Material balance intelligent control system

A technology of intelligent control system and material balance, applied in general control system, control/regulation system, ratio control, etc., can solve the problems of difficult online operation of the model, large time lag, affecting the change of air permeability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

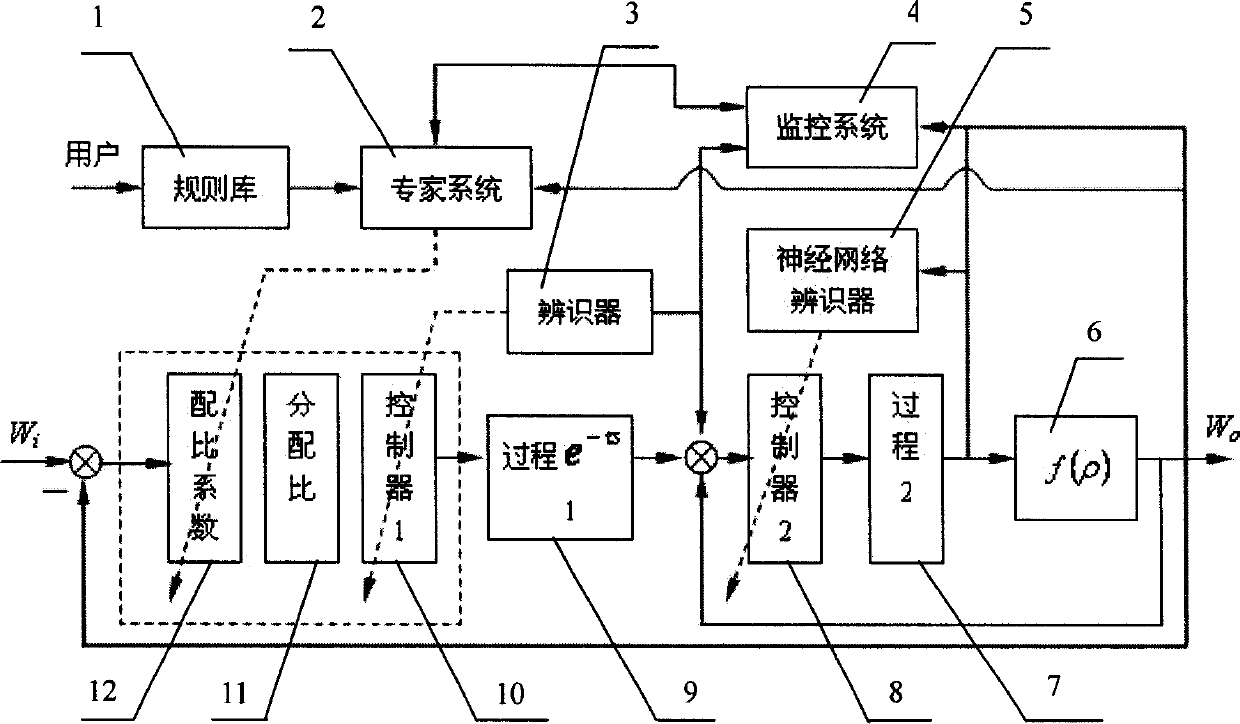

[0096] A major feature of material balance systems is hysteresis. Due to the existence of hysteresis, the difficulty of automatic control increases. In the actual situation that the lag of 16 minutes is much greater than the adjustable amount of 3 minutes, the present invention adopts the combination of classical control and fuzzy control, and consists of rule base 1, expert system 2, discriminator 3, monitoring system 4, and neural network. Recognizer 5, transfer function f(ρ)6 of the mixed material ore bin, process II7, controller II8, process e -τs I9, controller I10, distribution ratio 11 and ratio coefficient 12, among which, classical control realizes automatic batching and sequential control of 80 electrical equipment; fuzzy control forms corresponding membership functions and control rules based on operator experience, control rules and membership functions It can be adaptively optimized according to the dynamic changes of the process.

[0097] The control strategy o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com