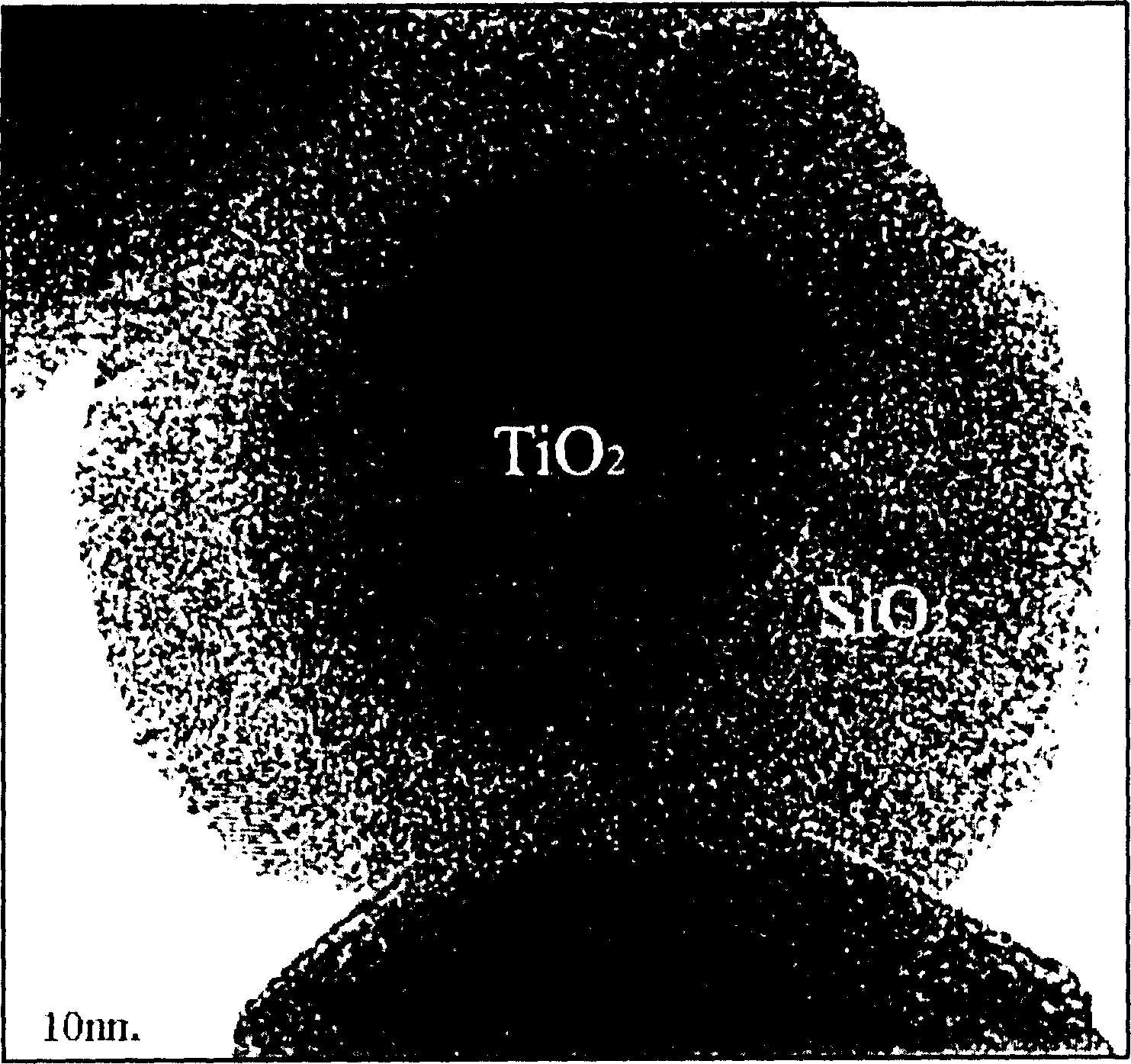

Method and equipment for preparing nucleocapsid type TiO2/SiO2 nano composite granule

A nano-composite and particle technology, applied in the direction of silicon dioxide, titanium oxide/hydroxide, titanium dioxide, etc., to achieve the effects of easy industrial production, convenient operation, and simple equipment structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

