Composition of polyurethane permeable microporous thin layer and method for making same

A manufacturing method and air permeability technology, which are applied in the application field of polyurethane resin materials, can solve the problems of polyurethane resin being unable to obtain air permeability characteristics, disappearance of friction resistance characteristics, and stuffy wearing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

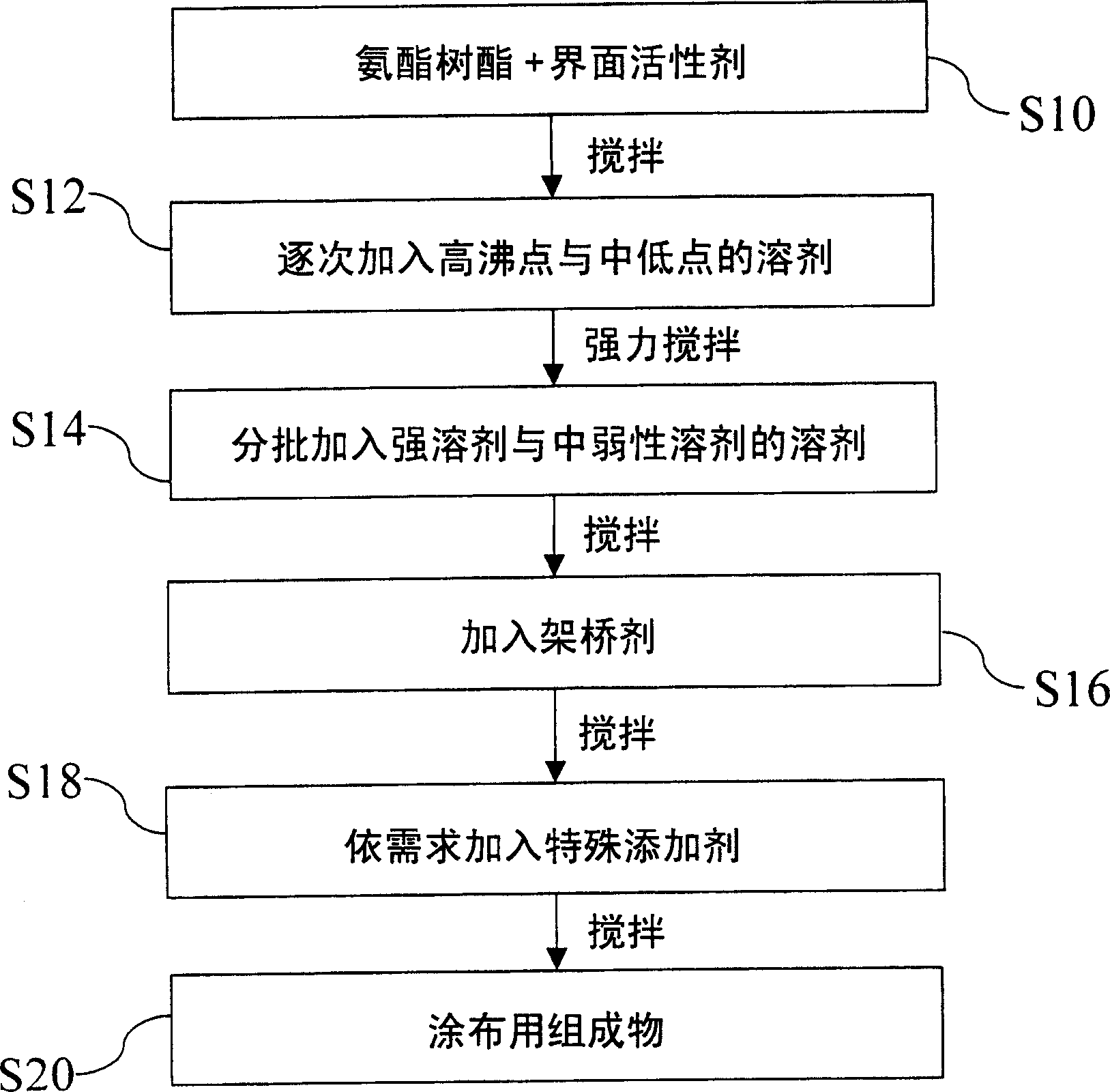

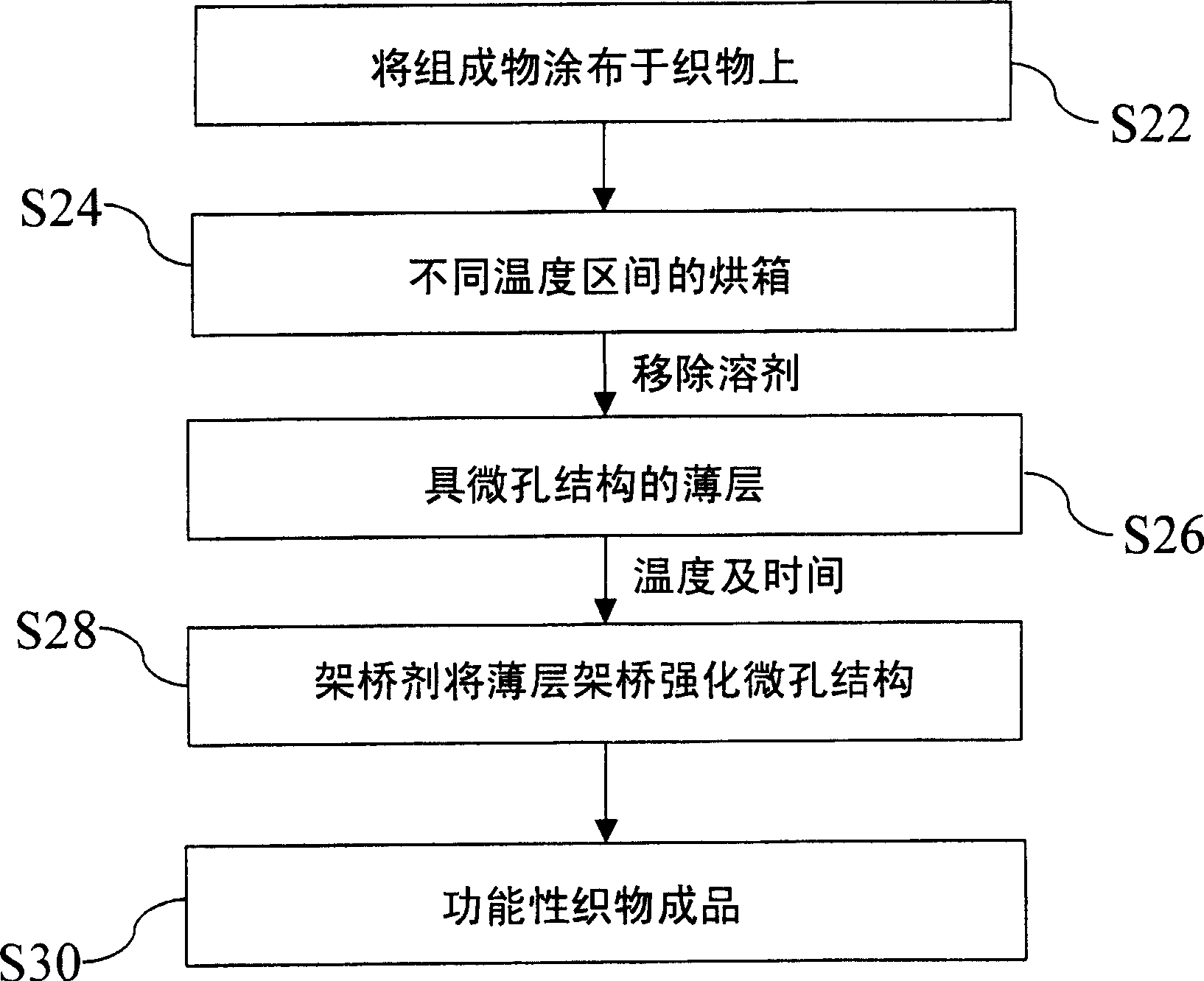

[0038] The main resin selected in the composition of the present invention is a polyether polyurethane (PU) resin, which is formed by polymerizing polypolyols with a repeating unit of more than four carbons, and the resin after the polymerization is completed, Mix and stir with the matching composition and order, and the weight percentage of pure resin accounts for 10 to 50 weight percent (%) in the whole composition; in addition, surfactants such as emulsifiers are mixed in the polyurethane resin, such as figure 1 In step S10 shown, in the presence of weak solvent, the polyurethane resin can be completely or incompletely emulsified to be coated with microcells and coexist with the weak solvent to present a homogeneous phase or microphase separation.

[0039] Next, as shown in step S12 and step S14, two or more solvents are successively added, which are respectively composed of a mixed solvent of a high-boiling point solvent and a medium-low boiling point solvent, and a mixed s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com