Gas-fired warmer with dual gas sources

A dual gas source and heater technology, applied to gas fuel burners, burners, combustion methods, etc., can solve problems such as backlog, increased user investment, waste of social resources, etc., to expand the scope of gas use, save repeated investment, The effect of convenient shopping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following structural drawings and embodiments further illustrate the present invention.

[0026] Such as Figure 1-7 shown.

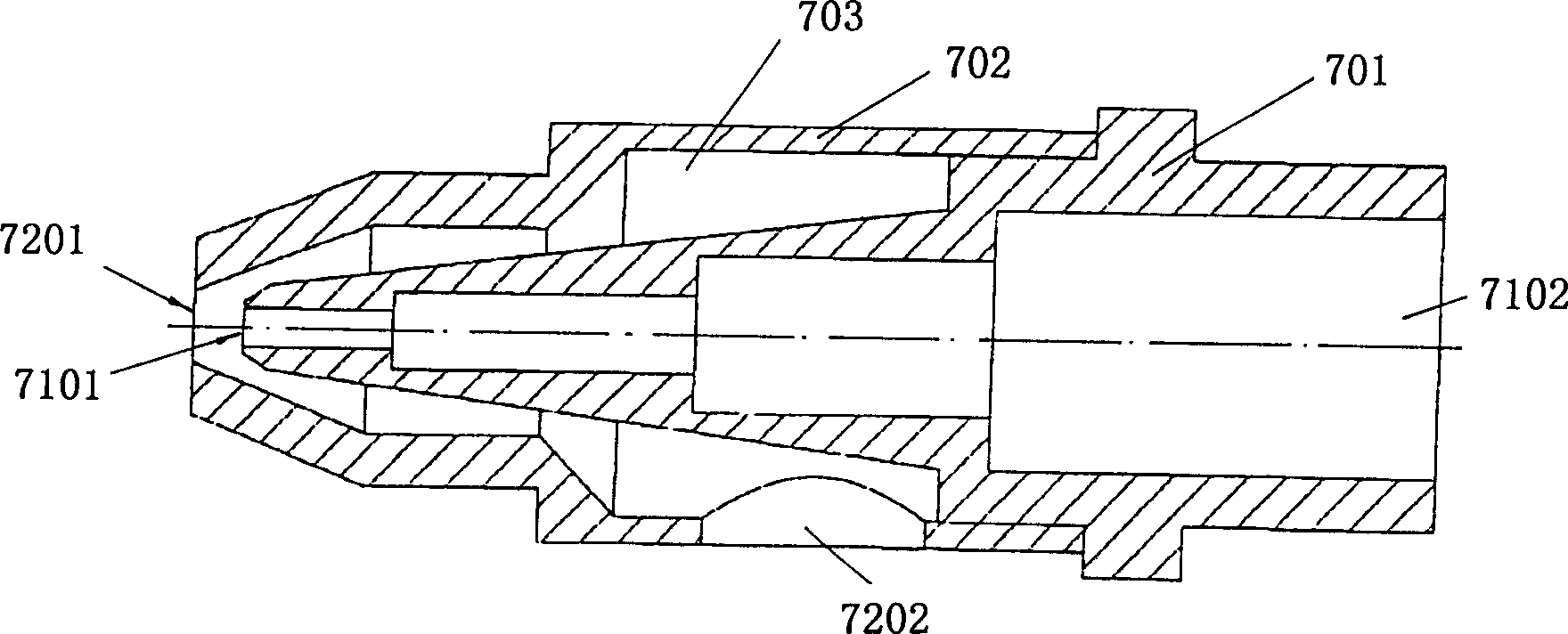

[0027] A dual gas source gas heater, including a housing 1 and a main control valve 2 installed in the housing 1 (the temperature control valve of model SIT545 or SIT544 can be used, and a manual valve can also be used to realize it), a burner 3 , the input end of the main control valve 2 is connected to the gas outlet of the dual pressure regulator valve 5, one inlet of the dual pressure regulator valve 5 is connected to the gas source, the other inlet is closed, and the main control valve 2 The output of the two-way input transfer switch 4 (its structure is as figure 2 As shown), the transfer switch 4 has two inputs and four outputs, the two inputs are respectively connected to high calorific value and low calorific value gas, and two of the four outputs are connected to the corresponding air inlet of the dual gas source nozzle 7 , the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com