Preparation method of 2-(4'-methyl benzene sulfonyl) ethyl propionate

A technology of methylbenzenesulfonic acid group and ethyl propionate, applied in the direction of organic chemistry, etc., can solve the problems of low recovery rate of triethylamine, slow reaction speed, large environmental pollution, etc., to reduce pollution and labor, improve The effect of reaction speed and production cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

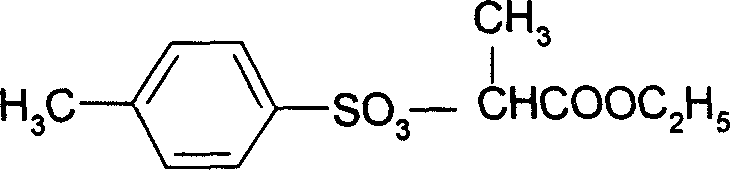

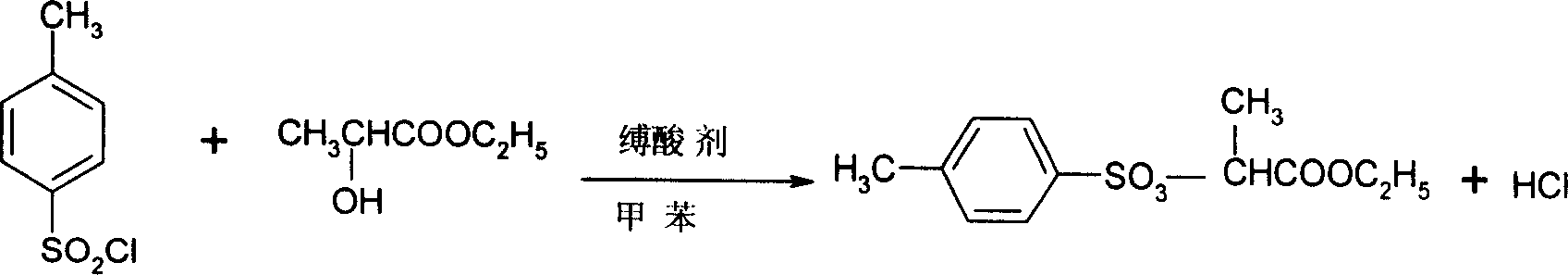

[0010] Put 870kg petroleum grade toluene and 435kg industrial grade sodium hydroxide (NaOH) or potassium carbonate (K 2 CO 3 ) or calcium oxide (CaO), turn on the cooling water to stir and drop in 250kg of p-toluenesulfonyl chloride with a content of 99.5%, and add 186kg of p-toluenesulfonyl chloride with a content of 99.5% to the reaction kettle dropwise below 10°C. For L-ethyl lactate, continue the insulation reaction for 2-5 hours after the dropwise addition, until the reaction residue of p-toluenesulfonyl chloride is basically zero. After the reaction is over, add 600kg of water to the system, stir and dissolve, then pass to the distillation pot, and keep Use industrial hydrochloric acid to adjust the pH value of the system to 6-7 at room temperature, and then distill the toluene under negative pressure after removing the lower layer of water. base) ethyl propionate. The content reaches 98%, and the yield is ≥97%. Its chemical formula is as follows:

[0011]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com