stator and motor

A stator and stator slot technology, applied in the direction of electromechanical devices, electrical components, electric components, etc., can solve the problems of reducing motor efficiency, affecting the effective power of the motor, interference, etc., and achieve the goal of improving motor efficiency, reducing vibration and noise, and reducing magnetic flux leakage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

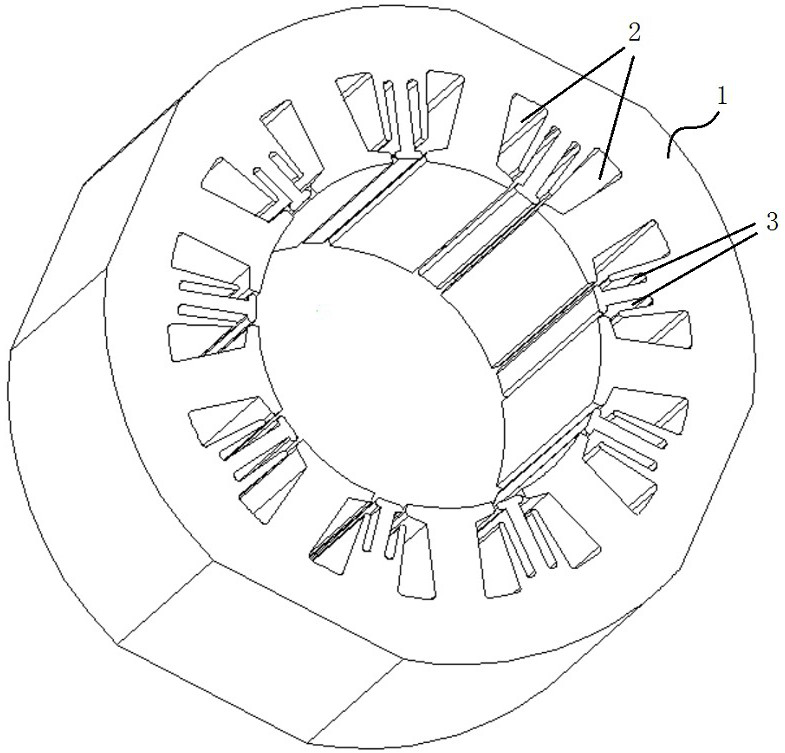

[0031] Such as Figure 1-2 As shown in , this embodiment provides a stator 1 that is provided with two magnetic isolation cavities 3 between two adjacent stator slots 2 . The magnetic isolation cavity 3 axially penetrates the two end faces of the stator 1 on the stator 1 . The magnetic isolation chamber 3 is arranged between two adjacent stator slots 2, close to the excitation winding, and two magnetic isolation chambers 3 are distributed on both sides of the magnetic pole centerline of the two adjacent stator slots 2, thereby hindering the leakage flux. produce. The magnetic isolation cavity 3 communicates with the adjacent stator slot 2 to form a through slot, which is equivalent to forming a relatively large magnetic resistance and hindering the formation of magnetic flux leakage lines.

[0032] In this embodiment, the structures of the magnetic isolation cavities 3 on the stator 1 are uniform, and the cross-section of the magnetic isolation cavity 3 is a rectangle with r...

