Semi-dry method of washing machine and the ventilating structure, control apparatus for the same

A control device and semi-drying technology, applied in the field of washing machines, can solve the problems of increasing the manufacturing cost of washing machines, increasing energy consumption, clothes odor, etc., and achieving the effects of shortening the required time, reducing power consumption, and eliminating peculiar smells

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

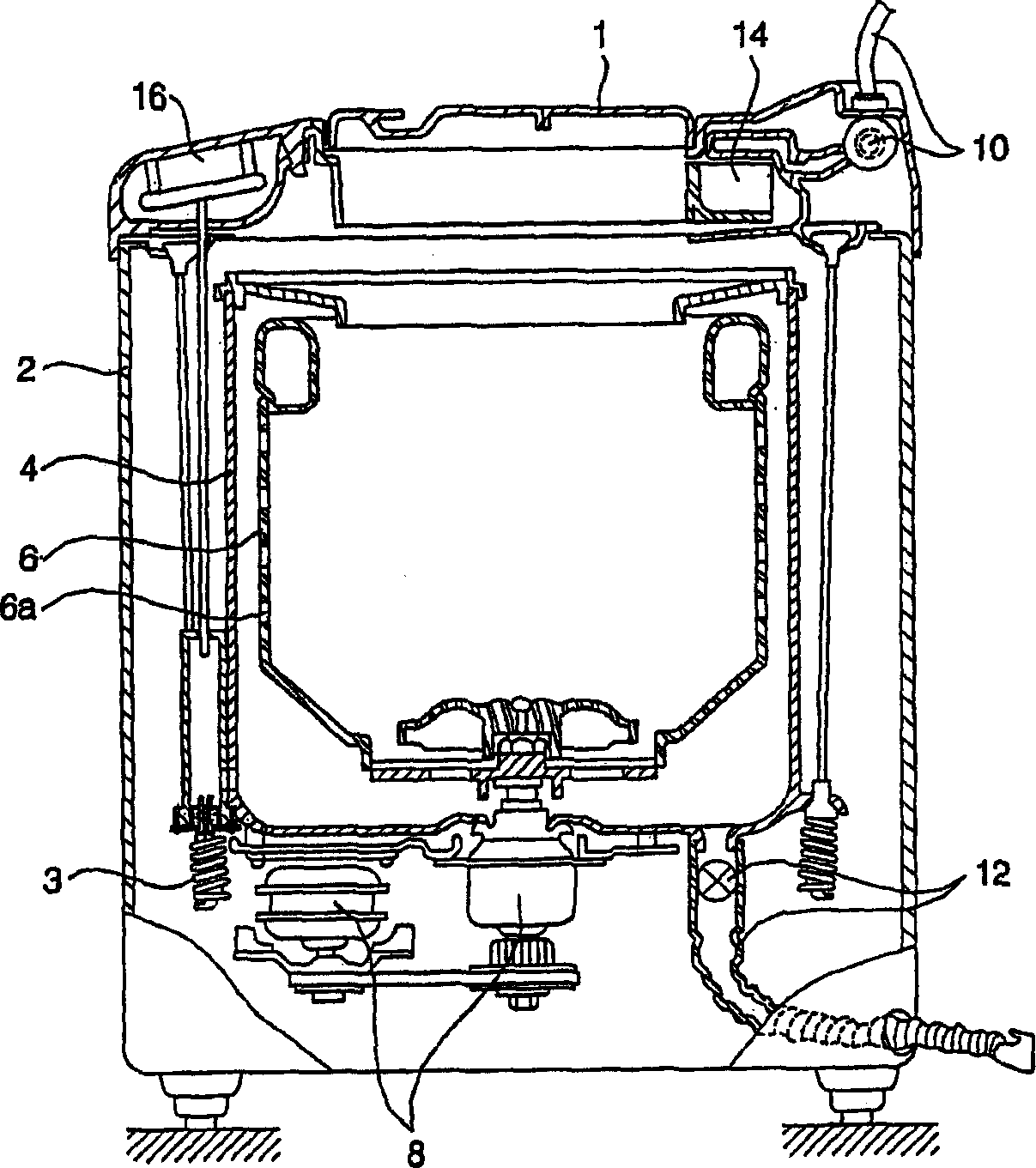

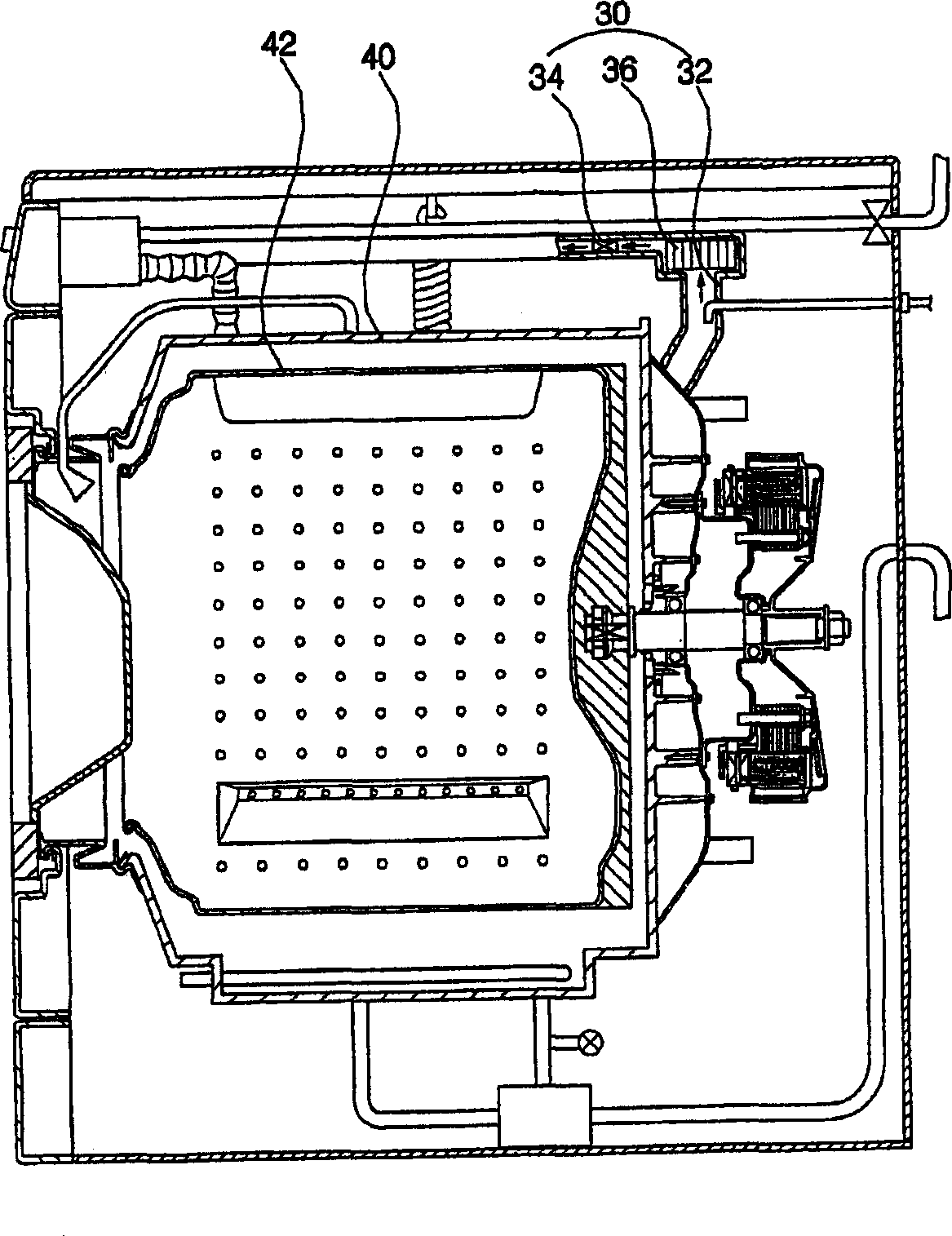

[0072] Preferred embodiments of the present invention will now be described in detail with reference to the accompanying drawings.

[0073] First, the washing machine implementing the semi-drying method of the present invention performs a washing operation for removing stains from laundry, a rinsing operation for rinsing laundry with clean washing water, and spins a washing tub for a short time to dehydrate wet laundry using centrifugal force. The spin-drying operation, and the semi-drying operation in which the clothes are dehydrated at a higher degree of dehydration than the clothes are dehydrated by centrifugal force. Therefore, when the laundry is dehydrated, the spin-drying operation and the semi-drying operation may be selectively performed according to a user's selection.

