Optical lens, light emitting device package using the optical lens, and backlight unit

A technology of optical lenses and light-emitting devices, applied in the field of optical lenses, can solve the problems of increased display panels, complicated assembly process, incorrect arrangement, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

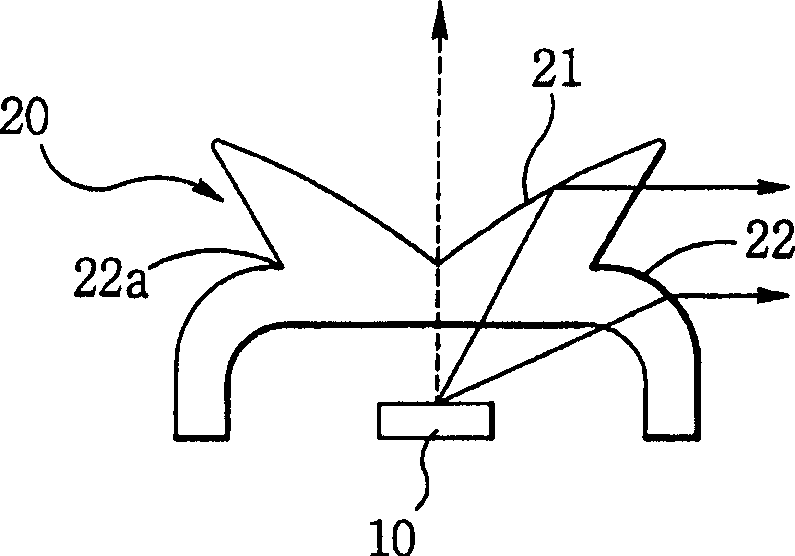

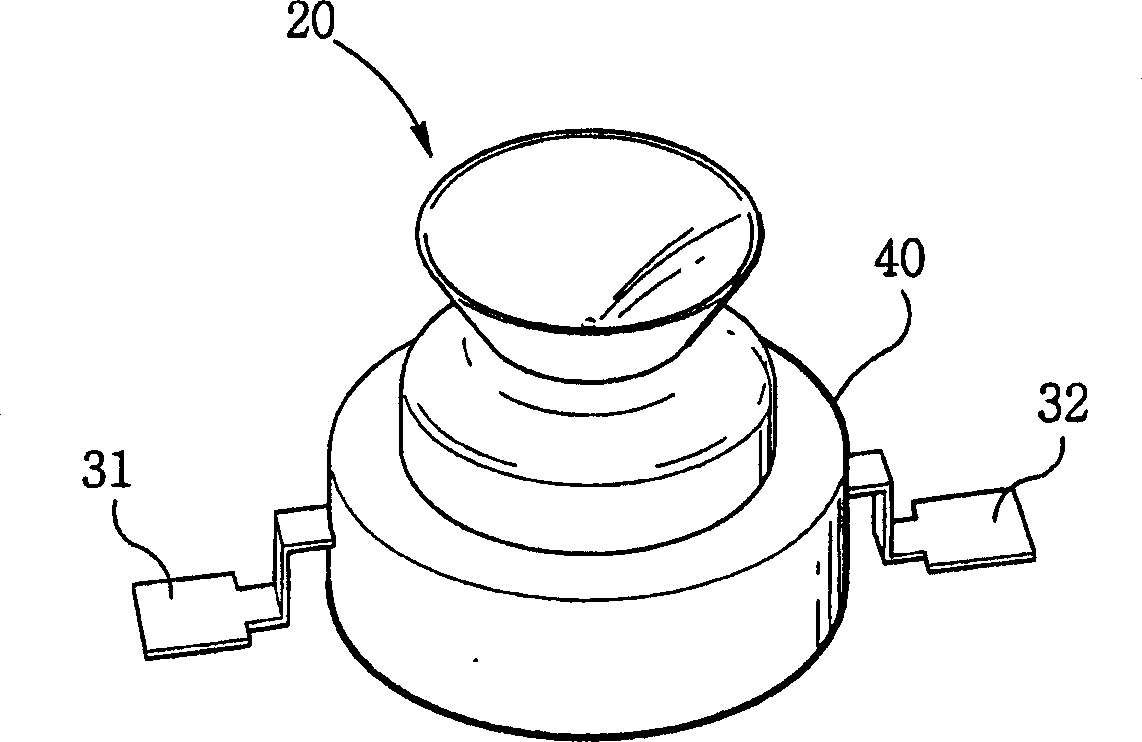

[0044] See Figure 7 , The optical lens 200 according to the first embodiment of the present invention includes: a reflective surface 210 formed thereon for reflecting light emitted upward from the light emitting device; and a bottom refraction surface 220 for refracting light emitted upward from the light emitting device And allow the light to reach the reflective surface 210, wherein the path of the light incident from below is changed to reach the side of the optical lens 200.

[0045] Meanwhile, the optical lens 200 includes a body. The body has a reflective surface 210 formed thereon, and is also formed with a bottom refraction surface 220 from which light incident thereunder is refracted and emitted.

[0046]The light incident on the reflective surface 210 is emitted from the bottom of the main body to the upper part of the main body, and the light incident from the bottom of the main body is composed of light refracted and emitted above the main body and light emitted to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com