Composite membrane of biomimetic water catchment, preparation method and usage

A composite film and water collection technology, applied in the direction of layered products, etc., can solve the problems of not being able to meet the needs of water, low water collection efficiency, and high cost, and achieve the effects of improved efficiency, good outdoor stability, and extended service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

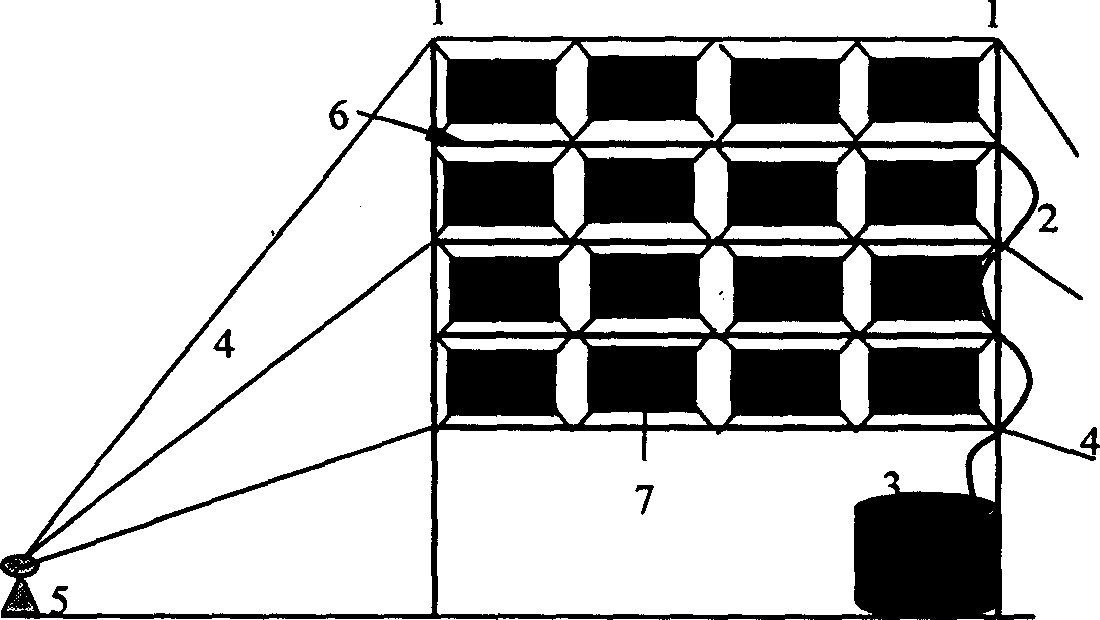

Examples

Embodiment 1

[0069] 1) Preparation of hydrophobic polymer solution:

[0070] Mix the two components of PDMS (glue solution—also called A component or A component, and solidification solution—also called B component or B component) in 10:1 parts by weight, and then add it with the glue Liquid equal weight of butyl acetate, the viscosity of the mixed system is reduced, and the hydrophobic polymer solution is prepared for subsequent use;

[0071] 2) Preparation of hydrophilic polymer solution:

[0072] Add 3g of commercially available silica hydrosol particles (average particle diameter is 5 μm) and 180g of formic acid solution (commercially available) in the reaction flask, put into the ultrasonic pool and fully ultrasonically disperse for 30 minutes, then add 30g of nylon 6 ( PA6) polymer, dissolved at 40°C for 20 minutes to obtain a hydrophilic polymer solution doped with inorganic oxide particles, set aside;