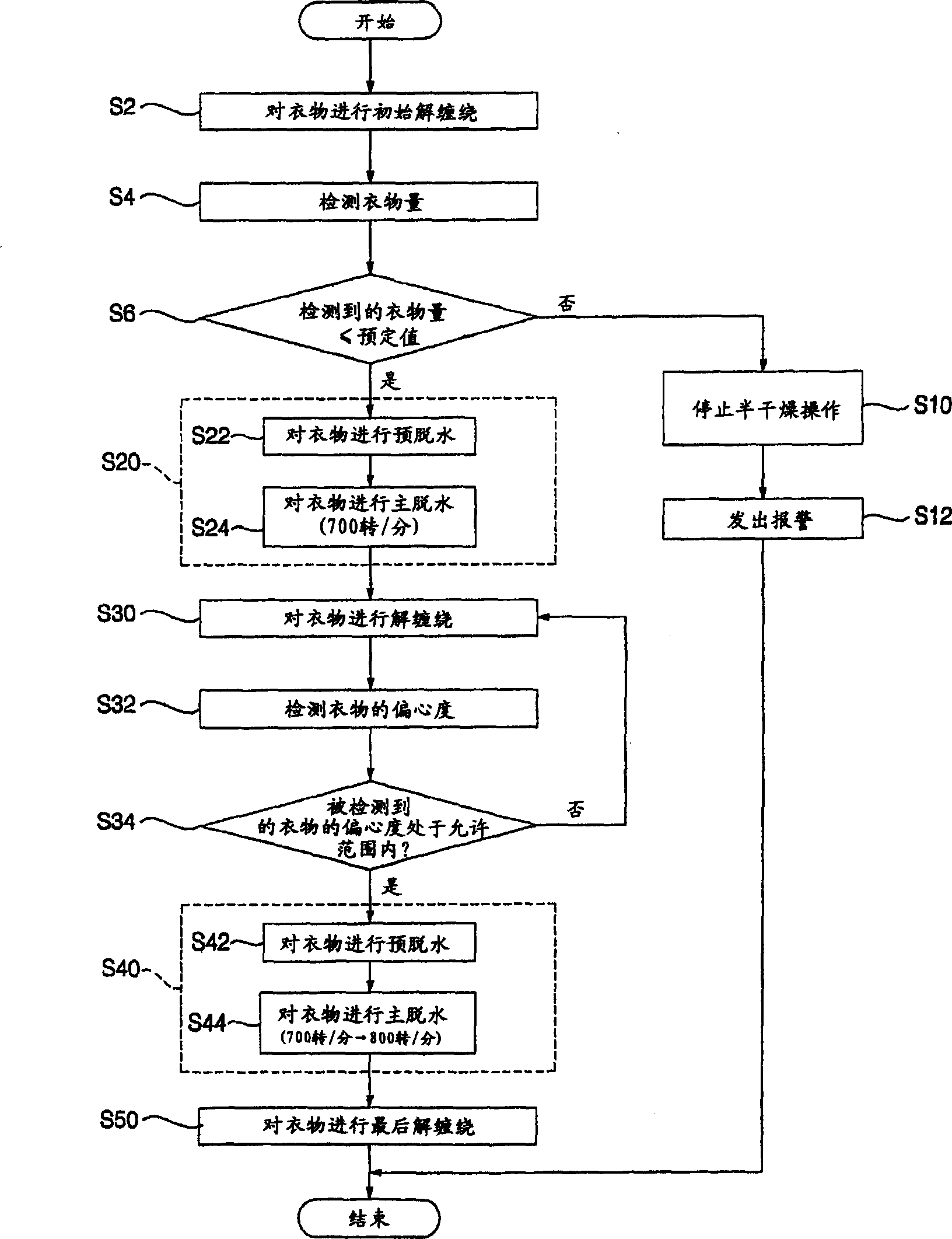

[0074] image 3 It is a flowchart of the semi-drying method of the washing machine which concerns on one Embodiment of this invention.

[0075] Refer below image 3 The semi-drying operation of on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com