Method for testing real stress of self-compensating concrete structure and concrete real stress gauge

A technology of concrete structure and true stress, applied in the direction of material inspection products, etc., can solve the problem that concrete stress cannot be accurately tested.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] Embodiment 1 Self-compensating concrete structure true stress test method, the method comprises:

[0062] 1) According to the test requirements, determine the accuracy and range of the force sensor, and select a static or dynamic force sensor with good stability;

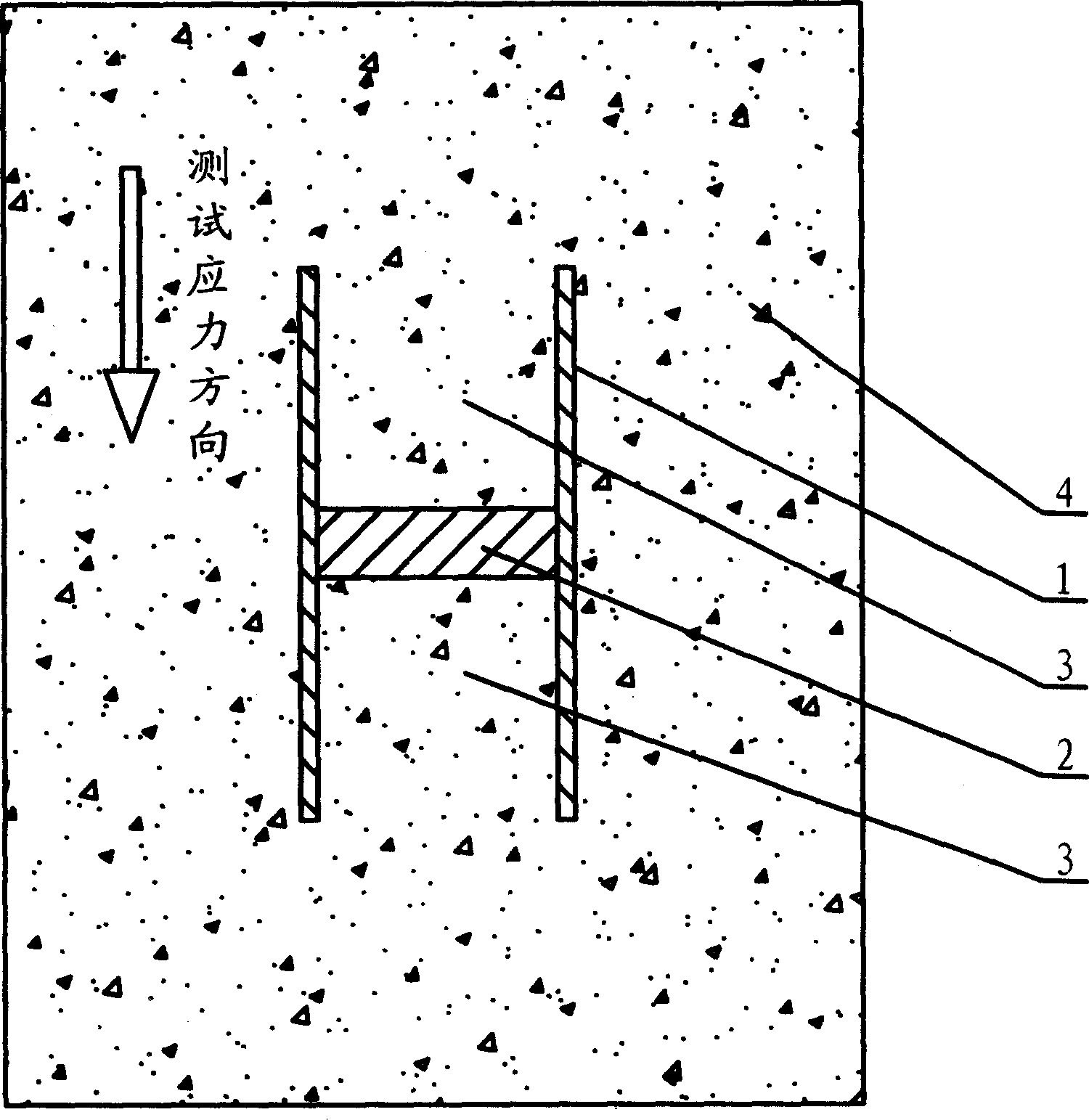

[0063] 2) Make or install a suitable isolation device, the length of the isolation device should not be less than 10 times the thickness of the force sensor;

[0064] 3) Fix the force sensor inside or at the end of the isolation device to form a concrete real stress gauge, and record the cross-sectional area inside the isolation device;

[0065] 4) Before concrete pouring, place a real concrete stress gauge along the test direction at the part where the stress needs to be tested, and lead the data line or power line out of the formwork;

[0066] 5) Pouring concrete and vibrating it near the real stress gauge of the concrete to ensure that the concrete inside and outside the isolation device is evenly dense; ...

