Reversible electrochemical sensors for polyions

A polyion, electrochemical technology, applied in the direction of material electrochemical variables, scientific instruments, instruments, etc., can solve problems such as increased cost, time-consuming, and rapid loss of sensor response.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0138] Preparation of protamine-selective membranes

[0139] The ability of the sensor incorporating the polyion selective membrane according to the invention to be used in an electrochemical cell was tested. The polycation selective membrane is specifically formulated to be selective for the polycation protamine. Membranes were formulated using 10 wt% TDDA-DNNS in a 2:1 weight ratio mixture of 2-nitrophenyloctyl ether and polyvinyl chloride. Membranes were prepared by means of solvent casting using THF as solvent. The mixture was dried to form a film, and a protamine-selective film of about 200 μm thickness was prepared. The film was cut with a drill having a diameter of 6 mm to prepare a film for incorporation into an electrode.

Embodiment 2

[0141] Preparation of protamine-selective membrane electrode

[0142] The protamine-selective membrane prepared in Example 1 was introduced into the electrode. Electrodes include Philips electrode body (IS-561), internal reference solution of 0.1M NaCl and electrode wire of Ag / AgCl. Protamine-selective membrane electrodes were conditioned overnight in the same solution as the internal reference solution before use in experiments.

[0143] A set of 10 identical electrodes were prepared as described above and tested for consistency in 0.1M NaCl solution before actual experimental use. Testing showed a variability of + / - 7 mV (standard deviation) between the electrodes at a given current between 0 and -10 μA from each other.