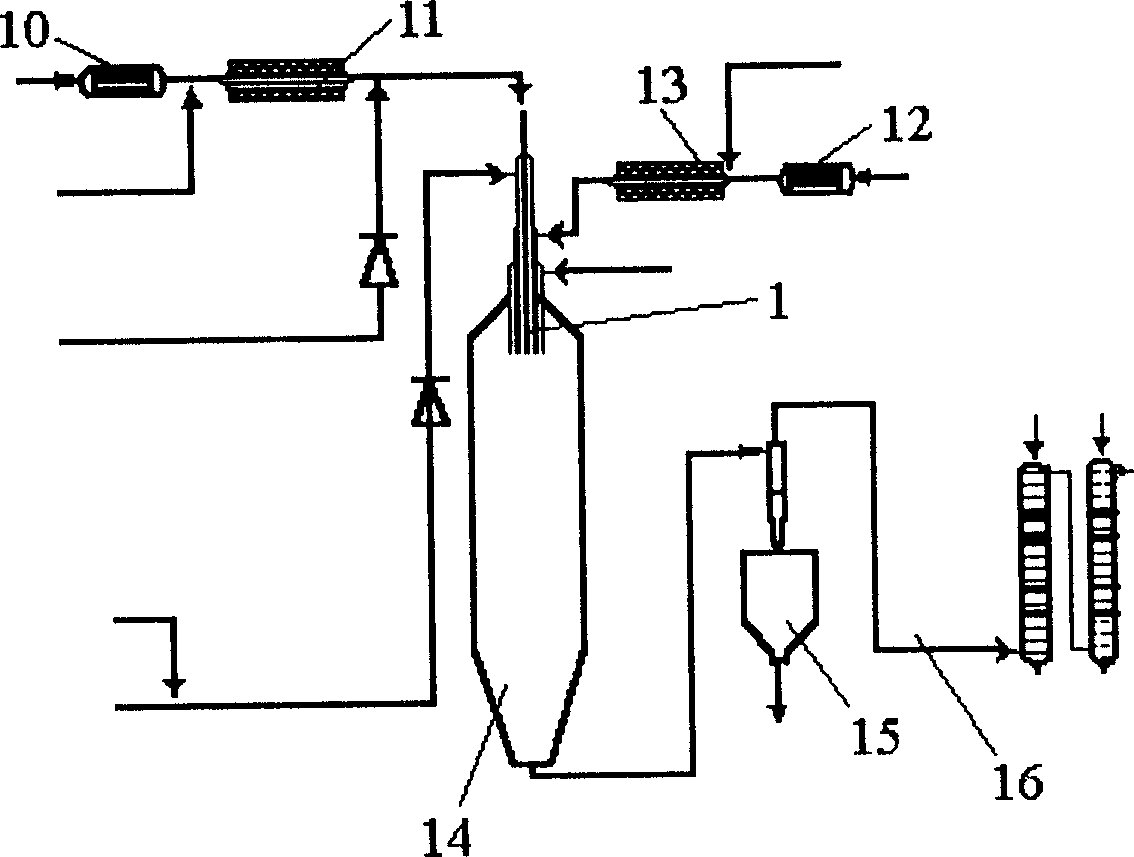

[0042] Device parameters:

[0043] The height of said combustion reactor 15 is 0.3 meters, and its diameter is 0.05 meters;

