Corn ear picking roller pair, corn harvester header and corn harvester

A corn harvester and ear picking roller technology, which is applied in the direction of headers, harvesters, agricultural machinery and implements, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

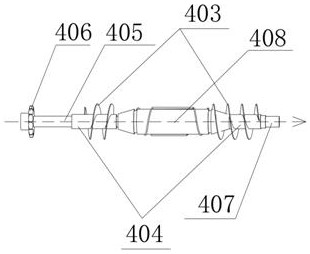

[0028] Such as Figure 2 to Figure 3 Commonly shown, a kind of fringe-picking pair of rollers is specially used in the present invention for the horizontal and horizontal arrangement of the fringe-picking rollers, including the first fringe-picking roller 401 and the second fringing-picking roller 402 with the same or different structures. The structure of roller 401 and the second fringing roller 402 is different; The blade 403 and the guide blade are used to transfer the corn stalks passing through the stalk feeding mechanism 3 to the middle position of the first ear removal roller 401 or the second ear removal roller 402 . The outside of one of the second shafts 404 is provided with a third shaft 405, and the outside of the other second shaft 404 is provided with a fourth shaft 407. The third shaft 405 and the fourth shaft 407 are rotatable through bearings respectively. is located on the header frame 1. The outer side of the third shaft body 405 is provided with a first ...

Embodiment 2

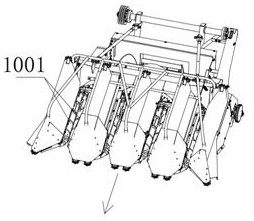

[0033] Such as Figure 4 to Figure 6Commonly shown, setting the forward direction of the header, a corn harvester header includes a header frame 1, and a straw cutting mechanism 2, a straw feeding mechanism 3, and an ear picking mechanism arranged on the header frame 1. Mechanism 4, ear transmission mechanism 5. The straw cutting mechanism 2 and the straw feeding mechanism 3 are arranged at the front end of the cutting platform frame 1, the rear of the straw feeding mechanism 3 is provided with an ear-picking mechanism 4, and the rear of the ear-picking mechanism 4 is provided with a hay cutter 6, and the hay cutter The rear end of 6 is fixed on the corn harvester body.

[0034] The stalk cutting mechanism 2 is used to cut off the corn stalks in the field. The stalk feeding mechanism 3 is used for clamping and transporting the corn stalks cut by the stalk cutting mechanism 2 to the ear picking mechanism 4 . The ear picking mechanism 4 is used to separate the corn stalks fro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com