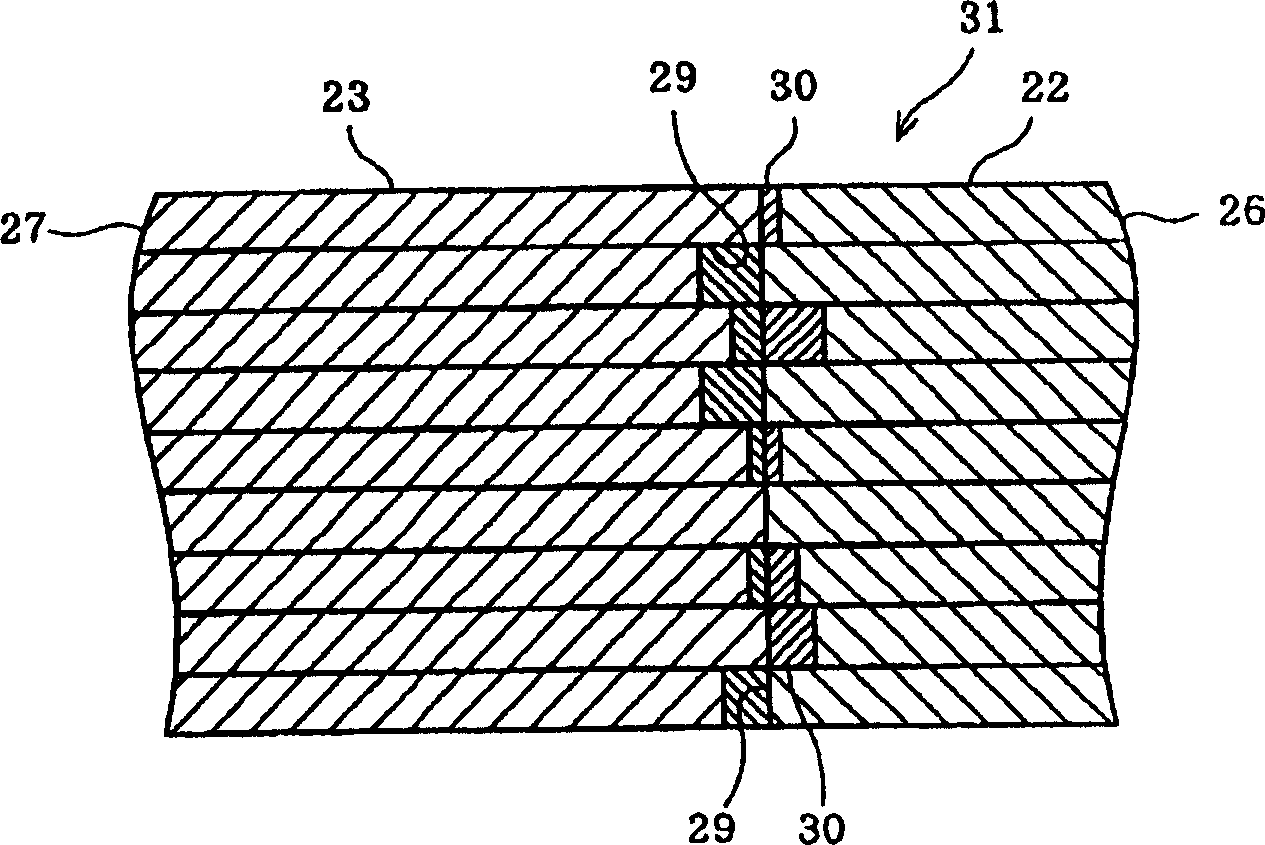

[0082] As in the third embodiment, the assembly jig 44 is also used to manufacture the stator 15 in the fifth embodiment. That is, the stator winding 25 is wound on each tooth 42, and the compound 30 is applied or sprayed on both end surfaces 43a of each split iron core 41, and then the inner peripheral end surfaces 42a of the nine teeth 42 are crimped to the mounting jig 44. on the outer peripheral surface 44a. As a result, the plurality of sawtooth-shaped fine unevenness portions 71 on both end surfaces 43 a of adjacent split cores 41 mesh with each other. In this state, split core 41 is pressurized from outer peripheral surface 43 . As a result, the plurality of saw-tooth-shaped fine unevenness portions 71 are crushed, and the joined portions of the split cores 41 are brought into close contact.

[0083] Thereby, the gap between the split iron cores 41 can be made extremely small, and the jiggle torque can be further reduced.

[0084] Figure 13 Shown is the sixth embod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com