Built-in permanent magnet synchronous motor and rotor magnetic bridge thereof

A permanent magnet synchronous motor, built-in technology, applied in the direction of magnetic circuit rotating parts, magnetic circuit shape/style/structure, etc., can solve the problem of low output characteristics of the motor, reduce the risk of fracture, reduce the design width, The effect of reducing stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

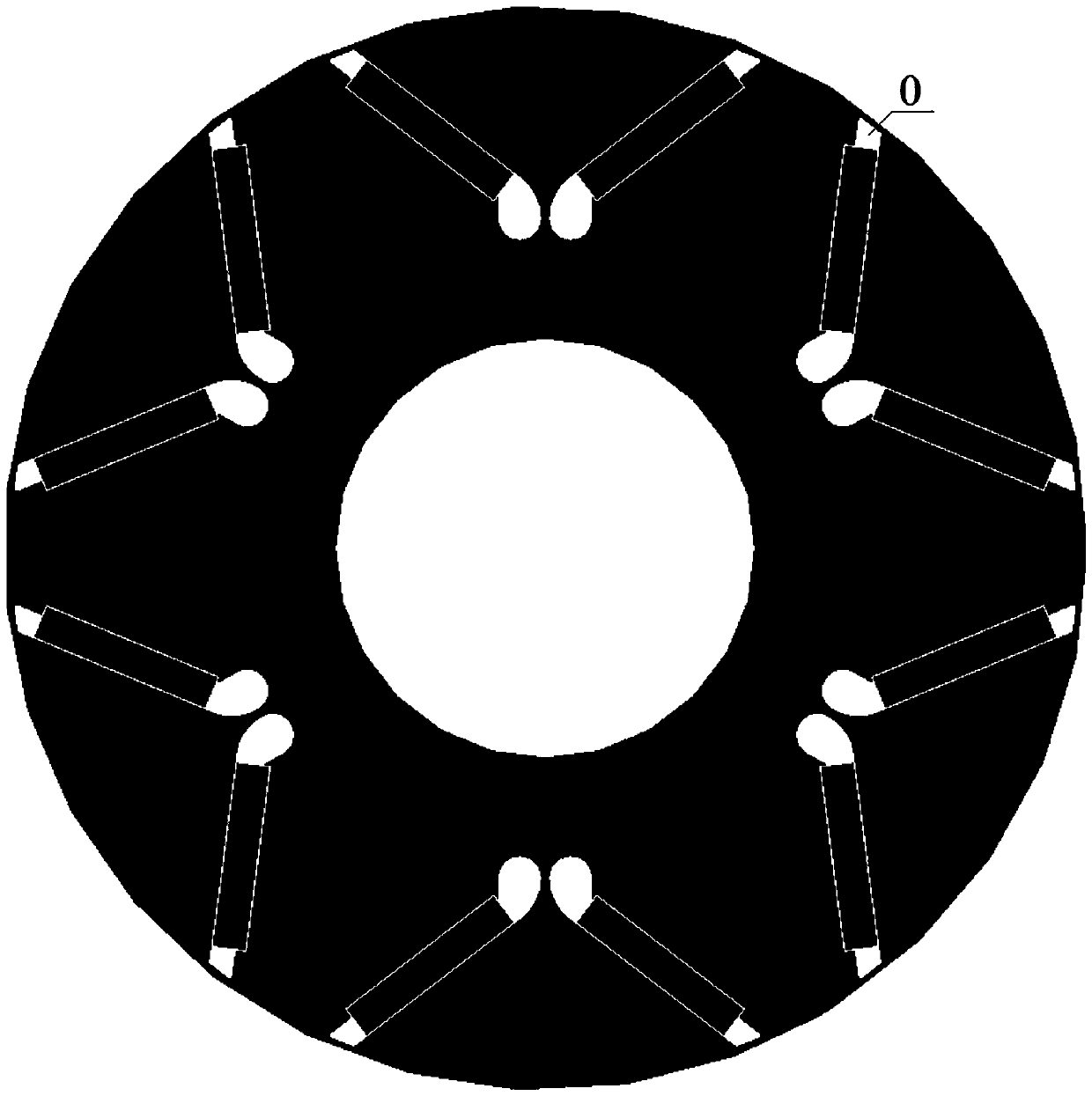

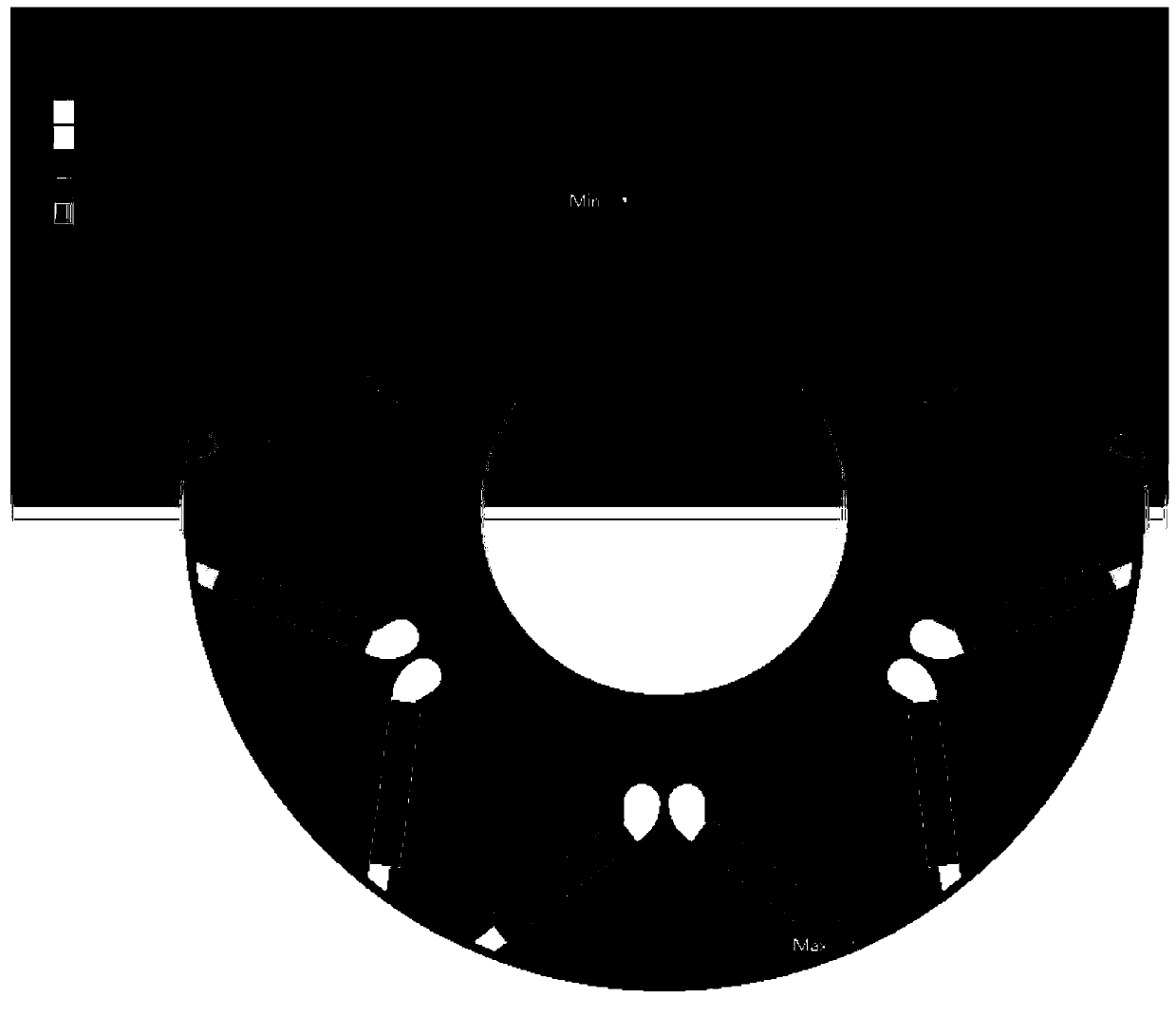

[0027] see figure 2 , the present application provides an embodiment in which the structure of the main body of the magnetic bridge is mostly the same as that of the present application, and the difference is only in the boundary 0 of the outer magnetic bridge of the magnetic bridge main body away from the air gap side, and a performance comparison study is carried out.

[0028] A built-in permanent magnet synchronous motor with a rotor outer diameter of 65 mm and a maximum speed of 20,000 rpm.

[0029] see figure 2 , image 3 with Figure 5 , in the comparative example, the width of the magnetic bridge is 1.1mm, and the shape is relatively long and narrow. When the speed is 20000rpm, the maximum value of the simulated rotor magnetic bridge stress is 1089MPa; the maximum value of the simulated motor output torque is 259Nm; the average value of the motor efficiency is 96.89%.

[0030] see figure 1 , Figure 4 with Image 6 , the magnetic bridge shape disclosed in this ...

Embodiment 2

[0036] see Figure 7 with Figure 8 , the magnetic isolation bridge solution provided in this embodiment, when the magnetic bridge width is 0.5mm, when the rotating speed is 20000rpm, the maximum value of the simulated rotor magnetic bridge stress is 1081MPa, and the maximum value of the simulated motor output torque is 265Nm; the motor efficiency is average The value is 96.85%.

[0037] The parameters of the two design schemes with different magnetic bridge widths are compared as follows:

[0038] project

comparative example

this application

Compared

in conclusion

Magnetic bridge stress (MPa)

1089

1081

0.7%

The two are basically equivalent

Motor output torque (Nm)

259

265

2.3%

This application has certain advantages

Motor efficiency (%)

96.89

96.85

-0.04%

The two are basically equivalent

[0039] Wherein, the magnetic bridge width of the comparative example is 1.1 mm, and the magnetic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com