Inductor and base therefor

A technology of inductors and fitting parts, applied in the directions of inductors, fixed inductors, fixed signal inductors, etc., can solve the problems of increasing the defective rate of inductors, time-consuming and cost-consuming, magnetic leakage, etc., and improve the comprehensive manufacturing process. Ability index, improve electromagnetic shielding, reduce electromagnetic interference effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

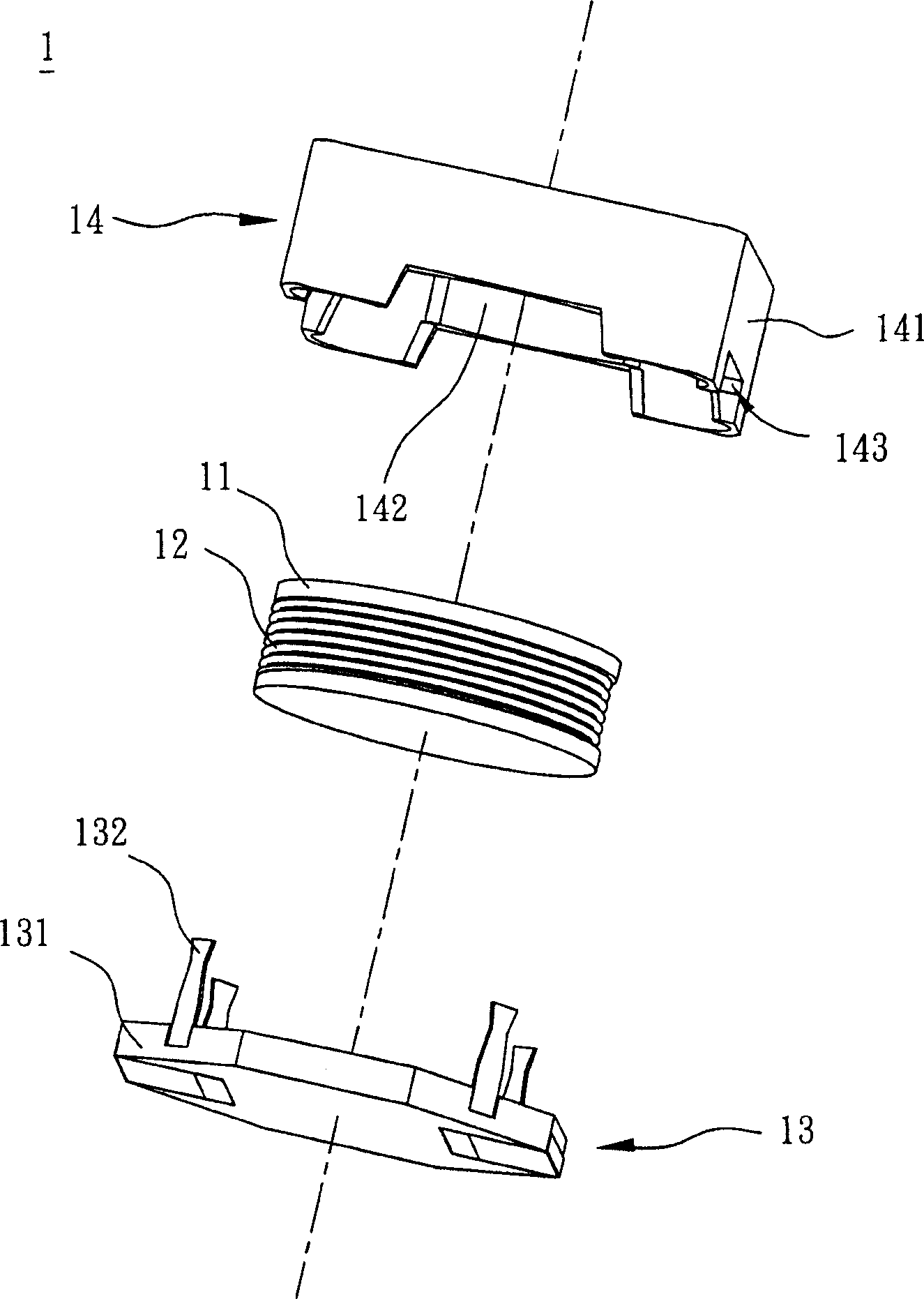

[0020] The inductor and its base according to a preferred embodiment of the present invention will be described below with reference to related drawings.

