Thin-wall metal pipe quick-locking connection structure

A technology for metal pipe fittings and connecting structures, which is applied in the field of quick-locking connection structures of thin-walled metal pipe fittings. Good performance and high compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

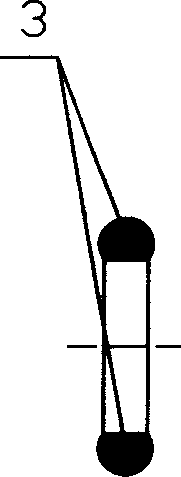

[0039] Such as Figure 6 with Figure 7 As shown, a quick-locking connection structure for thin-walled stainless steel pipe fittings includes a thin-walled stainless steel pipe fitting 1, a thin-walled stainless steel pipe body 2, a sealing ring 3, a stainless steel outer compression nut 10 and a sealing ring for pressing 3 thin-walled stainless steel top pressure ring 9;

[0040] Such as figure 1 , Figure 8 with Picture 9 As shown, the inner wall of the connecting end of the thin-walled stainless steel pipe fitting 1 is successively provided with stepped holes 4 in the pipe body for inserting the thin-walled stainless steel pipe body 2, the convex ring groove 5 for setting the sealing ring 3, and the To insert a stepped hole 6 in the top pressure ring 9 of the top pressure ring 9, the outer side of the connecting end of the thin-walled stainless steel pipe fitting 1 is provided with a threaded external interface 7;

[0041] Such as figure 2 with Picture 12 As shown, the seali...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com