Novel process for preparing acetamino diethyl malonate

A technology of diethyl acetamidomalonate and diethyl nitrosomalonate, which is applied in the field of preparing diethyl acetamidomalonate, which can solve the problems of difficult handling, high production cost, and low yield of products, etc. problem, to achieve the effect of increasing product yield, reducing production cost and simplifying process steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

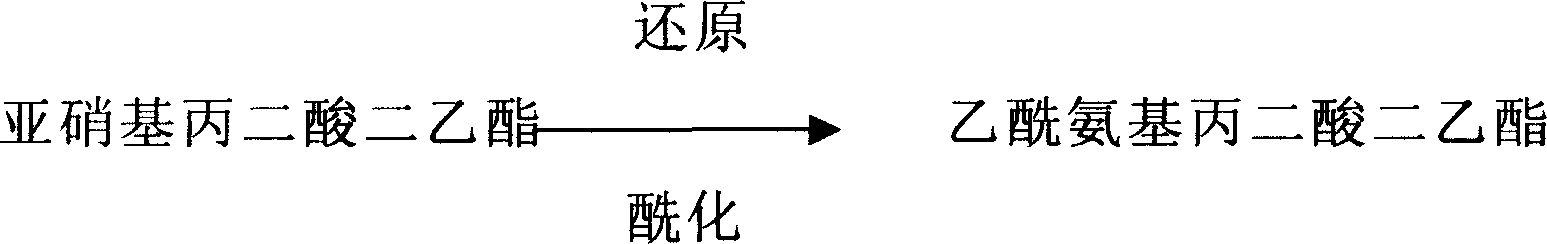

Image

Examples

Embodiment 1

[0018] Preparation of step 1 diethyl nitrosomalonate

[0019] Add 130ml of diethyl malonate (0.8mol), 35g (0.8mol) of sodium nitrite, 6ml of water and 190ml of toluene into a 1000ml three-necked flask, and dropwise add 80ml of glacial acetic acid below 5°C. After the dropwise addition, slowly raise the temperature to 40-50°C, react for 6 hours, then add water to dissolve the unreacted salt, pour it into a separatory funnel, wash the organic layer with 5% NaCl aqueous solution, discard the aqueous layer, evaporate The toluene solvent from the organic layer was 145.2 g of light yellow oily liquid, with a purity of 98.5% and a yield of 96.0% (calculated as diethyl malonate).

[0020] Step 2 Preparation of Diethyl Acetylaminomalonate

[0021] Take the above 76g of diethyl nitrosomalonate (0.4mol), 60g of acetic anhydride (0.6mol), and 36g of glacial acetic acid (0.6mol), mix well, slowly add 65g of zinc powder, and control the feeding temperature at 40-50°C . After the addition...

Embodiment 2

[0023] Preparation of step 1 diethyl nitrosomalonate

[0024] Same as step 1 of example 1

[0025] Step 2 Preparation of Diethyl Acetylaminomalonate

[0026] Take 76g of diethyl nitrosomalonate (0.4mol), 60g of acetic anhydride (0.6mol), 36g (0.6mol) of glacial acetic acid, mix well, add 2g of Rany Ni catalyst, replace the reaction system with nitrogen and hydrogen successively Air, flow hydrogen, stir and heat, control the temperature at 60-70°C, control the hydrogen pressure at 1.2MPa, react for 2-3 hours, stop the flow of hydrogen, filter while hot, and wash the filter cake twice with 40g hot acetic acid. The combined filtrates were distilled under reduced pressure to recover acetic acid. When crystals are precipitated, stop the distillation, add 100ml of distilled water to heat and dissolve, then cool in an ice-water bath and stir vigorously, let it stand for 2 hours to filter, wash the filter cake with cold distilled water, dry, and recover the mother liquor to obtain a...

Embodiment 3

[0028] Preparation of step 1 diethyl nitrosomalonate

[0029] Same as step 1 of example 1

[0030] Step 2 Preparation of Diethyl Acetylaminomalonate

[0031] Take the above 76g of diethyl nitrosomalonate (0.4mol), 81.6g of acetic anhydride (0.8mol), 36g of glacial acetic acid (0.6mol), mix well, slowly add 65g of zinc powder, and the temperature of the addition is controlled at 40-50 ℃. After the addition, react at 50-60°C for 1 hour, filter while hot, and wash the filter cake twice with 40 g of hot acetic acid. The combined filtrates were distilled under reduced pressure to recover acetic acid. When crystals are precipitated, stop the distillation, add 100ml of distilled water to heat and dissolve, then cool in an ice-water bath and stir vigorously, let it stand for 2 hours to filter, wash the filter cake with cold distilled water, dry, and recover the mother liquor to obtain a white powder 80.5 g of crystals, the melting point is 96.0-98.5°C, and the total yield of reduc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com