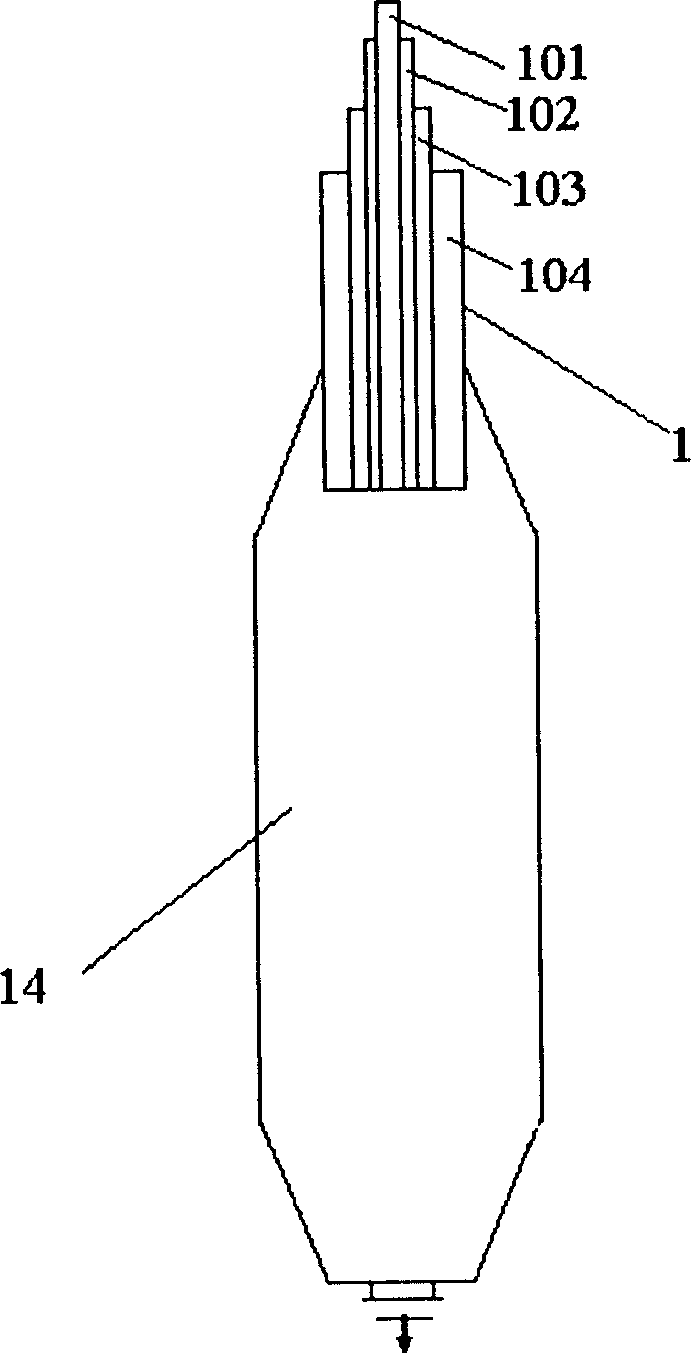

[0044] The flow cross-sectional area of the central tube 101 is 12mm 2 , the flow cross-sectional area of the second ring pipe 102 is 22m 2 ,, the flow cross-sectional area of the three-ring pipe 103 is 34mm 2 The flow cross-sectional area of the four-ring pipe 104 is 100mm 2

[0045]Titanium tetrachloride (1.2L / h) was evaporated at 120°C with air (3m 3 / h) mixed, preheated to 100 ℃ and hydrogen (1.0m 3 / h) mix and pass into central tube 101;

[0046] Into the second ring pipeline into the air (0.6m 3 / h) and hydrogen (0.6m 3 / h) mixed gas at a temperature of 50°C;

[0047] Air (6m 3 / h) preheated to 70°C by the second preheater 12, silicon tetrachloride (1.2L / h) evaporated at 70°C, mixed and passed into the three-loop pipe 103;

[0048] Air is introduced into the four-ring pipe (10m 3 / h), the temperature is 80°C;

[0049] Under th...

Embodiment 2

[0053] The height of said combustion reactor 15 is 2.5 meters, and its diameter is 0.4 meters;

[0054] The flow cross-sectional area of the central tube 101 is 220mm 2 , the flow cross-sectional area of the second ring pipe 102 is 130mm 2 ,, the flow cross-sectional area of the three-ring pipe 103 is 260mm 2 , the flow cross-sectional area of the four-ring pipe 104 is 600m 2 ;

[0055] Titanium tetrachloride (40L / h) was evaporated at 250°C, and air (30m 3 / h) mixed, preheated to 200 ° C and hydrogen (12m 3 / h) mix and pass into central tube 101;

[0056] Into the second ring pipeline into the air (10m 3 / h) and hydrogen (7m 3 / h) mixed gas at a temperature of 50°C;

[0057] Air (20m 3 / h) preheated to 200°C by the second preheater 12, silicon tetrachloride (20L / h) evaporated at 200°C, mixed and passed into the three-ring pipe 103;

[0058] Air is introduced into the four-ring pipe (100m 3 / h) The temperature is 20°C;

[0059] Under the condition that the r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com