Accumulator control device and method for micro gas turbine

A micro gas turbine and control device technology, applied in battery circuit devices, circuit devices, adaptive control, etc., can solve the problems of battery dehydration, battery permanent damage, low charging efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

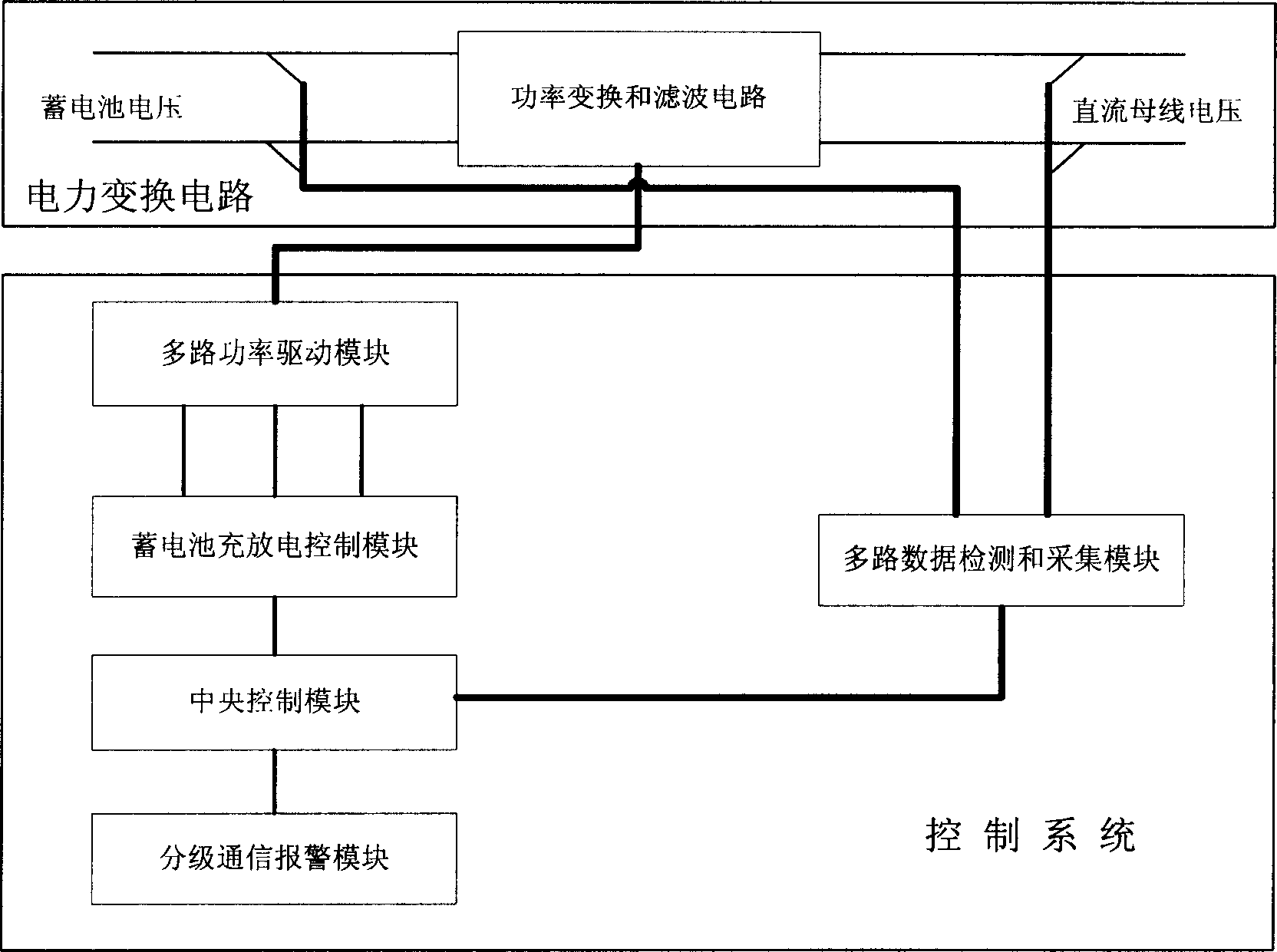

[0158] The device of the present invention is composed of two parts, a power conversion circuit and a control system, such as figure 1 shown. The power conversion circuit is a power conversion and filtering circuit; the control system includes a multi-channel power drive module, a multi-channel data detection and acquisition module, a central control module, a hierarchical communication alarm module, and a battery charge and discharge control module.