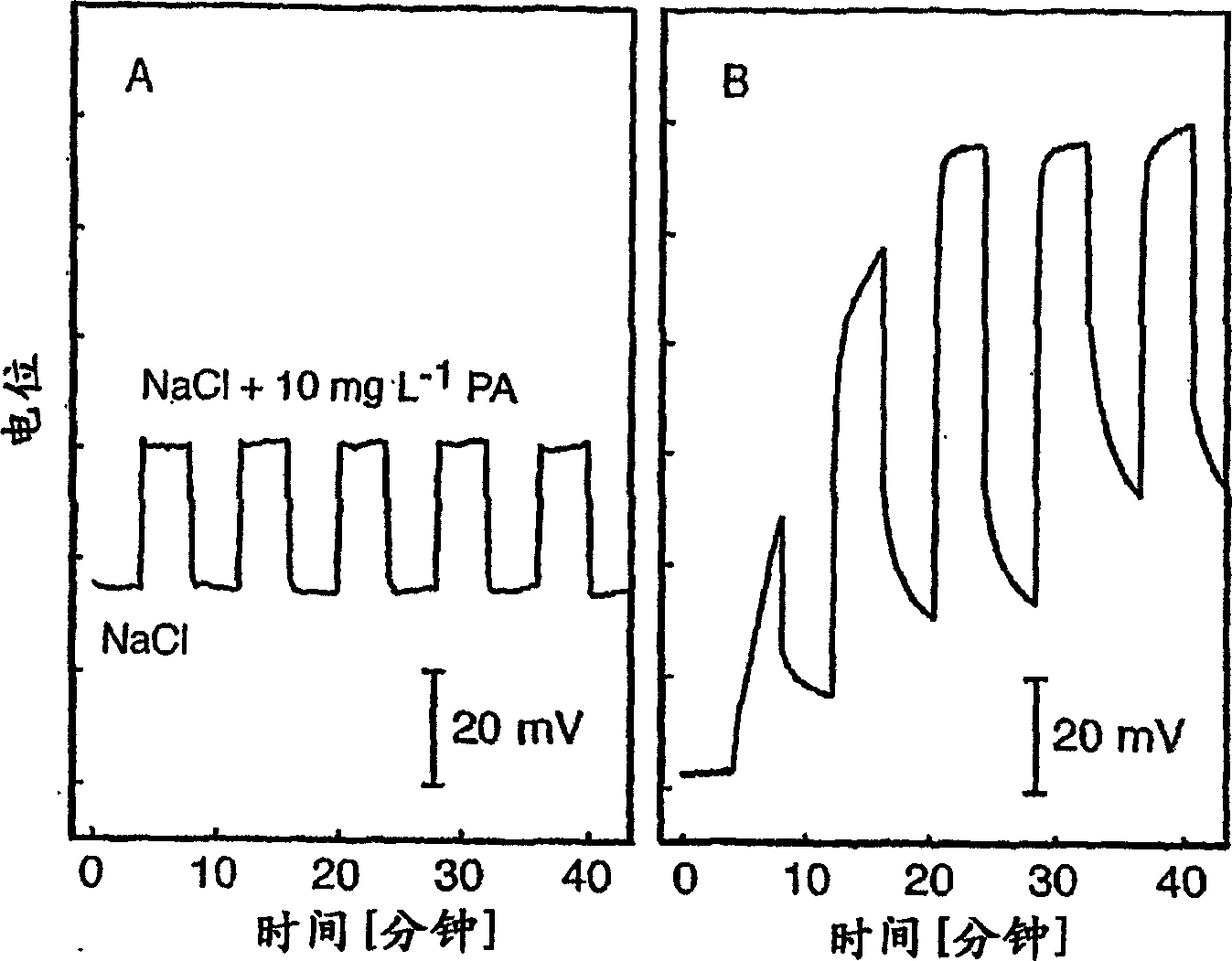

[0144] Membrane electrodes were also tested to evaluate reversibility. The membranes were repeatedly exposed to two separate solutions, one containing 0.1 M NaCl, and one containing 0.1 M NaCl and 10 mg / L protamine. The same experiment was al...