Embodiment 2

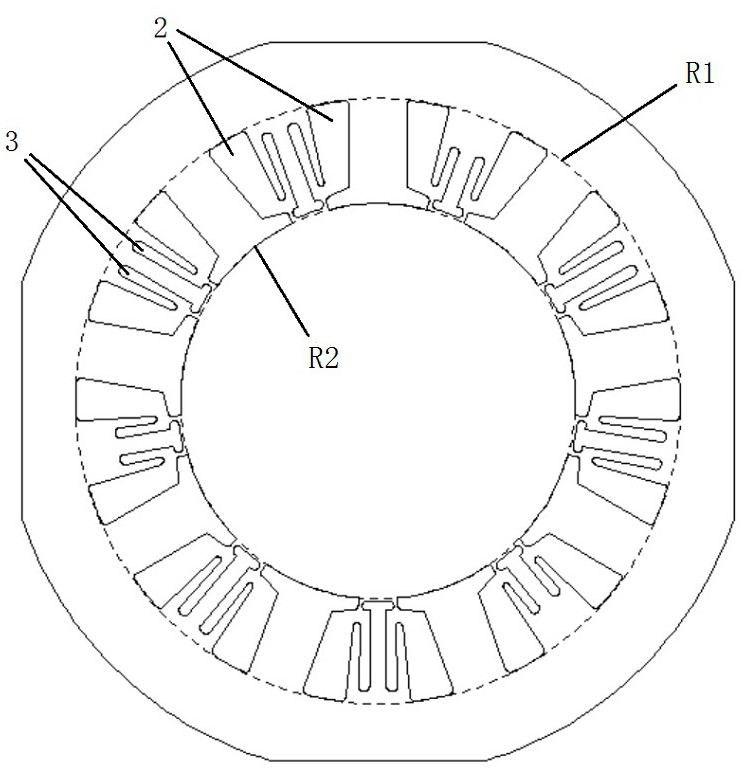

[0035] Such as image 3 As shown in , this embodiment provides a stator 1 that is provided with two magnetic isolation cavities 3 between two adjacent stator slots 2 . The magnetic isolation cavity 3 axially penetrates the two end faces of the stator 1 on the stator 1 . The magnetic isolation chamber 3 is arranged between two adjacent stator slots 2, close to the excitation winding, and two magnetic isolation chambers 3 are distributed on both sides of the magnetic pole centerline of the two adjacent stator slots 2, thereby hindering the leakage flux. produce. There is no communication between the magnetic isolation cavity 3 and the adjacent stator slot 2, so as to prevent the excessive motor reluctance torque from causing high requirements on the mechanical strength of the motor.

[0036] In this embodiment, the structures of the magnetic isolation cavities 3 on the stator 1 are uniform, and the cross section of the magnetic isolation cavity 3 is rectangular.

Embodiment 3

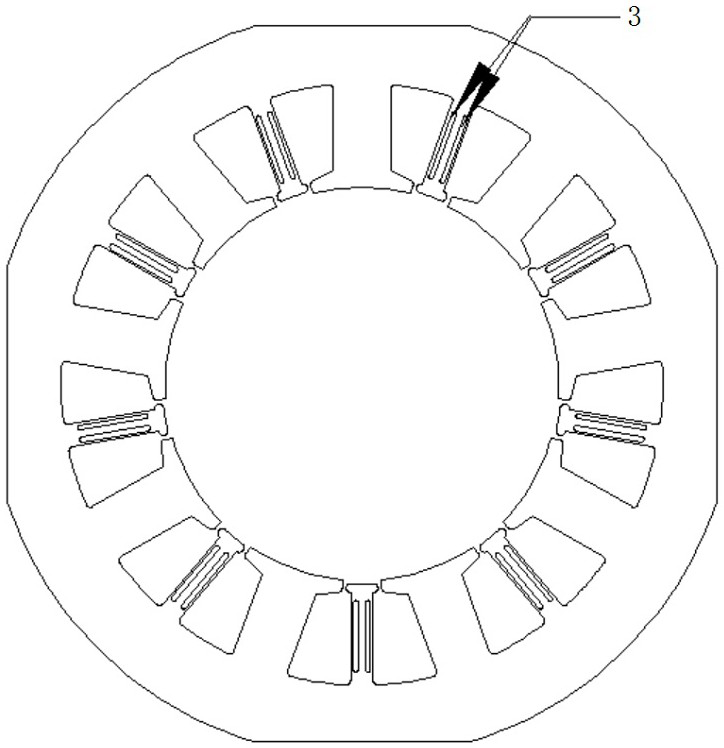

[0038] Such as Figure 4 As shown in , this embodiment provides a stator 1 that is provided with two magnetic isolation cavities 3 between two adjacent stator slots 2 . The magnetic isolation cavity 3 axially penetrates the two end faces of the stator 1 on the stator 1 . Two magnetic isolation cavities 3 are arranged between two adjacent stator slots 2, close to the field winding. The cross sections of the two magnetic isolation cavities 3 are oval, but the widths of the two magnetic isolation cavities 3 are different. The two magnetic isolation cavities 3 are arranged along the pole centerlines of the two adjacent stator slots 2, so as to prevent the generation of magnetic leakage flux. The two magnetic isolation cavities 3 are not connected to the stator slot 2, so as to prevent the excessive motor reluctance torque from causing higher mechanical strength requirements of the motor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com