Lubricating oil viscosity index improver

A technology for improving viscosity index and lubricating oil, which is applied in lubricating compositions, additives, petroleum industry, etc. It can solve the problems of thickening ability, shear stability, oil cleanliness, and high price of viscosity index improvers. Achieve the effect of improving shear stability and inhibiting thermal oxidation reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

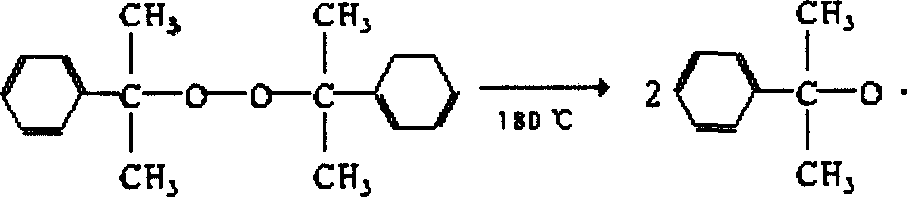

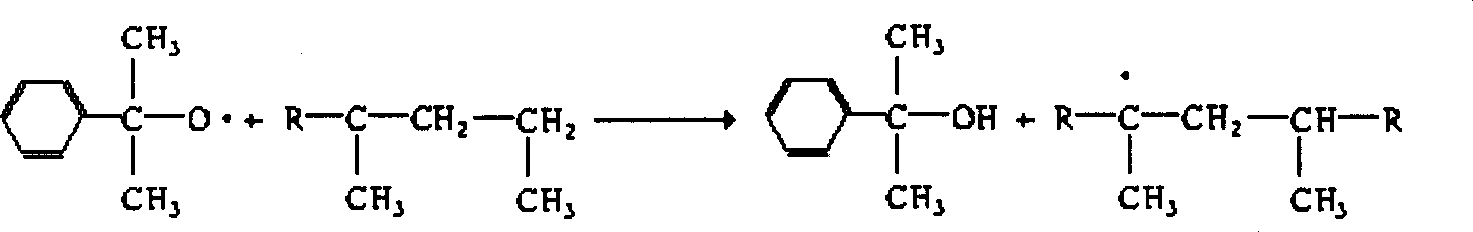

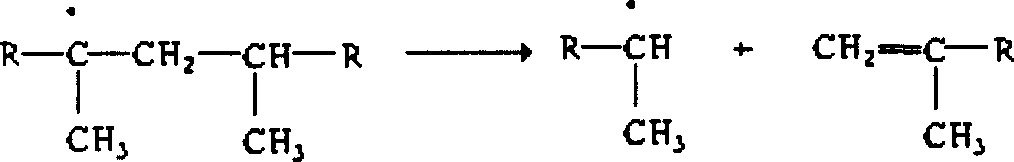

Method used

Image

Examples

Embodiment 1

[0037] Reaction equipment:

[0038] An intermittent stirring tank with an effective volume of 25 liters, the inner diameter of the tank is φ0.25 meters, the height is 0.6 meters, and there are 4 vertical baffles. The stirring shaft in the center of the tank is equipped with 4 pieces of oblique agitator with a diameter of φ0.1 meters. 120 rpm. The tank has a built-in heating coil, which is heated by a circulating heat carrier, and a cooling jacket is installed outside the tank, which can quickly cool down with cooling water at the end of the reaction. A gas distribution coil is installed at the bottom of the tank for air and nitrogen, and there is a quick-open glue filling port on the top of the tank. There is a safety valve on the top of the mixing tank and a pressure regulator on the exhaust pipe.

[0039] Production of Lubricating Oil Viscosity Index Improvers:

[0040] (1) Pour the base oil into the mixing tank, and heat up while stirring. When the temperature reaches 15...

Embodiment 2

[0045] Production of Lubricating Oil Viscosity Index Improvers:

[0046] (1) Pour the base oil into the mixing tank in [Example 1], and heat up while stirring. When the temperature reaches 140°C, open the glue port, and add the ethylene-propylene copolymer cut into blocks into the tank, and use 100 Feed nitrogen gas into the bottom of the tank at a rate of ml / min, so that the pressure inside the kettle is 0.04MPa gauge pressure; slowly heat up at a rate of about 4°C / hour, sol, the temperature rises to 165°C, and the sol ends.

[0047] (2) Add a degradation accelerator, and change the gas into the bottom of the tank into air, the air flow rate is 300 ml / min, slowly heat up, keep the temperature rise rate at 5°C / hour, degrade for 3 hours, and the temperature reaches 180°C, Turn off the heat and change the gas flow to nitrogen.

[0048] (3) The temperature is lowered and kept at 145°C, the carbon chain enhancer is added into the tank, maintained for 5 hours, the temperature is f...

Embodiment 3

[0052] Production of Lubricating Oil Viscosity Index Improvers:

[0053] (1) Pour the base oil into the mixing tank in [Example 1], and heat up while stirring. When the temperature reaches 120°C, open the glue inlet, and add the ethylene-propylene copolymer cut into blocks into the tank, and use 100 Feed nitrogen gas into the bottom of the tank at a rate of ml / min, so that the pressure inside the kettle is 0 MPa gauge pressure; slowly heat up at a rate of about 4°C / hour, sol, the temperature rises to 165°C, and the sol ends.

[0054] (2) Add antioxidants.

[0055] (3) Add the carbon chain enhancer into the tank, maintain 165°C for 4 hours, cool down to 110°C, discharge and pack into barrels.

[0056] (4) Sampling, analysis and inspection. Take samples at the filling port, measure the diesel nozzle shear stability index and thickening capacity according to the Q / SY RH3001-2002 standard, and measure the chromaticity according to GB / T6540.

[0057] The components and their wei...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear stability index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com