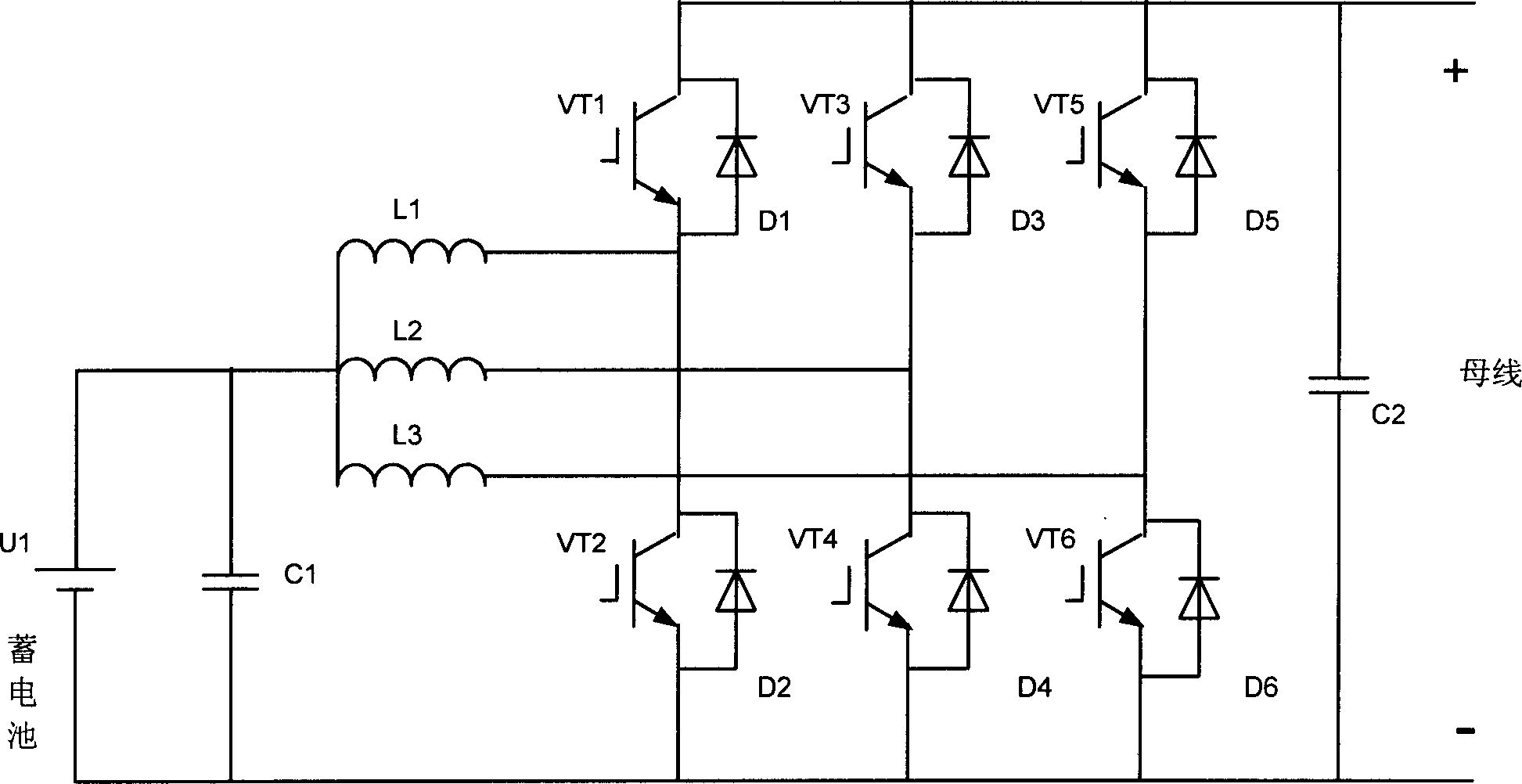

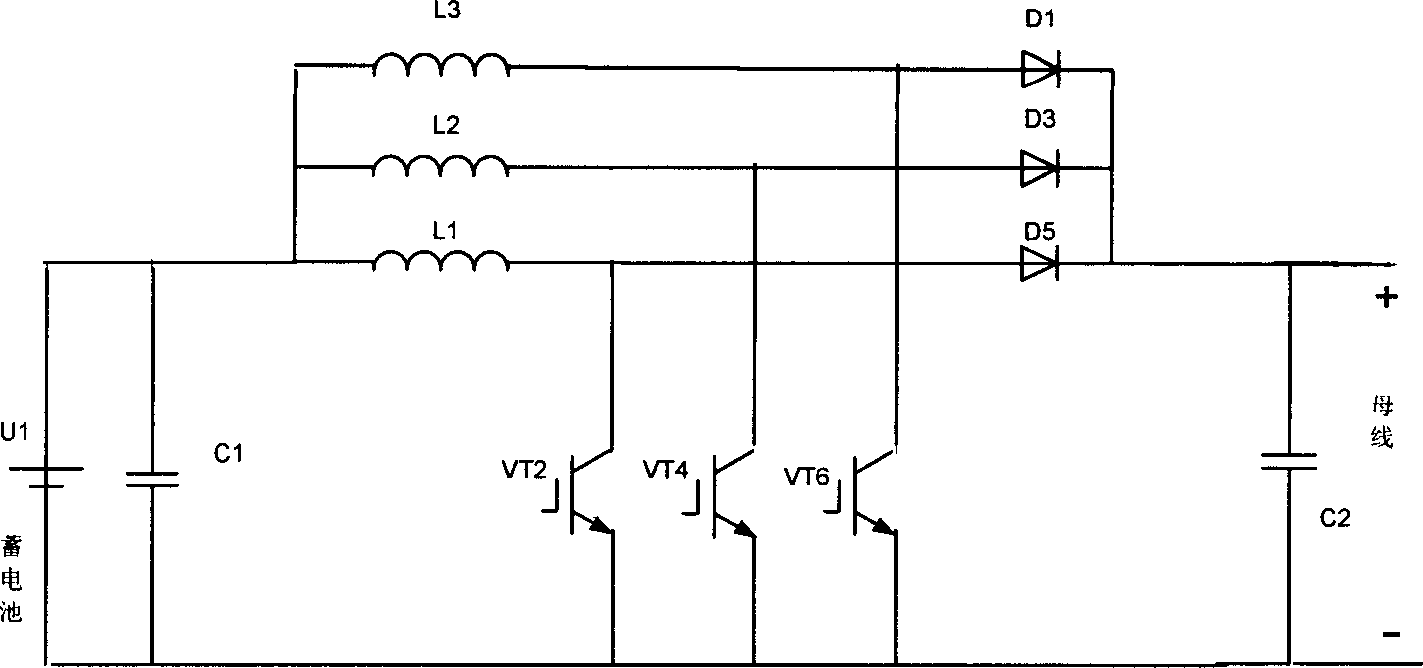

[0159] The power conversion and filter circuit is composed of six IGBTs, six freewheeling diodes, three inductors and two capacitors, and adopts a parallel and interleaved structure of three bridge arms, such as figure 2 shown. In the figure, a DC voltage is applied between the positive and negative voltages, and every two IGBTs and every two diodes connected between the positive and negative voltages form a unit (ie, a bridge arm) which is realized by a dual IGBT module, and an inductor is connected to each module .

[0160...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com