Distance scale mounting mechanics for holographic aiming device and mounting method thereof

A distance scale and setting mechanism technology, which is applied in the field of weapon aiming equipment, can solve the problems of large volume and weight, poor stability, etc., and achieve the effect of fast distance scale and fast setting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

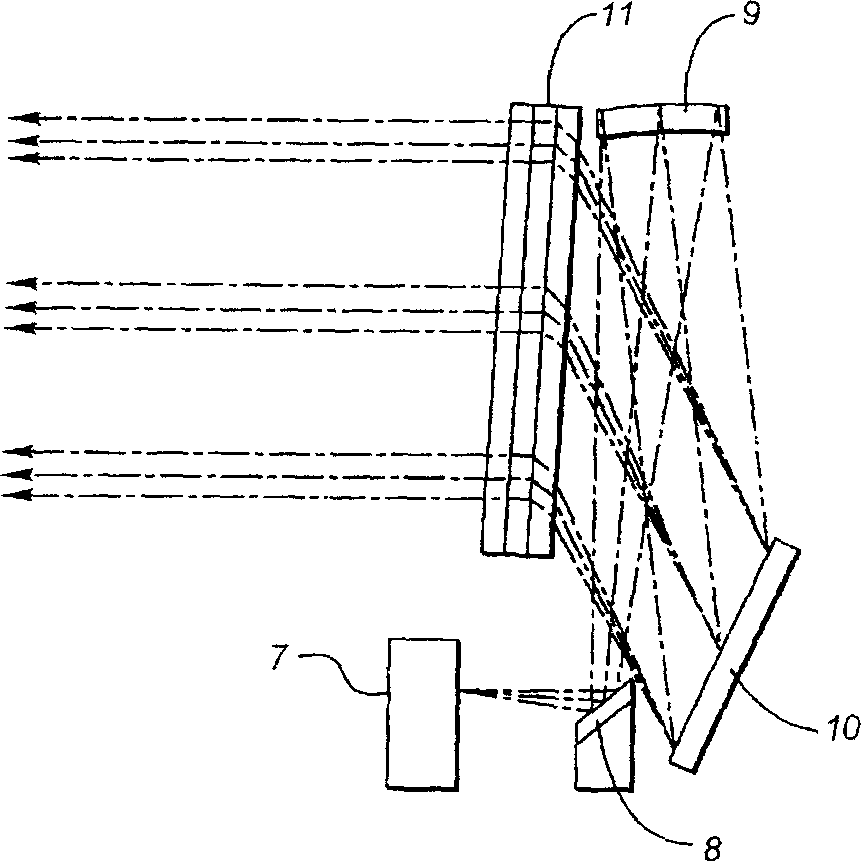

[0023] like Figure 3-8 As shown: the laser 12 of the holographic collimator is located at the focal point of an optical collimator 14, and after being refracted or reflected by the collimator 14, the laser beam emitted by the laser 12 becomes a parallel beam. The parallel laser beam shoots to the diffraction grating 15 at a certain angle, and the output is still a parallel light at a certain angle. The setting of the distance scale is actually to change the direction of the beam of light emitted from the hologram 16. The present invention provides two methods for changing the direction of the beam of light emitted from the hologram 16 when the positions of the hologram 16 and the diffraction grating 15 remain unchanged: (1) Two or more lasers with different wavelengths are used for illumination respectively, and the directions of the outgoing light beams of the diffraction grating 15 and the hologram 16 will change, and the purpose of labeling can be achieved by properly sele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com