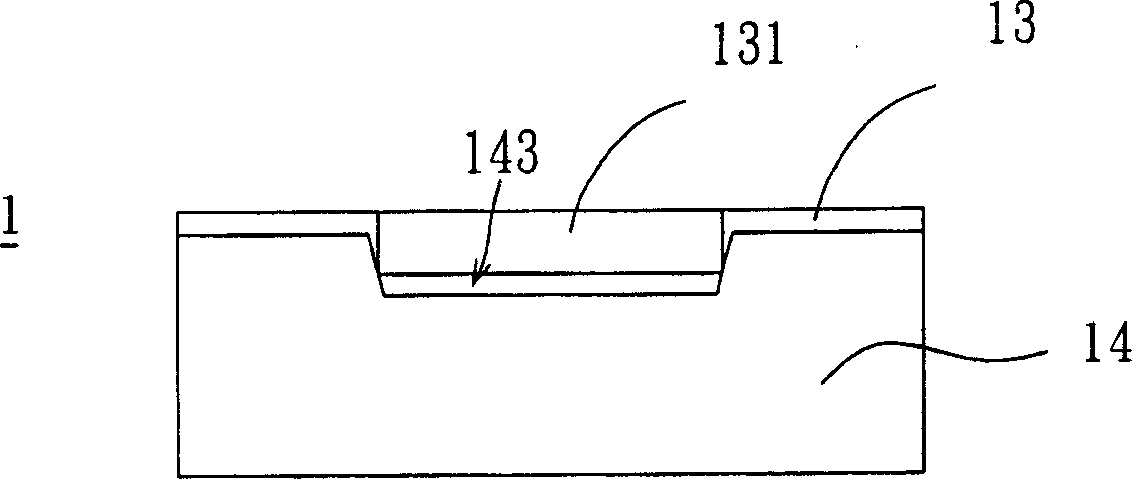

[0021] Please also see Figure 4 and Figure 5A , Figure 4 is a three-dimensional exploded view of the inductor of the present invention, and Figure 5A It is a schematic diagram of the base of the inductor of the present invention. The inductor 5 of the preferred embodiment of the present invention includes an iron core 51 , a coil 52 , a hat-shaped iron core 53 and a base 4 . The iron core 51 is made of a drum-shaped magnetic material, and the coil 52 is wound on the iron core 51 . The base 4 is connected to one end of the iron core 51 , and the connecting pins 46 of the base 4 are bent toward the iron core 51 , and the wire ends of the coil 52 can be wound on each connecting pin 46 .

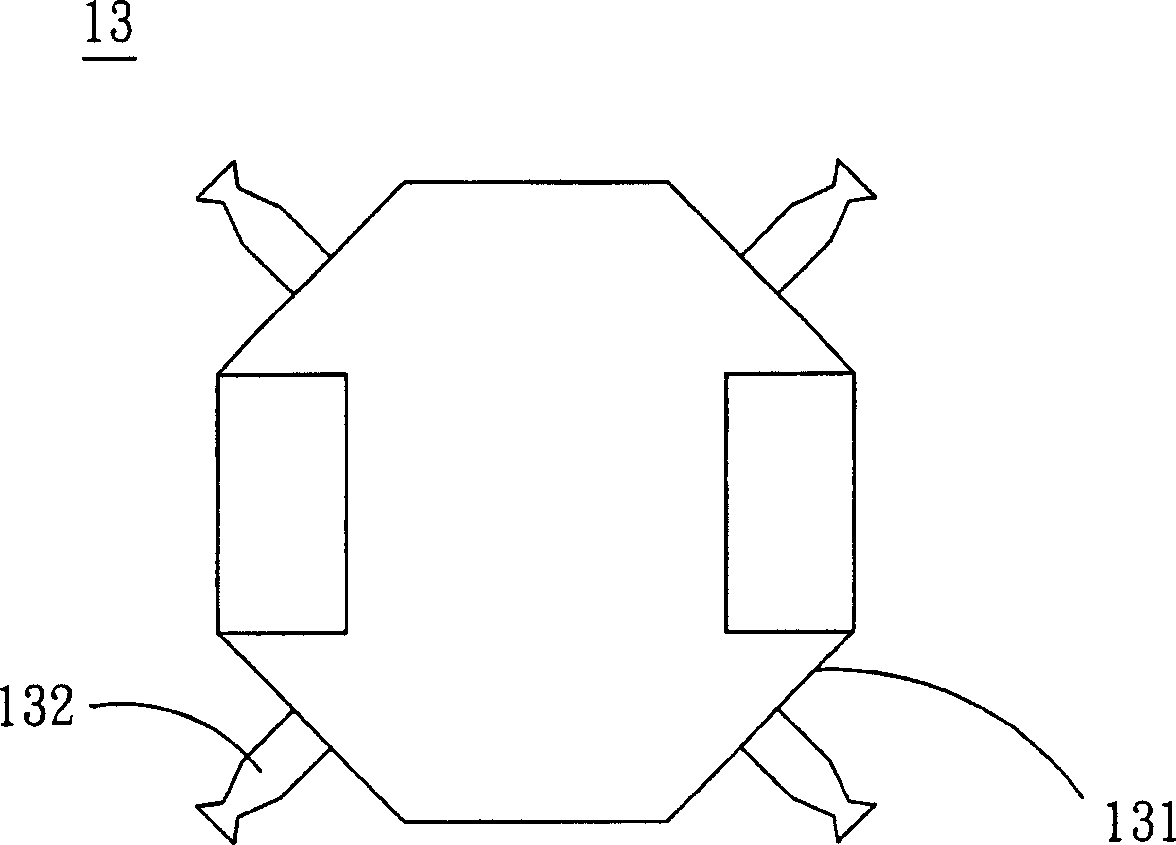

[0022] like Figure 5A As shown, the base 4 is approximately octagonal, has two opposite horizontal sides 41, two opposite vertica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com