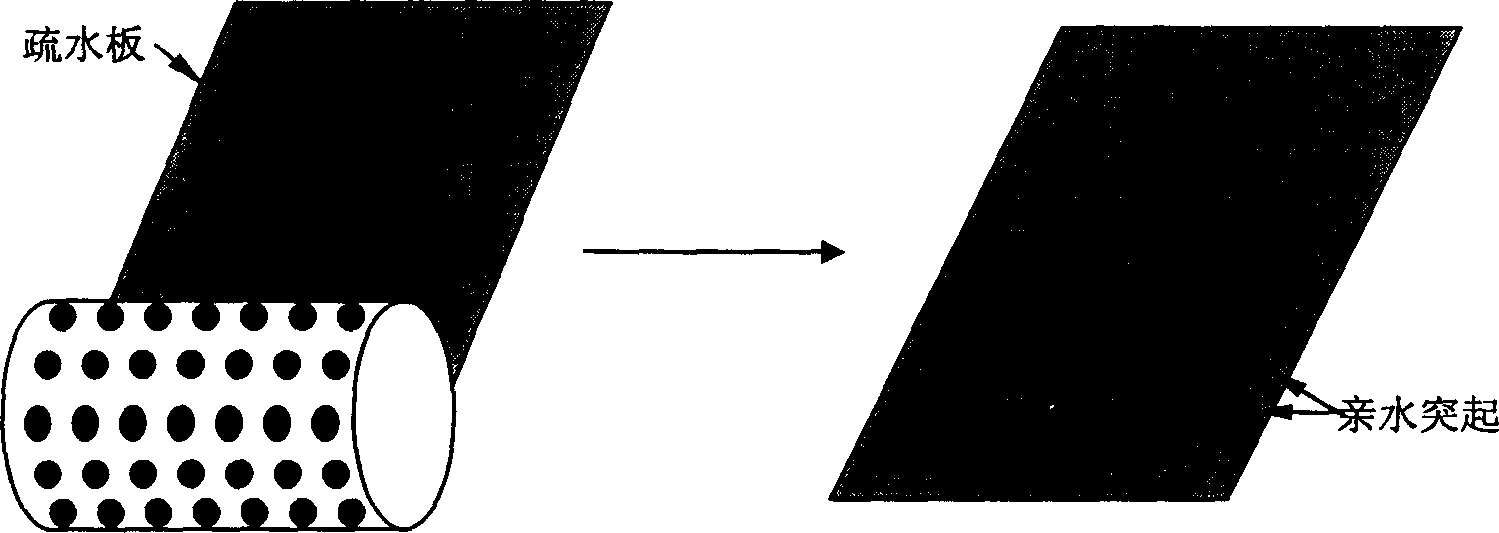

[0073] 3) Preparation of composite film:

[0074] Evenly roll-coat the PDMS ...

Embodiment 2

[0077] 1) Preparation of hydrophobic polymer solution:

[0078] With the step 1) of embodiment 1);

[0079] 2) Preparation of hydrophilic polymer solution:

[0080] Add 6g of commercially available titanium dioxide hydrosol particles (average particle diameter is 50 μm) and 180g of formic acid solution (commercially available) in the reaction flask, mechanically stir and disperse for 30 minutes, add 30g nylon 4 (PA4) polymer again, at 50 Dissolve at ℃ for 20 minutes to obtain a hydrophilic polymer solution doped with inorganic oxide particles, which is set aside;

[0081] 3) Preparation of composite film:

[0082] Evenly roll-coat the PDMS solution prepared in step 1) on 2×1m 2 on a polyethylene sheet, dried for 20 minutes to form a hydrophobic polymer film; The completely dried hydrophobic polymer coating forms protrusions with a diameter of 0.7 mm, a height of 0.4 mm, and a distance of 2 mm between the center points of the protrusions on the coating; finally, drying at 5...

Embodiment 3

[0085] 1) Preparation of hydrophobic polymer solution:

[0086] With the step 1) of embodiment 1);

[0087] 2) Handling glass beads:

[0088] Immerse glass beads with a diameter of 0.7 mm in 5 wt % hydrofluoric acid solution (commercially available), treat at room temperature for 1 hour, filter out the glass beads, wash the glass beads with clear water for 3 times, dry, and set aside;

[0089] 3) Preparation of composite film:

[0090] Evenly roll-coat the PDMS solution prepared in step 1) on 2×1m 2 On a polyethylene sheet, dry for 20 minutes to form a hydrophobic polymer film; then pour the glass beads treated in step 2) into a porous sieve bucket with a pore size of 1mm, pour the porous sieve bucket, and roll over the not completely dried Hydrophobic polymer coating, forming protrusions on the coating with a diameter of 0.5-0.8 mm, a height of 1 mm, and a distance between the center points of the protrusions of 3 mm; finally, drying at 50°C for 2 hours to obtain the biomi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com