Internal circulation dynamic membrane bioreactor

A bioreactor and dynamic membrane technology, applied in the direction of sustainable biological treatment, aerobic process treatment, etc., can solve the problems of poor removal of pollutants, uneven mixing of activated sludge, and small cross-flow velocity of mixed liquid, etc., to achieve The effects of delaying membrane fouling, prolonging the backwash cycle, and increasing the cross-flow velocity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

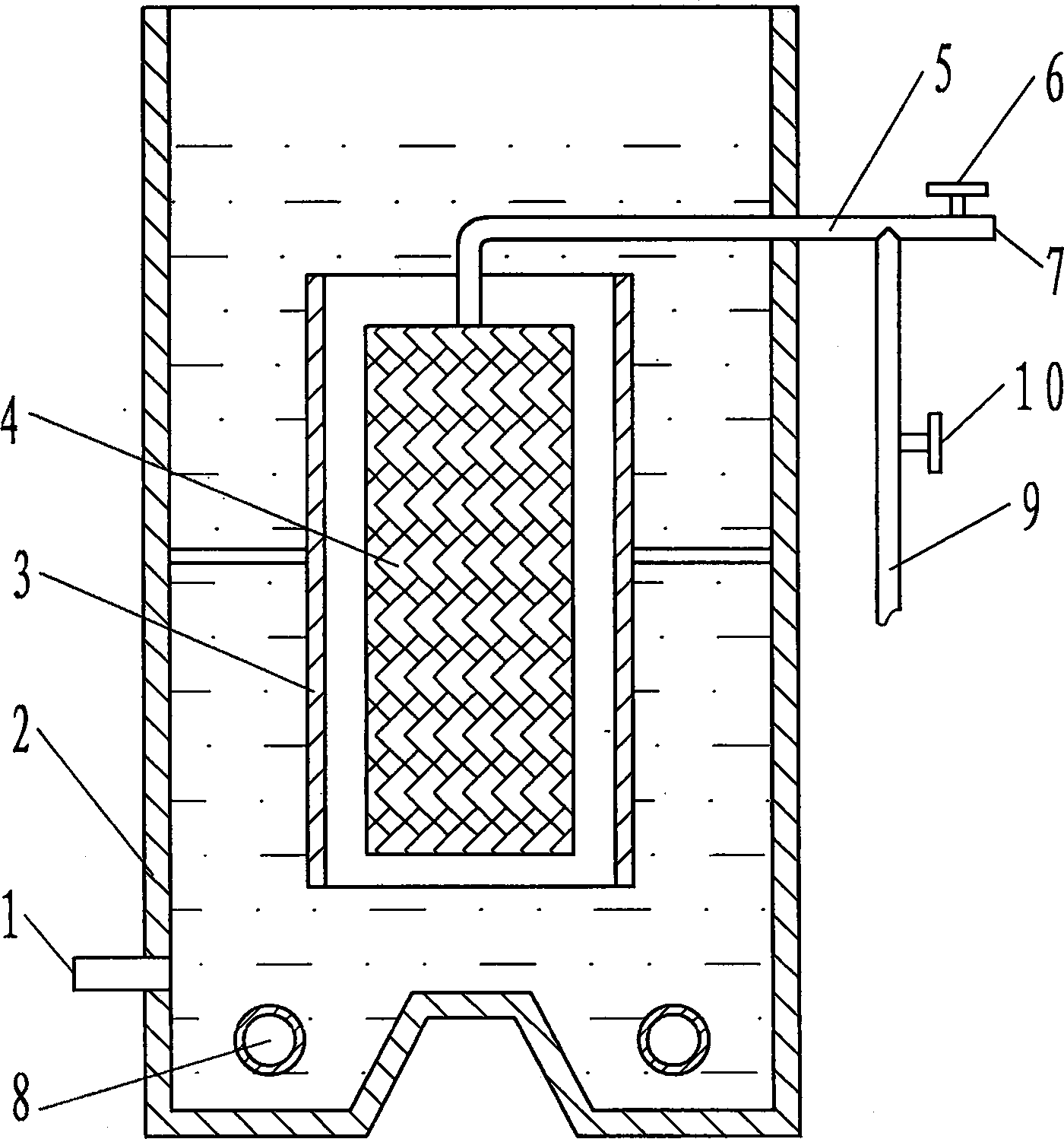

[0012] As shown in the drawings, the internal circulation dynamic membrane bioreactor of the present invention includes an outer cylinder 2 , an inner cylinder 3 , a membrane module 4 , an aeration pipe 8 and a backwash aeration pipe 9 . The lower end of the outer cylinder body 2 is sealed, the upper end is open, and the lower part is provided with a water inlet 1 . The upper and lower ends of the inner cylinder body 3 are all open, and are contained in the outer cylinder body 2, and the distance between the bottom end and the inner bottom surface of the outer cylinder body 2 is 1 / 10 of the total height of the outer cylinder body. Membrane module 4 is made of sieve silk, set in the inner cylinder 3, its upper end is provided with a water outlet pipe 5 protruding from the outer cylinder, the end of the water outlet pipe 5 is a water outlet 7, and the front of the water outlet 7 is provided with a valve 6 . A backwash aeration pipe 9 is also connected to the water outlet pipe 5...

Embodiment 2

[0016] The structure of the internal circulation dynamic membrane bioreactor is the same as in Example 1. The MLSS of the reactor is 8000mg / L, the DO is 2.0-4.0mg / L, the COD of the influent is 500mg / L, and the ammonia nitrogen in the influent is 80mg / L. During operation, when the gas-water ratio is 40:1, the effluent COD is 28mg / L, the effluent ammonia nitrogen is 1.5mg / L, and the turbidity of the effluent is 4NTU. The backwash cycle of the reactor can be stabilized at 90h.

Embodiment 3

[0018] The structure of the internal circulation dynamic membrane bioreactor is the same as in Example 1. The MLSS of the reactor is 8000mg / L, the DO is 2.0-4.0mg / L, the COD of the influent is 150mg / L, and the ammonia nitrogen in the influent is 50mg / L. During operation, when the gas-water ratio is 40:1, the effluent COD is 22mg / L, the effluent ammonia nitrogen is 1.0mg / L, and the turbidity of the effluent is 4NTU. The backwash cycle of the reactor can be stabilized at 90h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com