Embodiment 2

[0068] Embodiment 2 Concrete True Stress Meter

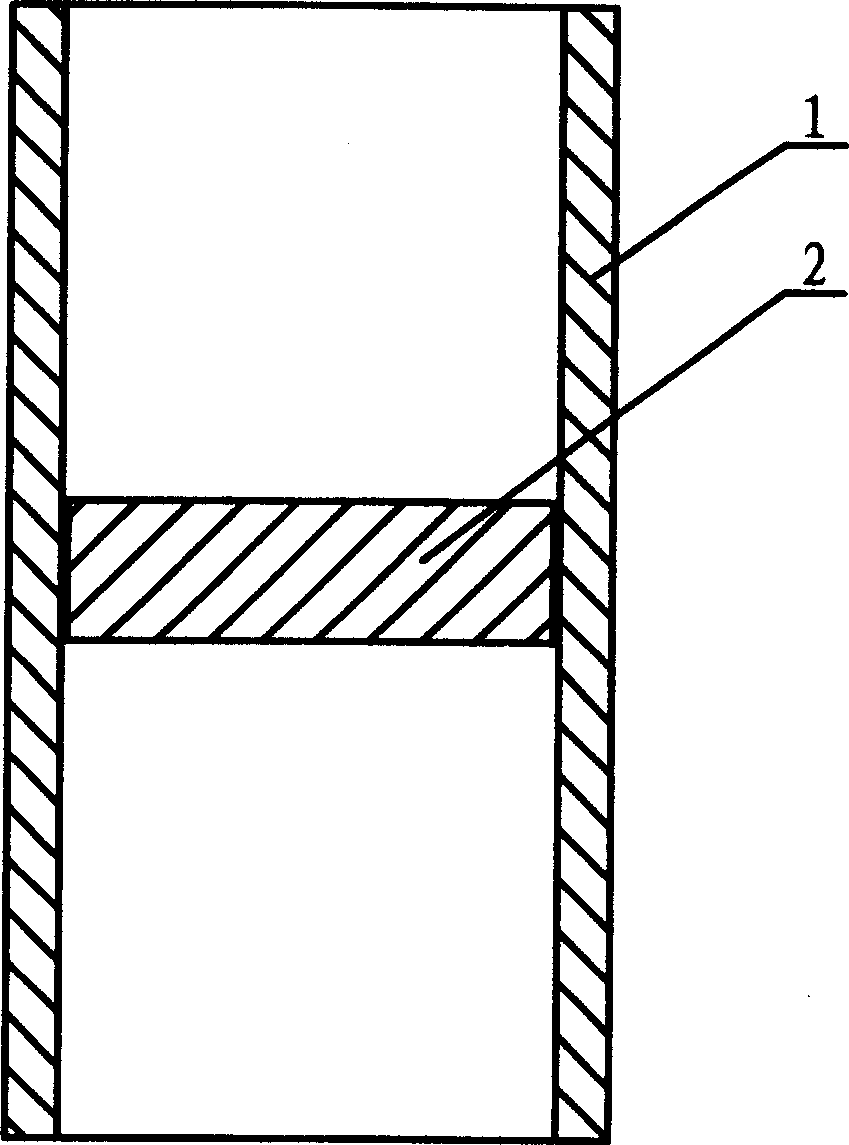

[0069] see figure 1 , figure 1 It is a structural schematic diagram of an embodiment of the concrete real stress gauge of the present invention. It can be seen from the figure that the concrete real stress gauge made by the present invention includes an isolation device 1 and a force sensor 2, and has a simple structure and is convenient for application. Place the force sensor 2 inside the isolation device 1 and fix it. The force sensor is a pie-shaped structure whose cross section matches the cross section of the isolation device. When the force sensor is located at a certain part in the middle of the isolation device, the concrete in the isolation device is divided into two parts by the force sensor; when the force sensor is located at the end of the isolation device, the internal concrete is a whole.

[0070] The force sensor of the present invention can directly use commercially available vibrating wire pressure cells, pie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com