Embodiment 3

[0146] Chronopotentiometry response of samples

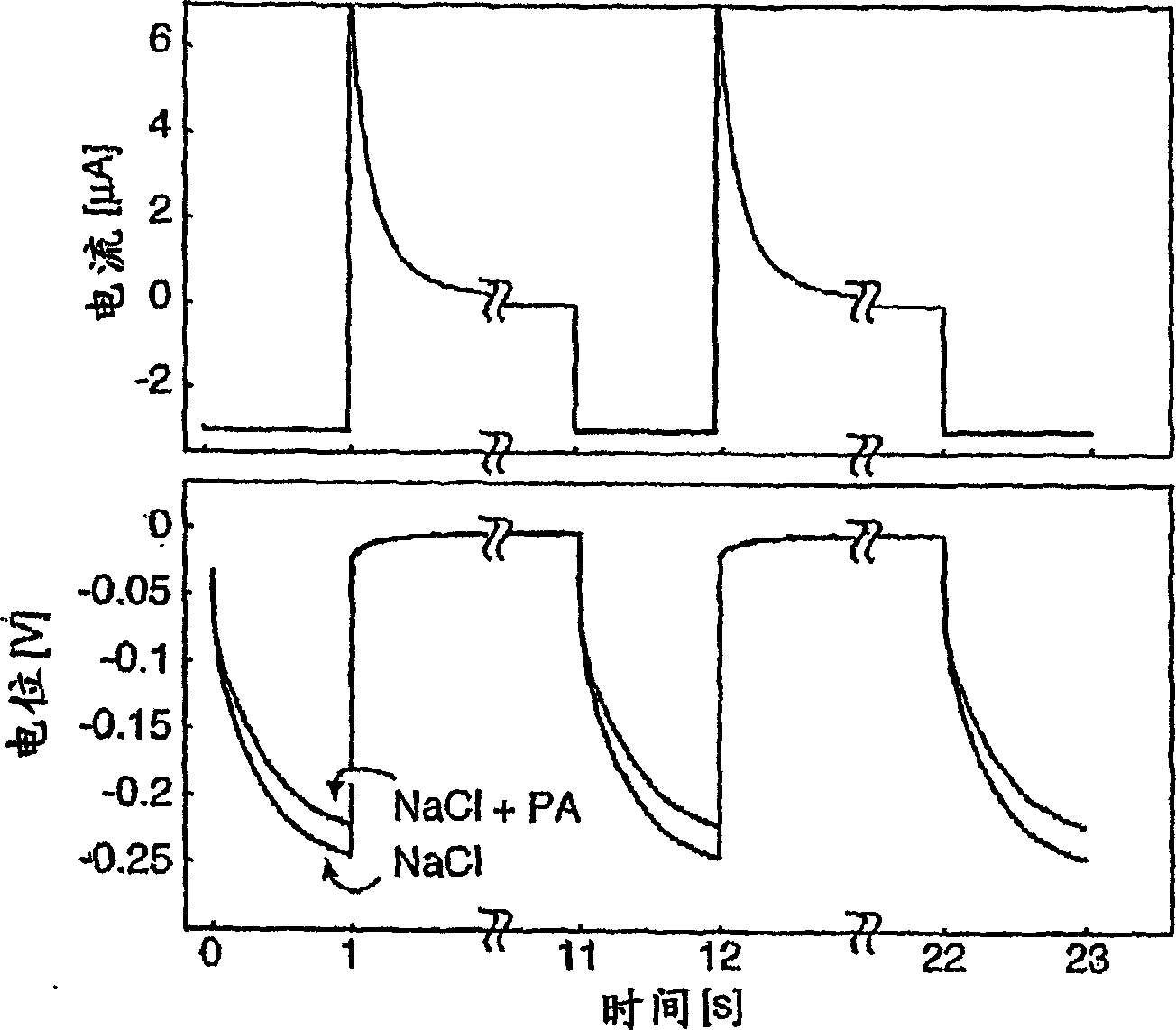

[0147] With and Without Protamine

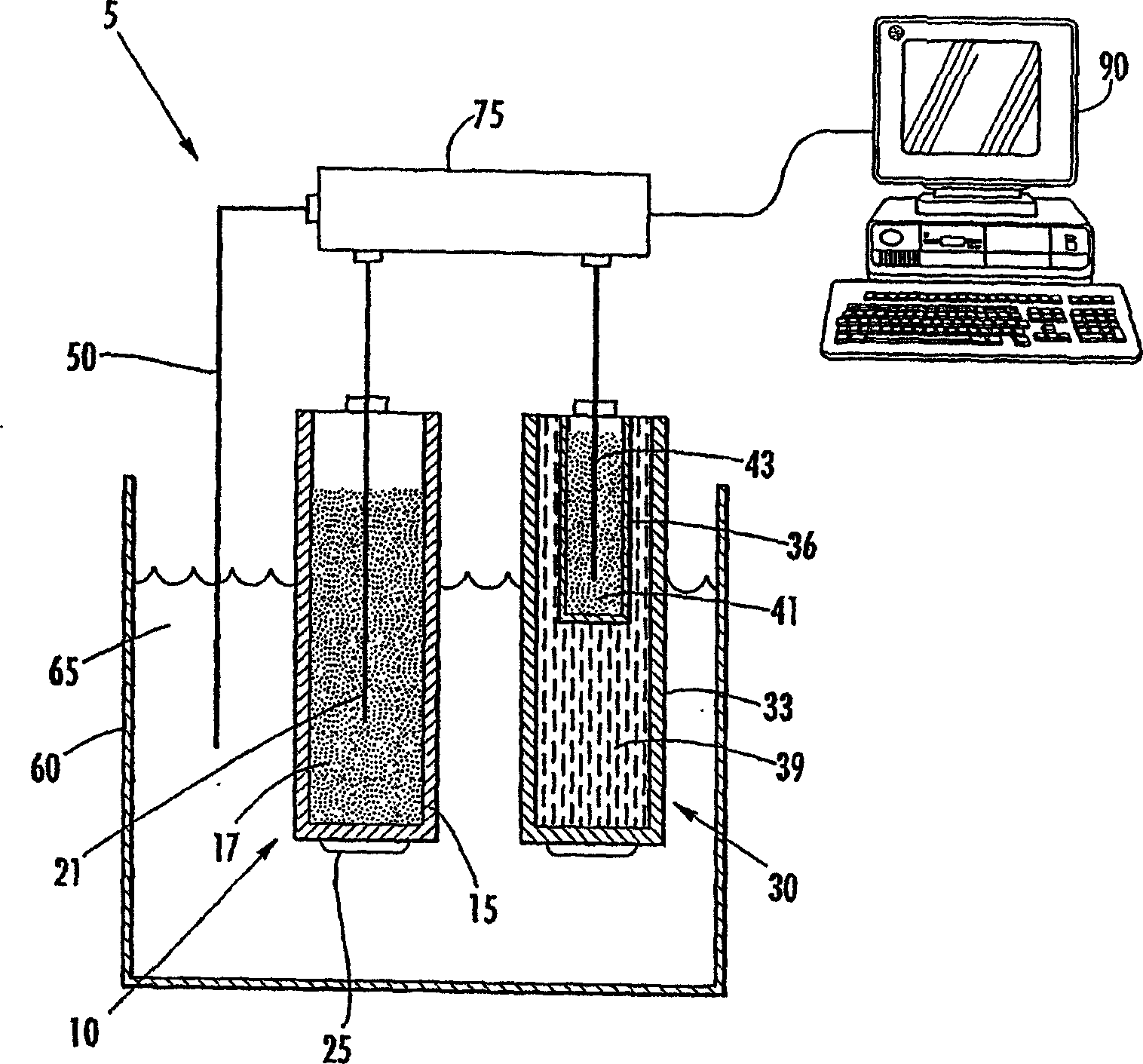

[0148] Chronopotentograms were made in 0.1 M NaCl with and without protamine. Electrochemical cells (such as in figure 1shown in ), installed by using the protamine-selective membrane electrode described in Example 2. The reference electrode was a double salt bridge Ag / AgCl electrode with 1M LiOAc bridge electrolyte. The counter electrode is a platinum wire.

[0149] Voltammetry experiments were performed using an AFCBP1 Bipotentiostat (Pine Inst., Grove City, PA) controlled by a PCI-MIO-16E4 interface board and LabVIEW 5.0 software (National Instruments, Austin, TX) on a Macintosh computer. Before the experiment, the operation of the output of the first electrode of the bipotentiostat (K1) was switched to current control using the potentiostatic control of the output of the second working electrode (K2). To apply current pulses, the working electrode was co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com