Multi-spindle processing center with rotary table

A processing center and multi-spindle technology, which is applied in metal processing, metal processing equipment, metal processing machinery parts, etc., can solve the problems of unfavorable space rational use, excessive occupied area, and large lateral width of multi-spindle processing centers, so as to improve the site Utilization rate, the effect of reducing the width of the overall design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

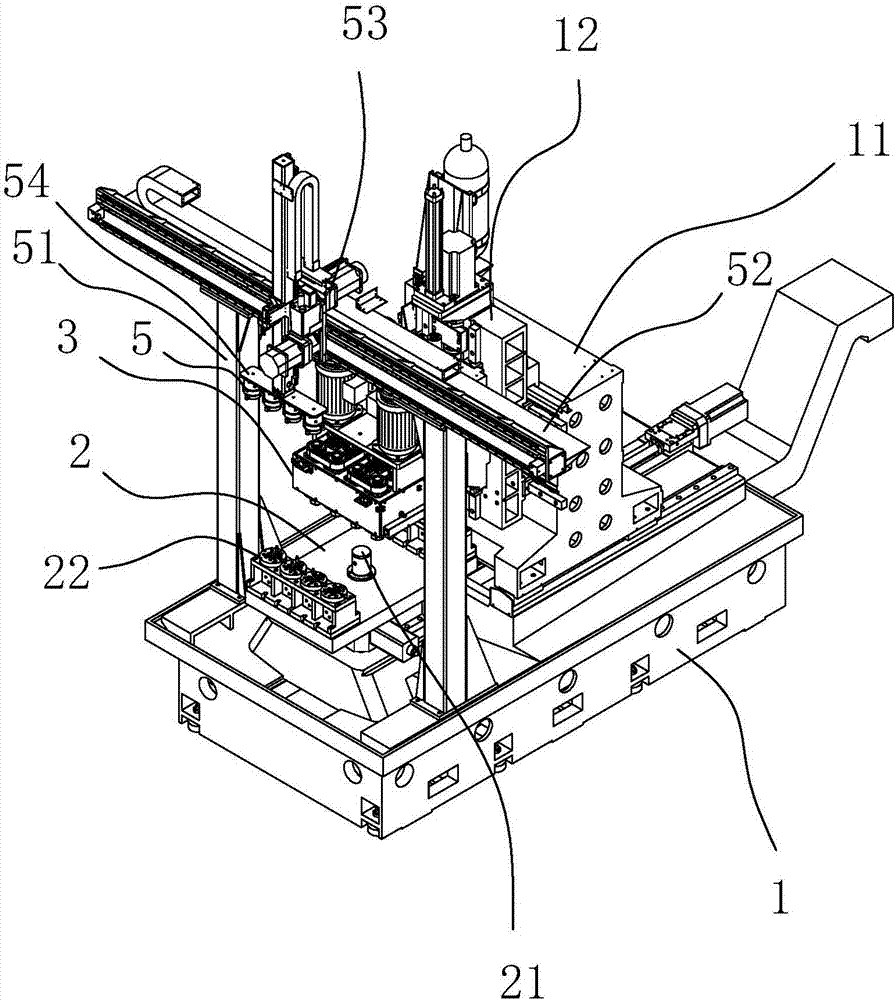

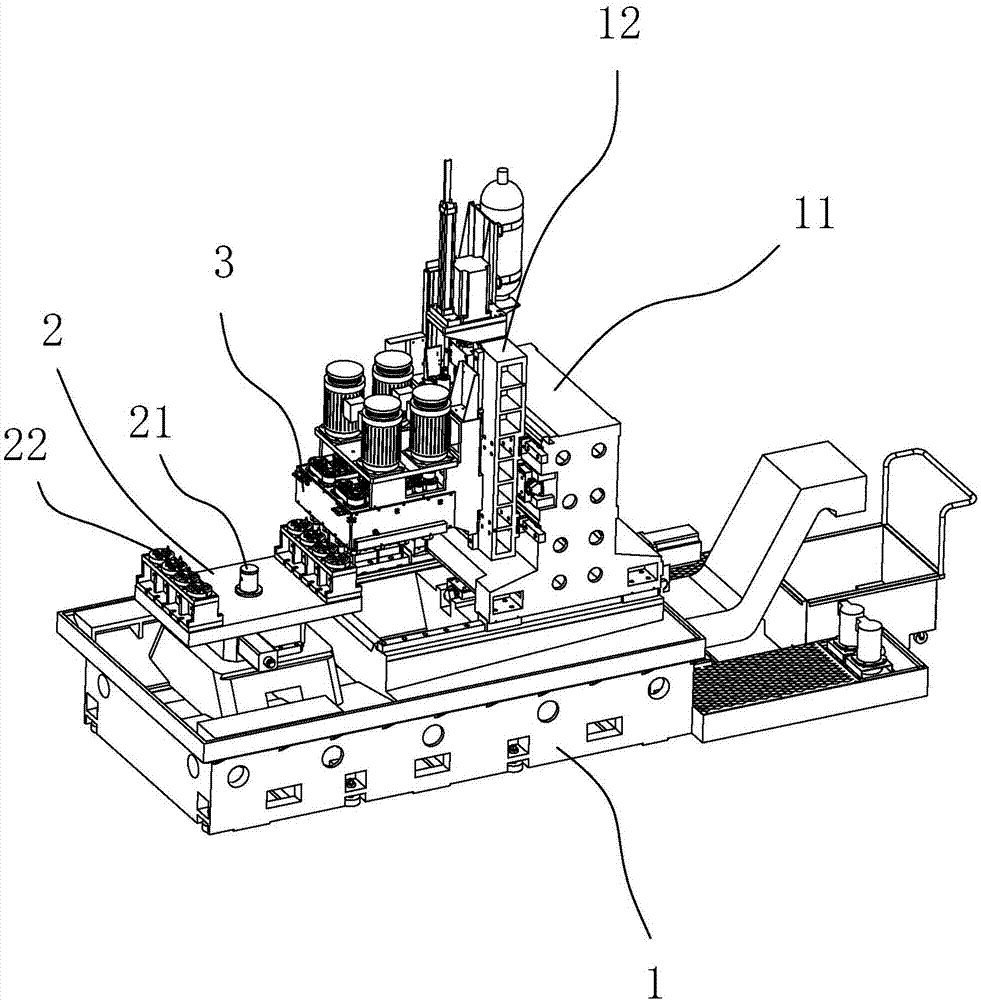

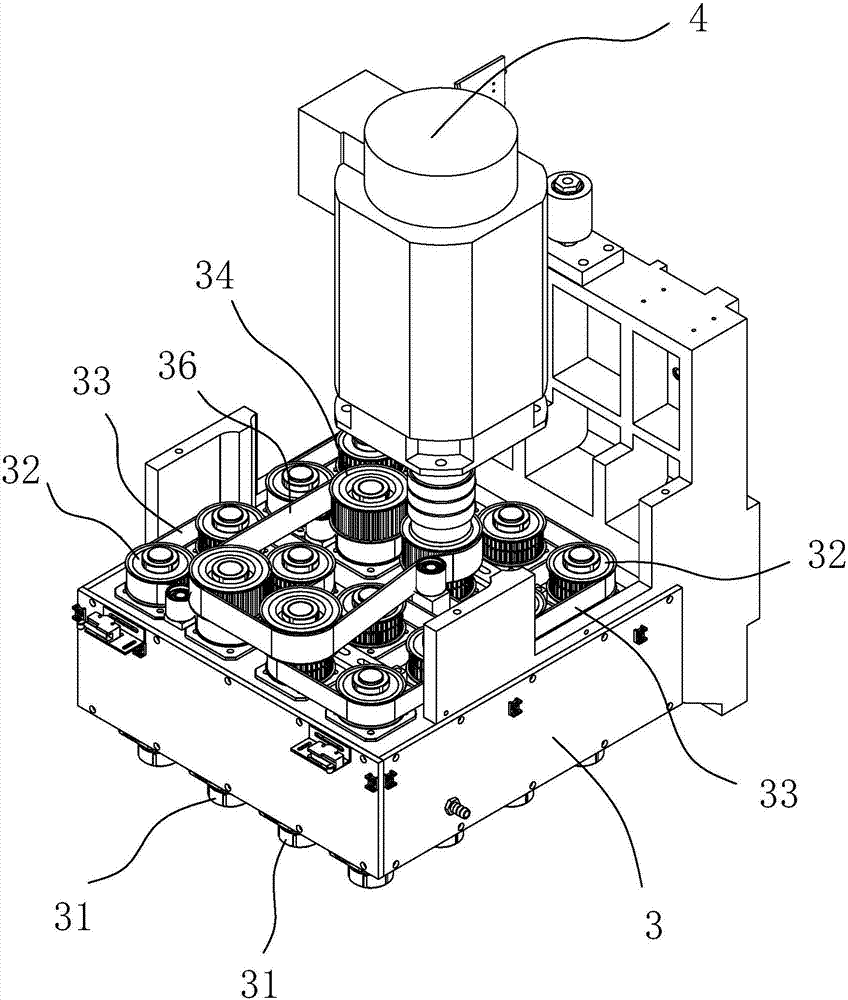

[0021] refer to Figure 1 to Figure 5 , the present invention is a multi-spindle machining center with a turntable, comprising a machine base 1, a machine frame 11 moving along the Y direction on the machine base 1, a headstock seat 12 installed on the top of the machine frame 11, and a headstock seat that can be mounted on the machine tool base 1. 12, the multi-spindle box 3 moving along the Z direction, the machine tool base 1 is located on the side where the multi-spindle box 3 is located is also provided with a turntable 2 that can rotate around the Z axis, and the inner and outer sides of the turntable 2 along the Y direction are respectively provided with straight lines. Several workpiece fixtures 22 arranged at intervals, a plurality of machining spindles 31 arranged in a matrix are arranged in the multi-spindle box 3, and the number and spacing of each row of machining spindles 31 in the multi-spindle box 3 are related to the workpiece fixtures arranged in rows. 22 cor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com