Nano hydroxy apalite/ fibroin-chitosan compound scaffold and its preparation method

A technology of nano-hydroxyapatite and silk fibroin, applied in medical science, prostheses, coatings, etc., can solve problems such as poor connectivity of stomata, unfavorable adhesion, differentiation, proliferation and growth of bone cells, and low porosity , to achieve good stomatal connectivity, good bone regeneration function, and high porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

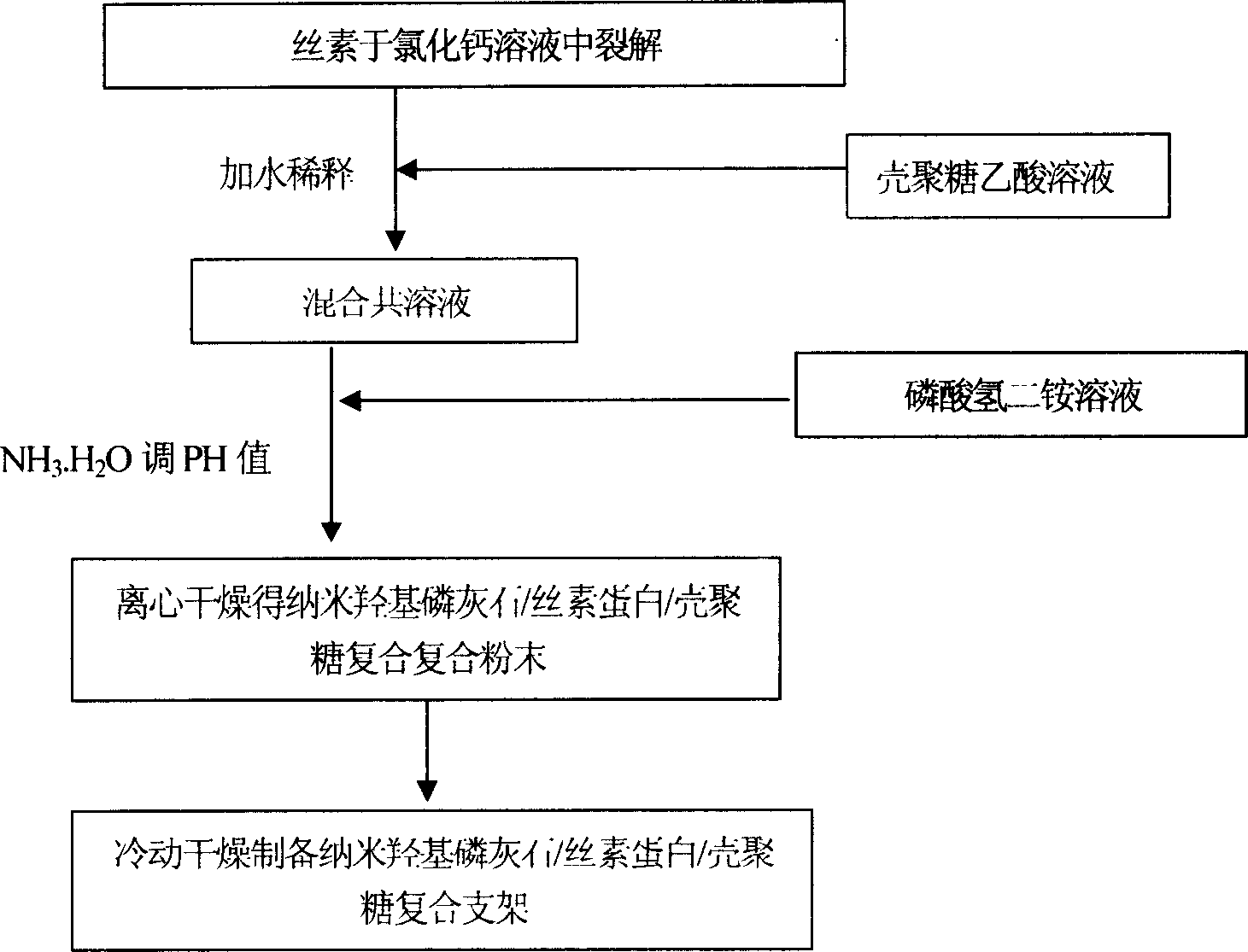

Method used

Image

Examples

specific Embodiment approach 1

[0021] Embodiment 1: The material of the nano-hydroxyapatite / silk fibroin-chitosan composite scaffold in this embodiment is composed of inorganic materials and organic materials. The inorganic material is nano-hydroxyapatite, and the organic material is For silk fibroin and chitosan, the weight ratio of inorganic material to organic material is 50-70:30-50, and the weight ratio of silk fibroin to chitosan is 1:1-2.

[0022] In this embodiment, the nano-hydroxyapatite is weakly crystalline, with a diameter of 4-6 nm and a length of 20-40 nm. The porosity of the composite support is 75%-90%, and the pore size is 150-500 μm.

specific Embodiment approach 2

[0023] Embodiment 2: This embodiment is different from Embodiment 1 in that the weight ratio of the inorganic material to the organic material is 50:50.

specific Embodiment approach 3

[0024] Embodiment 3: This embodiment is different from Embodiments 1 and 2 in that the weight ratio of the inorganic material to the organic material is 70:30.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com