Planetary gear

A planetary gear box, gear box technology, applied in the direction of gear transmission, gear lubrication/cooling, belt/chain/gear, etc., can solve the problems of friction corrosion, lack of lubrication of thrust bearing, unable to reach the sun gear all the way, to prevent The effect of frictional corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

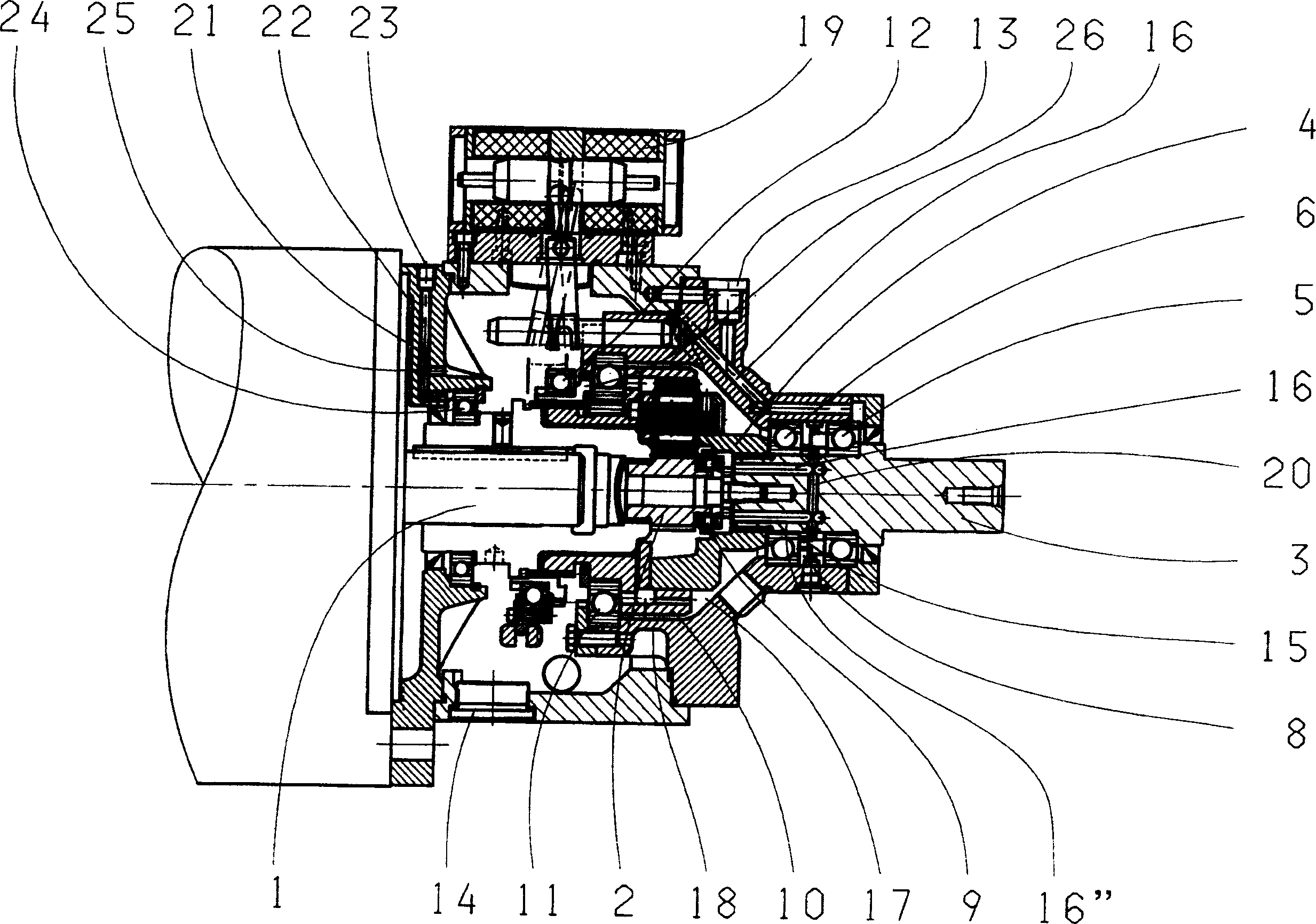

[0014] Since two-stage planetary gearboxes for machine tools are known to those skilled in the art, only the parts necessary for understanding the invention will be described below.

[0015] Use 1 to mark the transmission shaft 1 of the planetary gearbox, use 2 to mark the sun gear connected to it, use 3 to mark the driven shaft and use 4 to mark the planet carrier connected to it. 13 marks the oil inlet, which in the exemplary embodiment shown is located near the connection 19 of the sliding sleeve 11 in the bearing housing or in the gearbox housing. The oil inlet is connected to an oil pump (not shown) arranged outside the gearbox and is connected to the first outer bearing 5 of the driven shaft 3 via a pipeline 16 formed on the casing wall of the gearbox. The first outer bearing 5 is separated from the second inner bearing 6 by a piston ring 8 , wherein the piston ring 8 has channels. The channel can either be a small hole 15 formed parallel to the axis of the driven shaft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com