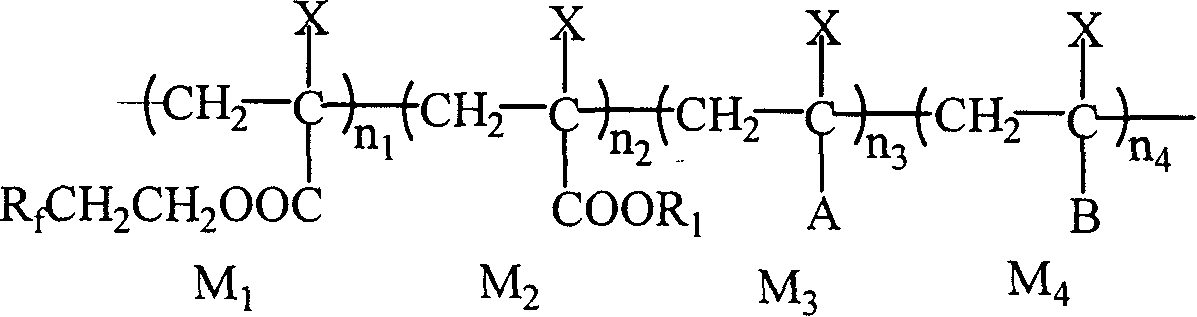

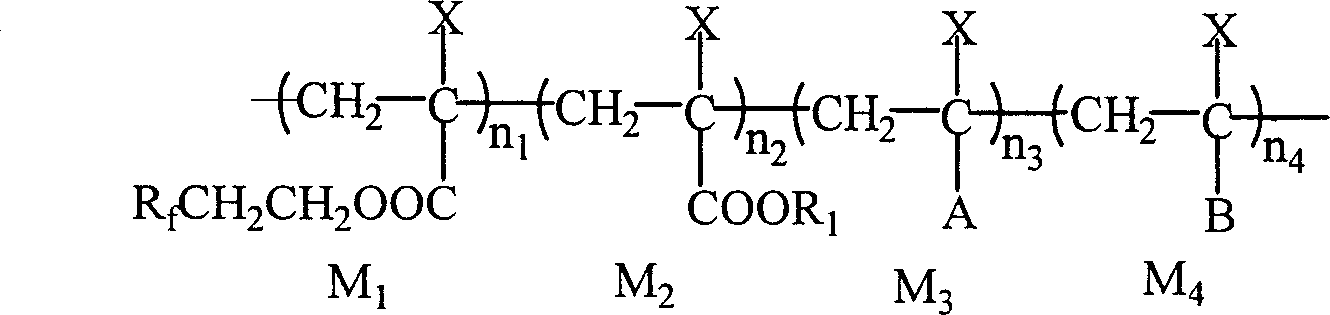

Low fluorine content material and synthesizing process thereof

A synthesis method and technology of fluorine content, applied in the field of surface treatment and protection materials, can solve the problems of expensive waterproofing agent, high price, large proportion of fluorine-containing monomers, etc., to reduce fluorine content, reduce production costs, Environmentally friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] At room temperature, mix 18 parts of methyl methacrylate, 12 parts of butyl methacrylate, 15 parts of octadecyl methacrylate, 12 parts of dodecafluoroheptyl methacrylate, 2 parts of N-methylolpropene Acyl, 1 part of styrene, 2 parts of sodium lauryl sulfate, 0.5 part of n-dodecyl mercaptan, and 100 parts of deionized water are added to the reactor; install the condenser, nitrogen conduit, stirrer, thermometer, and heater , pre-emulsified for 1 hour; blow nitrogen and heat up to 85°C, add 0.5 parts (NH 4 ) 2 S 2 o 8 , heat preservation reaction for 4 hours; finally cooled to room temperature to obtain a flowable O / W type polymer emulsion which is the fluorine-containing material described in the present invention, its solid content is about 38.5%, and the consumption of fluorine-containing monomer is 19.2%. The results of various performance measurements are shown in Table 1.

Embodiment 2

[0030] Initiator with 0.003mol NaHSO 3 ~(NH 4 ) 2 S 2 o 8 (molar ratio 1: 1) instead, the heat preservation reaction temperature is 30 ℃, and the reaction time is 2 hours, and other raw material consumption and operation steps are identical with embodiment 1. The results of various performance measurements are shown in Table 1.

Embodiment 3

[0032] The emulsifier in Example 1 is changed to 1 part of sodium lauryl sulfate and 1 part of OP-10, and the amount of other raw materials, reaction conditions and operating steps are the same as in Example 1. The results of various performance measurements are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com