Method for the production of aluminum-containing honeycomb bodies with the aid of radiant heaters

A radiant heater, aluminum honeycomb technology, applied in the direction of manufacturing tools, metal processing equipment, welding equipment, etc., can solve the problems of uneven utilization of bonding technology, etc., to achieve the effect of ensuring compensation for expansion and uniform distribution of heat energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

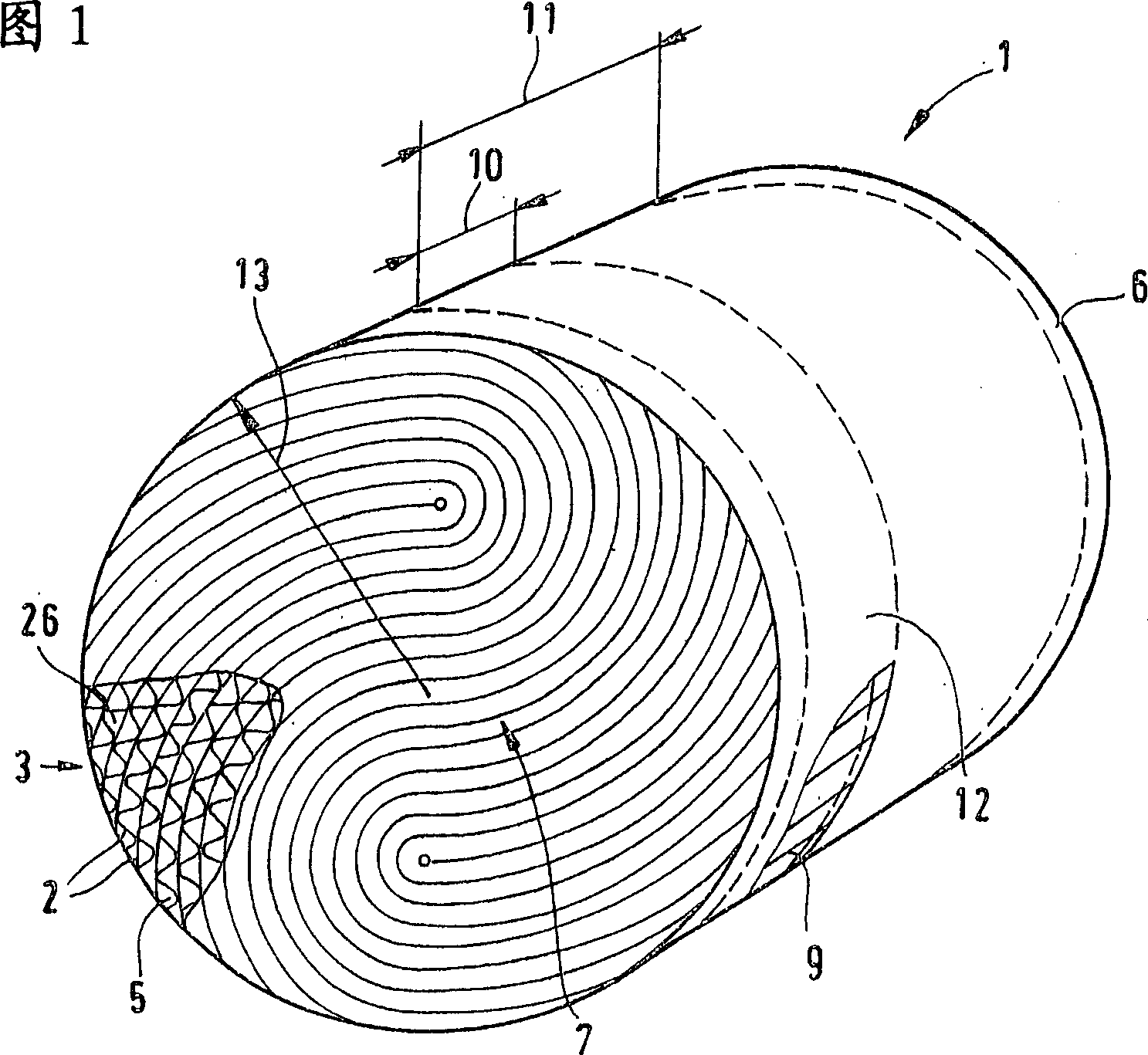

[0042] FIG. 1 shows a schematic perspective view of an aluminum-comprising honeycomb body 1 with laminated metal sheets 2 wound in an S-shape. The honeycomb body 1 has channels 5 formed using smooth and corrugated metal sheets 2 . The channels 5 and the metal foils 2 form a corresponding honeycomb structure 3 . The honeycomb structure 3 is surrounded by a tubular jacket 6 which protrudes beyond the end face 7 of the honeycomb body 1 . Here, the open end faces 26 of the individual channels 5 are arranged substantially within the flat end faces 7 of the honeycomb body 1 .

[0043] The production of the aluminum-comprising honeycomb body 1 shown includes, for example, the following steps:

[0044] - selection of at least partially structured aluminum-based foils;

[0045] - stacking and S-winding the at least partially structured metal sheets to form a honeycomb structure 3 with channels 5 extending substantially parallel to the axis 4 (not shown);

[0046] - inserting the me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com