Process for preparing high purity carbon monoxide gas by desulfurization of organic sulfur at low and normal temperature

A carbon monoxide and organic sulfur technology, which is applied in combustible gas purification, combustible gas purification/transformation, petroleum industry, etc., can solve problems such as air quality pollution, high investment and operating costs, unfavorable environmental protection, etc., to protect safety, improve and The effect of protecting the ecological environment and reducing the load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

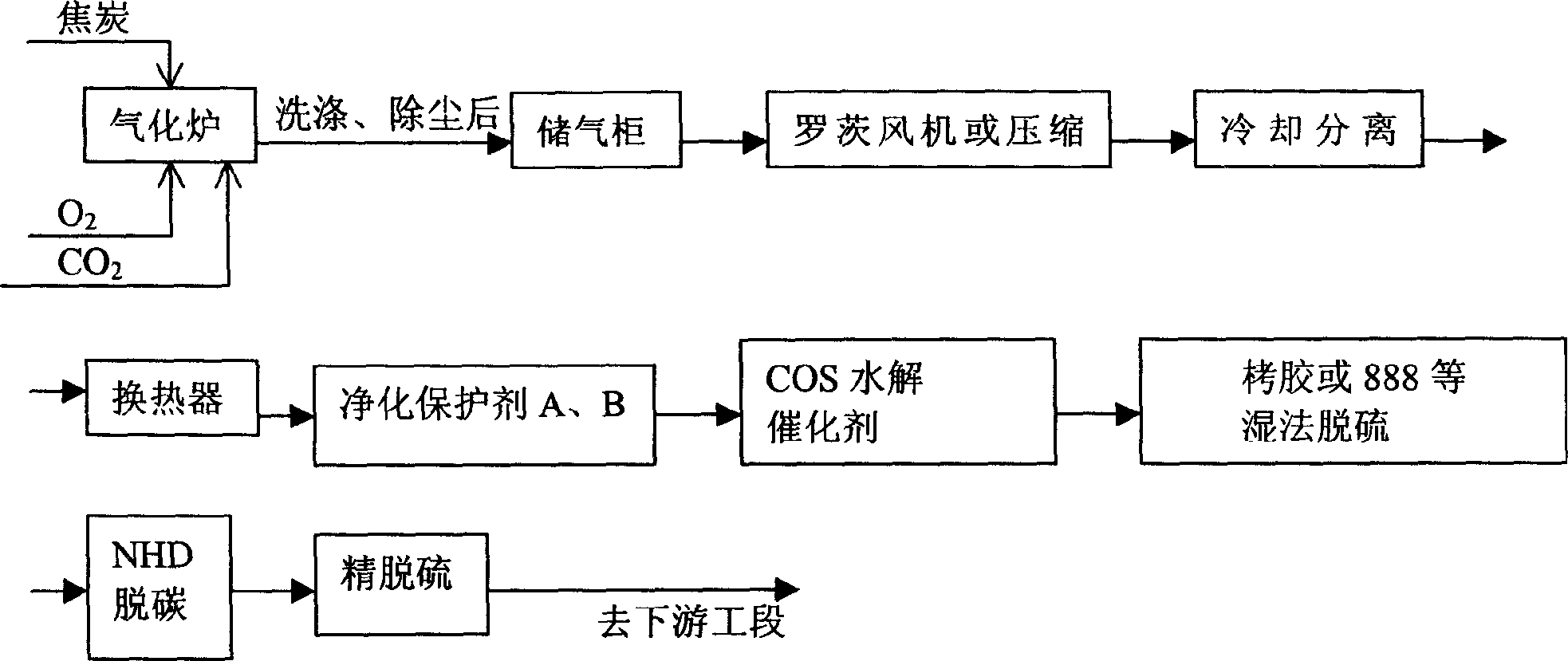

Method used

Image

Examples

Embodiment Construction

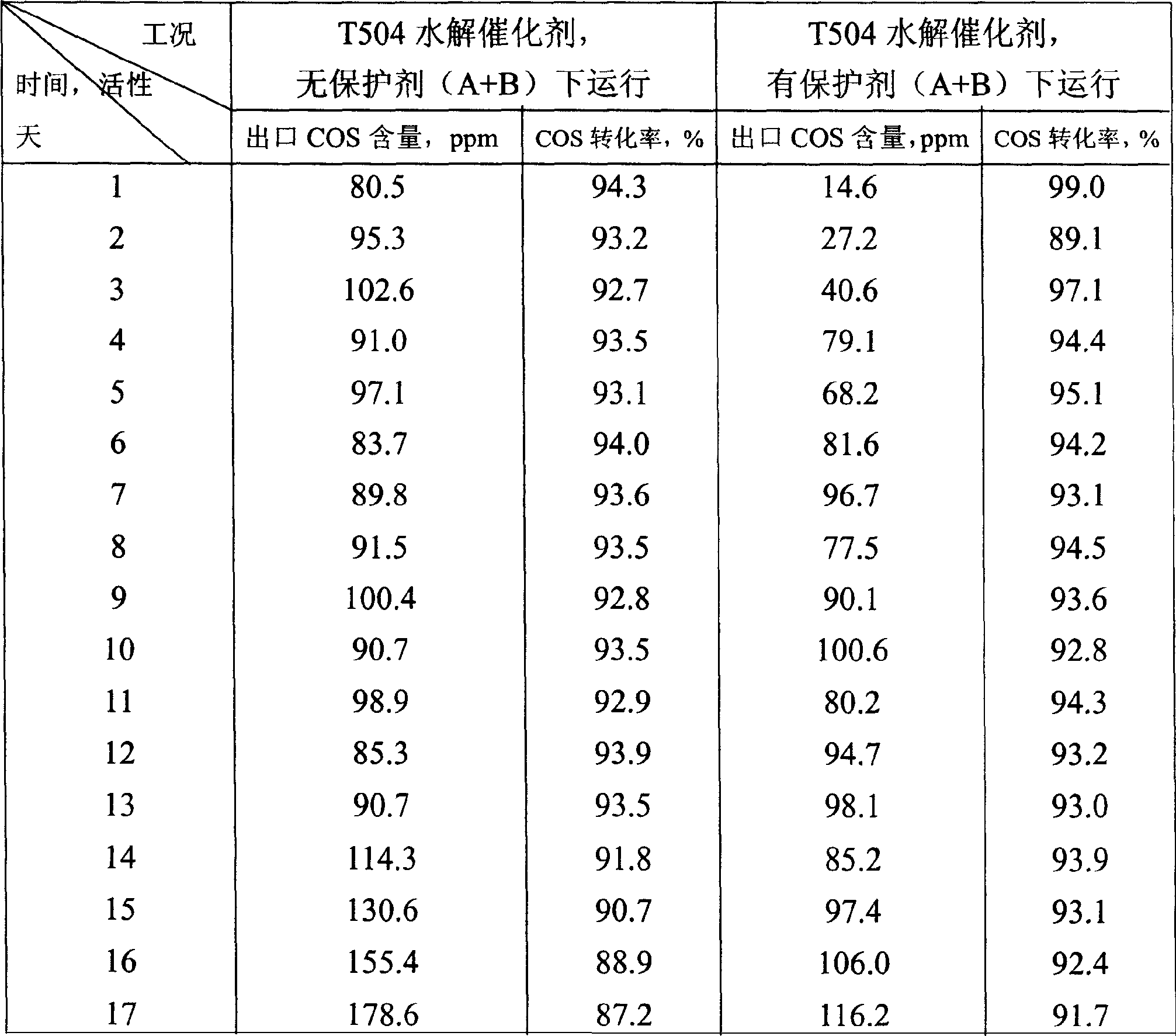

[0018] In order to observe the stability of T504 type COS hydrolysis catalyst with or without protective agent (A+B) to high content COS hydrolysis activity, experiments were carried out:

[0019] The method is to use special steel cylinder gas with COS-containing raw material gas to pass through T504 type COS hydrolysis catalyst, and use special steel cylinder gas with COS-containing raw material gas to pass through protective agent A+protective agent B first, and then through T504 COS hydrolysis catalyst to measure the hydrolysis of T504 type. The COS content at the catalyst outlet was used to compare the activity stability of the T504 hydrolysis catalyst with or without the protective agent (A+B).

[0020] Raw gas composition: CO 69.1% O 2 0.41% COS 1400ppm, HCl 60ppm, SO 2 120ppm,H 2 S 160ppm, H 2 O 3.4% CO 2 24.6%, Yu N 2 , because it is equipped with acid gases such as HCl, it must be distributed with special steel cylinders.

[0021] T504 type COS hydrolysis ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com